A safe casing operation method suitable for leaky formations

A casing and formation technology, which is used in drilling equipment and methods, earth-moving drilling, drilling equipment, etc., can solve the problem that the movement speed is not enough to meet the operation requirements of the narrow safe density window and the balance pressure criterion, the annular gap is small, and the well problems such as temperature and high temperature, to achieve the effect of rich technical measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the safe casing operation method suitable for leaky formations according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

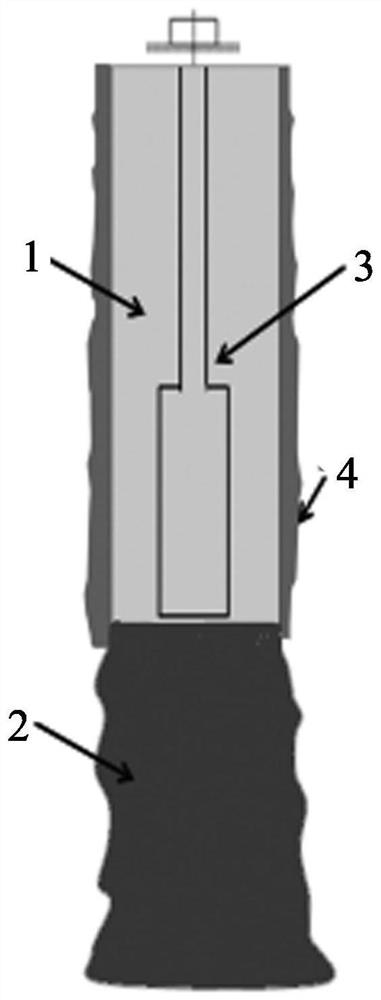

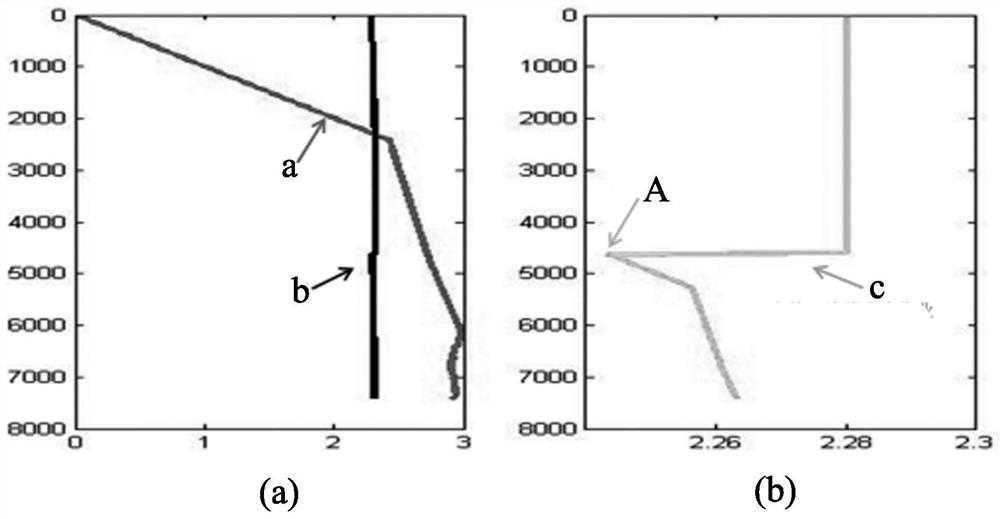

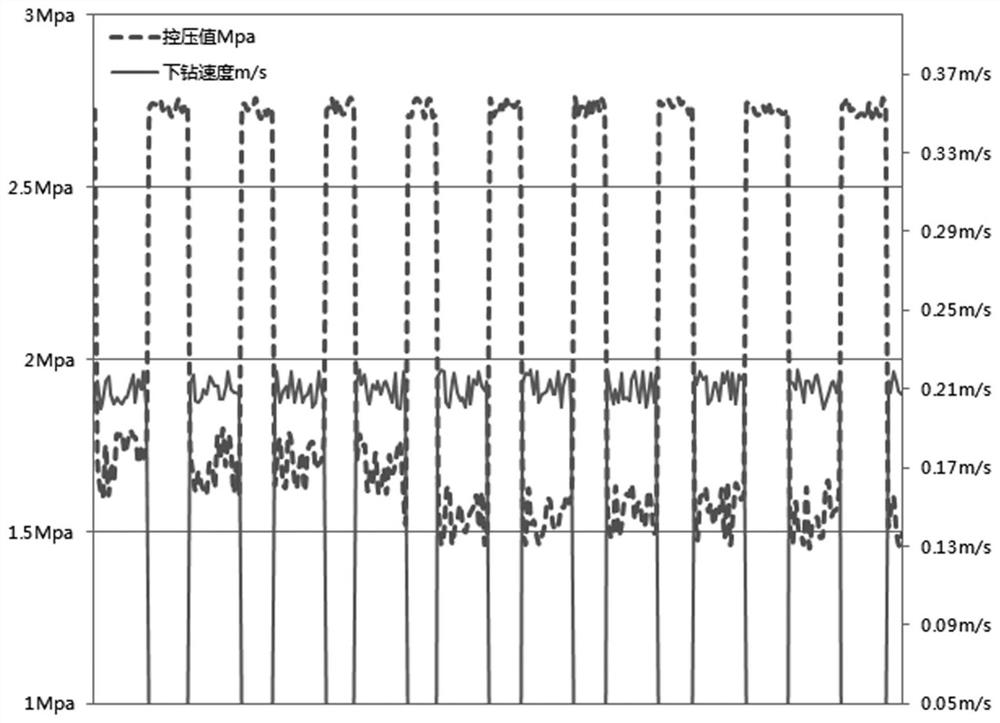

[0017] figure 1 A schematic diagram of the structure of the drilling fluid slurry column during the period of selecting a suitable well depth range to adjust the drilling fluid density according to an exemplary embodiment of the present invention is shown. figure 2 Shows a schematic diagram of drilling fluid equivalent density control during casing running in Example 1; where figure 2 (a) represents the change trend of drilling fluid equivalent density control curve and excited pressure, curve a represents the change curve of excited pressure, and curve b represents the control line of drilling fluid equivalent density, figure 2 (b) represents the change curve of the static equivalent density at the bottom of the casing during running in, curve c represents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com