Seepage analysis method considering secant pile defects

An analysis method and technology for occlusal piles, which are applied in the fields of excavation, special data processing applications, geometric CAD, etc., can solve the problems of lack of analysis models and methods, and the inability of occlusal pile defects to affect judgment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

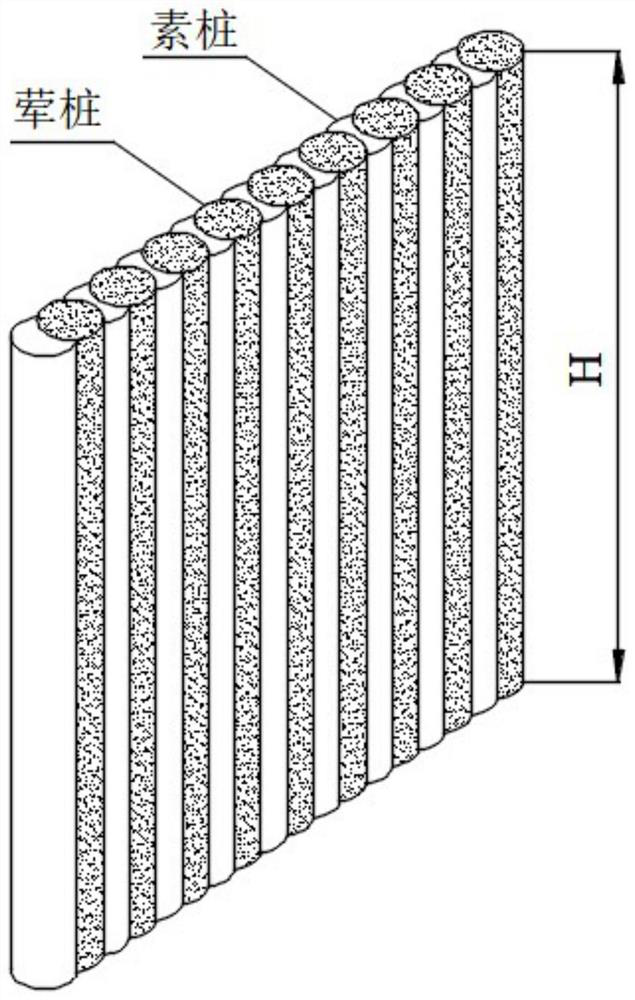

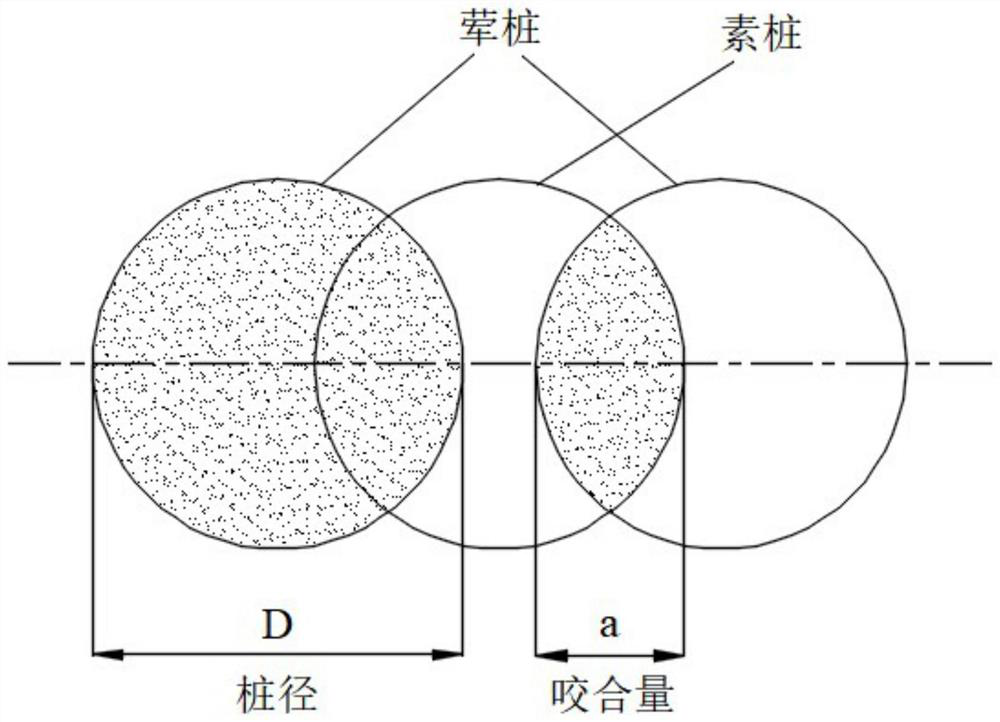

[0027] like Figure 1-6 As shown, the embodiment of the present invention provides a seepage analysis method considering the defects of occlusal piles, including the following steps:

[0028] S1. Design and manufacture of defect-free pile model S-1

