Pay-off tightening device for high-performance fiber knitting machine

A high-performance fiber and weaving machine technology, applied in braided fabrics, textiles and papermaking, etc., can solve the problems of troublesome yarn fiber handling, yarn fiber breakage, and difficult yarn fiber connection, etc., to reduce the problem of excessive knotting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

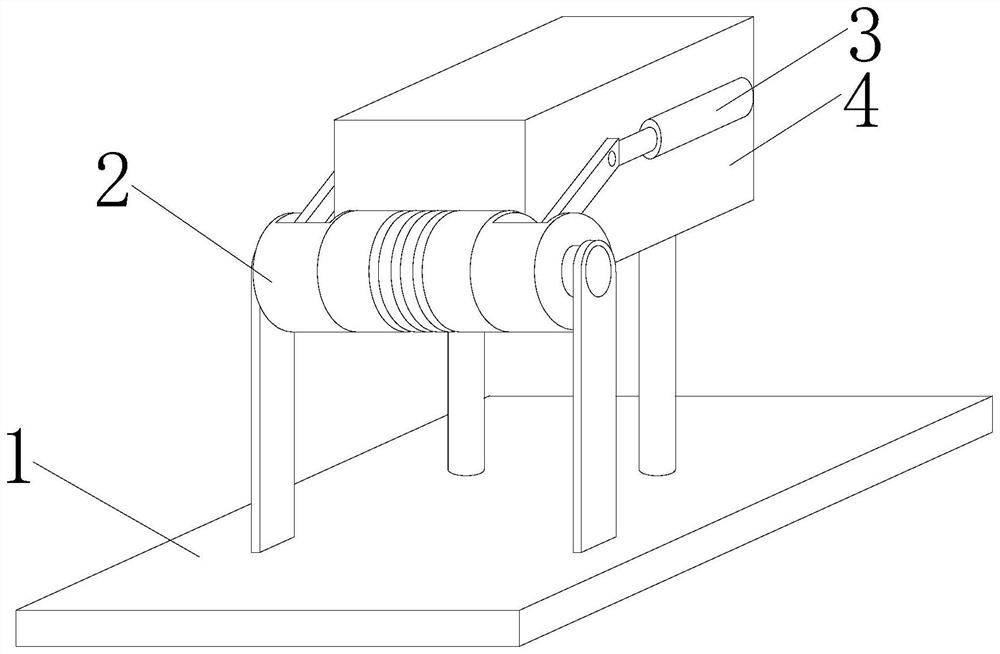

[0026] Example 1: A pay-off and tightening device for a high-performance fiber braiding machine, comprising a device main body 1, the top side of the device main body 1 is fixedly connected with an adjustment component 2 that can adjust the pay-off and tightening of textile fibers, and also includes a hydraulic The push rod 3 and the hydraulic push rod 3 are drive-connected with the adjustment assembly 2 .

