Winder with winding speed slowing mechanism

A cord reel and line speed technology, which is applied in the field of cord reels with a mechanism for slowing down the reeling speed, can solve the problems of touching other objects, easily hurting users, falling off the power cord, etc., to improve safety and stability, the effect of reducing the take-up speed and slowing down the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

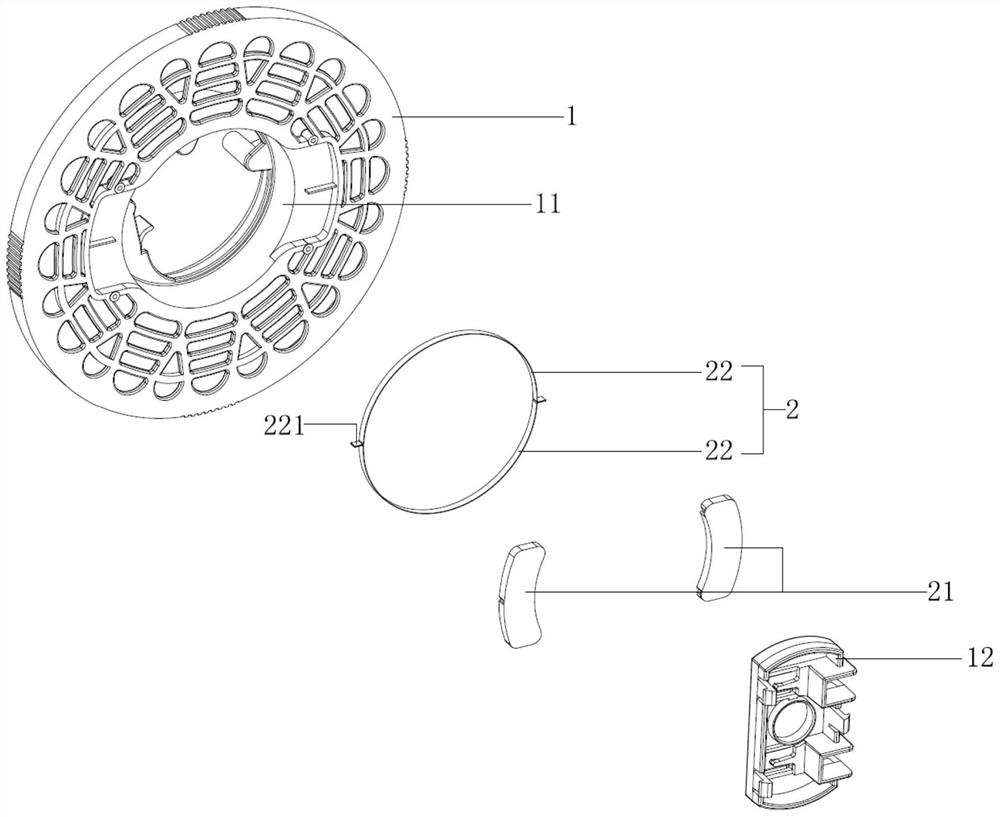

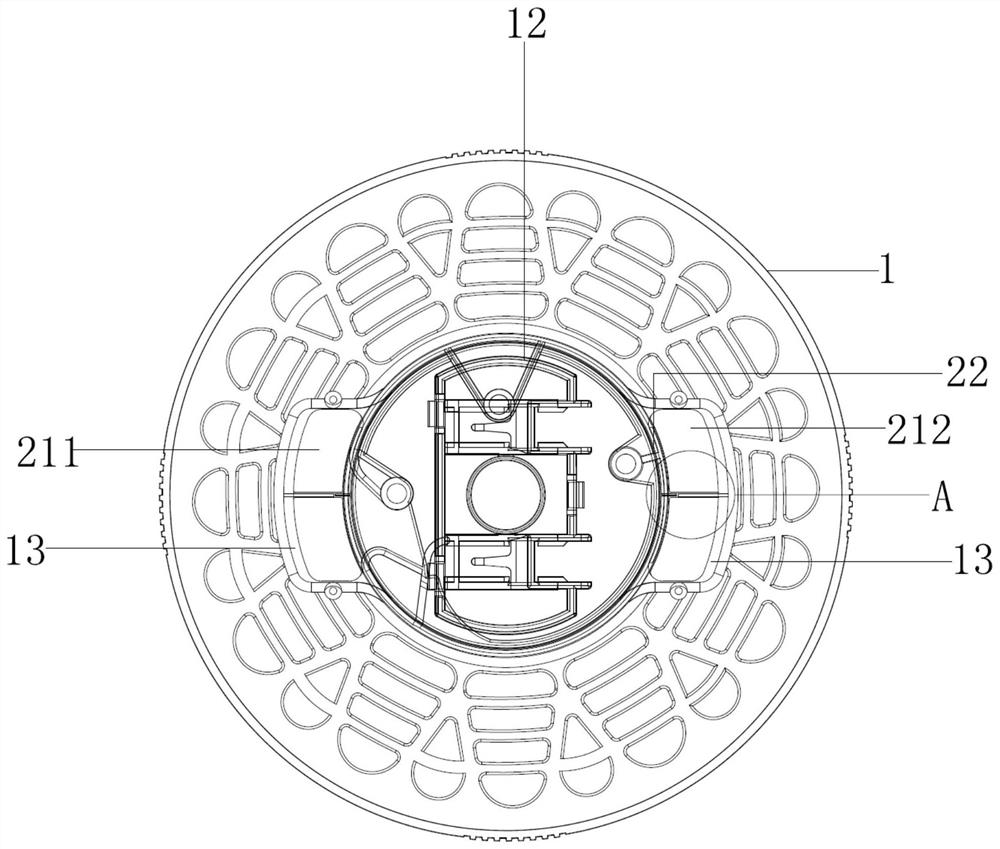

[0025] see Figure 1 to Figure 4 , the figure shows a wire reel provided by an embodiment of the present invention with a winding speed slowing mechanism, which mainly includes a wire reel 1 and a deformable ring 2, and the wire reel 1 is rotatably installed on On the winding support, the winding support has a support insert 12 embedded in the central circular hole 11 of the winding reel 1, and the deformable ring part 2 is installed in the central circular hole 11, and the outer edge of the circular ring part 2 Two brake parts 21 are fixedly connected, and the two brake parts 21 can specifically be a first brake pad 211 and a second brake pad 212, and the first brake pad 211 and the second brake pad 212 are equidistant along the circumferential direction of the annular member 2. distribution, the first brake pad 211 and the second brake pad 212 are slidably connected to the surface of the reel 1 at the same time, and the first brake pad 211 and the second brake pad 212 slide ...

Embodiment 2