[0029] There are no defects in this model. As an initial model, the diameter of the occlusal pile model is the design diameter D, the occlusal amount is the design size a, and the length of the pile body is the design length H. The schematic diagram of the model is as follows figure 1 , figure 2 shown;

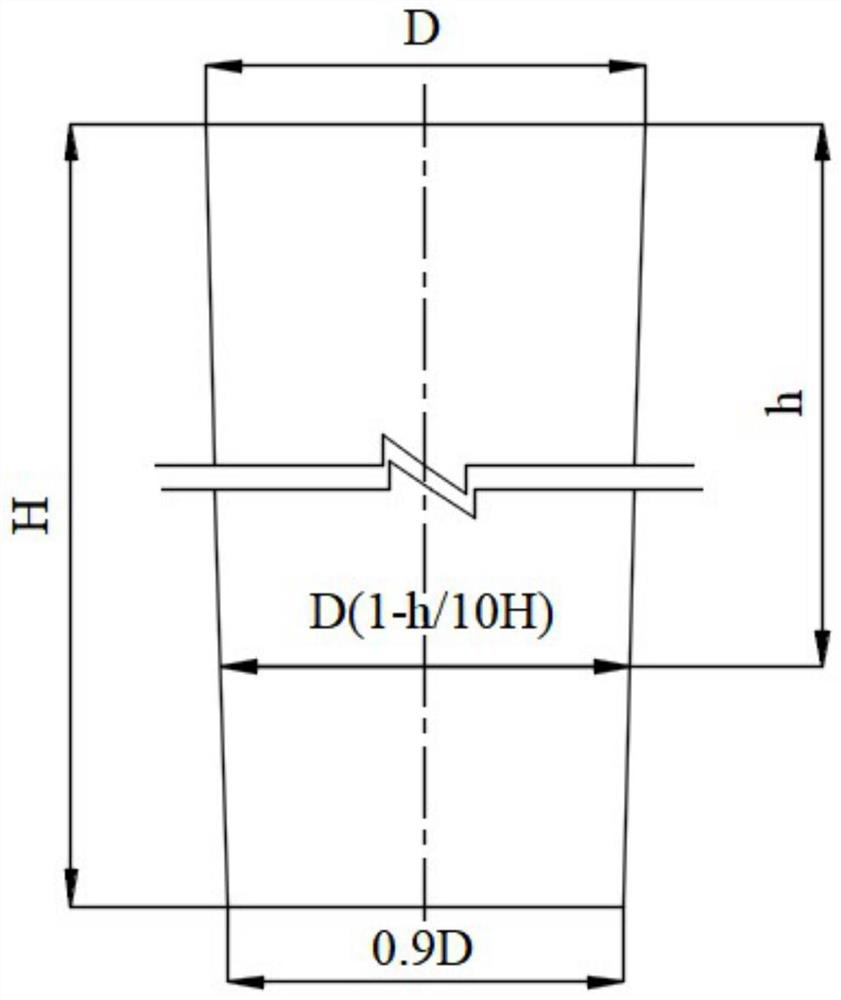

[0030] S2. Design and make diameter defect model S-2

[0031] As the depth increases, it becomes more difficult to control the accuracy of the pile diameter. The diameter of the occlusal pile becomes smaller as the excavation depth increases. The diameter of the pile top in this model is the design diameter D, and the diameter of the pile bottom is 0.9D. The increase of the depth decreases linearly, then the pile diameter at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com