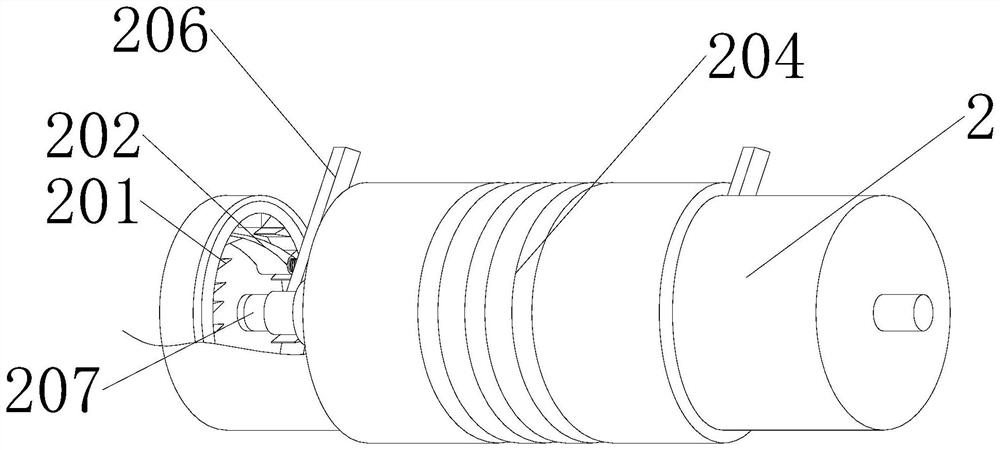

[0027] The two sides of the inner wall of the adjustment assembly 2 are fixedly connected with rotating teeth 201, the inner middle of the adjustment assembly 2 is fixedly connected with a connecting shaft 207, the outer surface of the connecting shaft 207 is fixedly connected with a connecting sleeve rod 206, and one side of the connecting sleeve rod 206 is fixedly connected There is a rotating tube 203 sleeved on the connecting shaft 207, the other side of the connecting sleeve rod 206 is connected with a fixed block 202, and one side of the outer surface of the fixed blo...

Embodiment 2

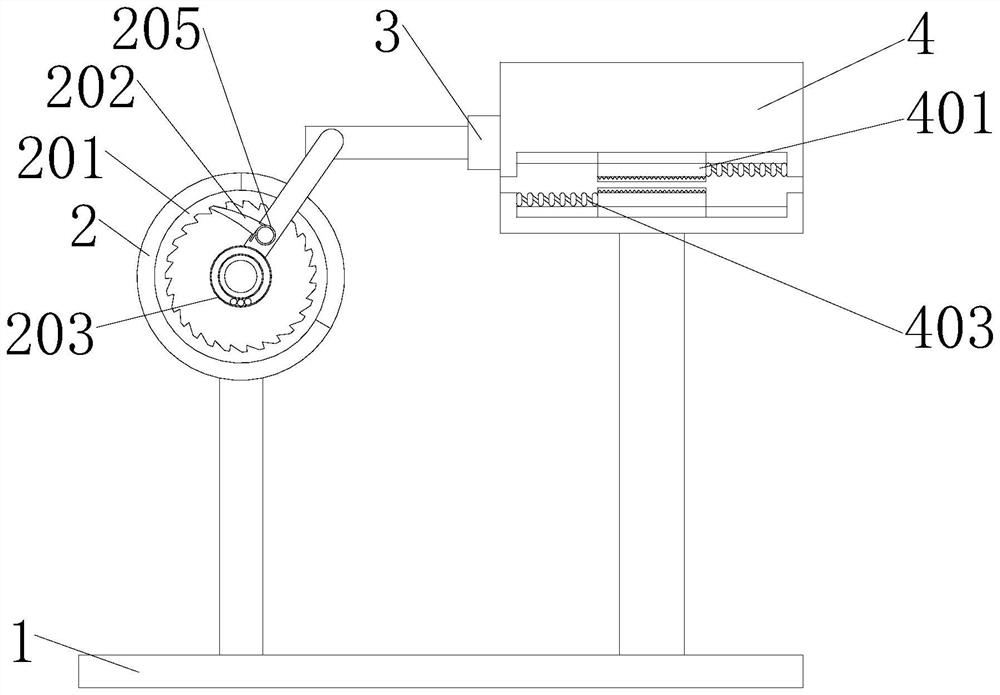

[0033] Example 2: The difference between Example 2 and Example 1 is that a moving component 4 is fixedly connected to the other side of the top of the main body 1 of the device, and the interior of the moving component 4 is provided with a cavity, which enables textile fibers to enter and fix them;

[0034] A protection box 401 is connected inside the moving assembly 4, a protection block 402 is fixedly connected to the top of the protection box 401, and a movable spring 403 is fixedly connected to one side of the protection box 1;

[0035] There are two protective boxes 401. The two protective boxes 401 are arranged in mirror images of the horizontal axis of the moving component 4. The protective blocks 402 are made of rubber material, and are provided with a plurality of protective blocks 402. distance state arrangement;

[0036] Wherein: when one end of the textile fiber enters the interior of the moving component 4, and the other end exits the moving component 4, and a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com