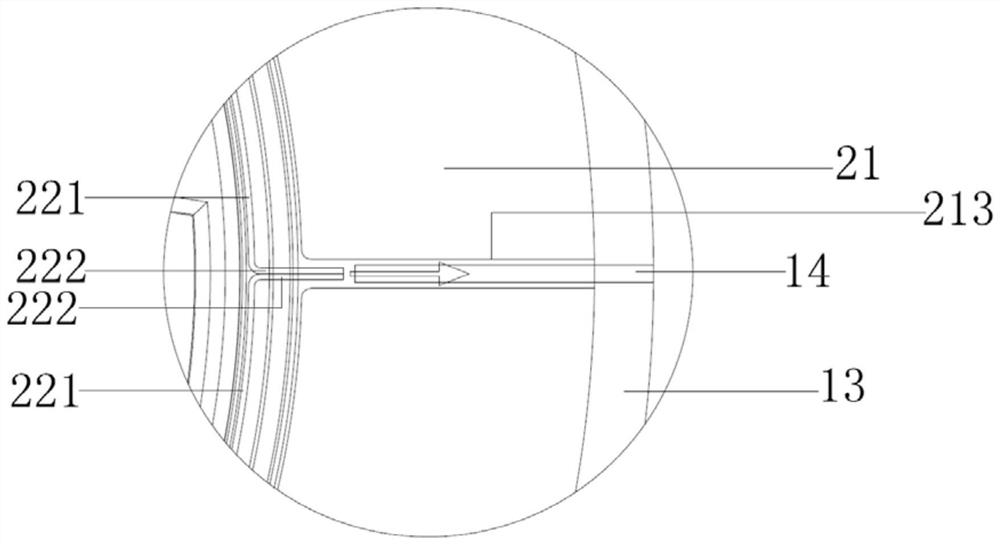

[0029] see Figure 1 to Figure 4 , the figure shows a wire reel with a wire take-up speed slowing mechanism provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The ring part 2 is formed by splicing two semicircular parts 22, and the joint of the two semicircular parts 22 extends outward to form a connecting part 221, and the connecting part 221 is fixedly connected to the brake part 21, specifically, the semicircular part 22 The ends of the two bent ends 222 are outwardly formed, and the two bent ends 222 are joined together to form a connecting part 221 .

[0030] Through the setting of the above structure, it is easy to install and disassemble the ring piece, and it is convenient for the brake component to pull the ring piece more evenly, so that it changes from a circle to an ellipse.

Embodiment 3

[0032] see Figure 1 to Figure 4 , the figure shows a wire reel with a wire take-up speed slowing mechanism provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The surface of the reel 1 is provided with a sliding cavity 13 for the sliding of the braking component 21, and the sliding cavity 13 is provided with sliding guide ribs 14 arranged radially along the reel 1, and the bottom of the braking component 21 is provided with a sliding connection. Slide groove 213 on the sliding guide rib 14. Through the setting of the above structure, the brake component can slide on a prescribed path, and the movement is more precise and stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com