Aluminum alloy window frame sealing drainage structure

A drainage structure, aluminum alloy technology, applied in the direction of sealing device, condensate water discharge, etc., can solve the problems of water backflow, water seepage, peculiar smell, etc., to achieve the effect of improving the speed of drainage and avoiding inward leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

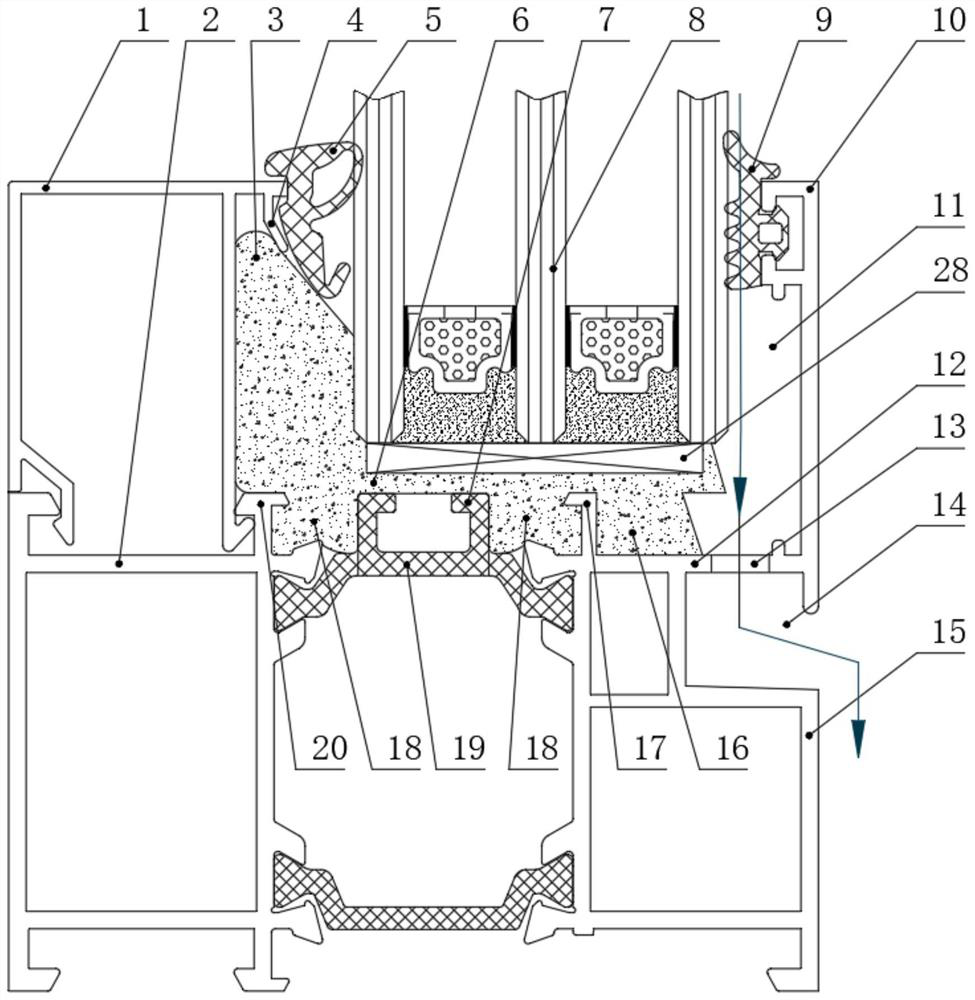

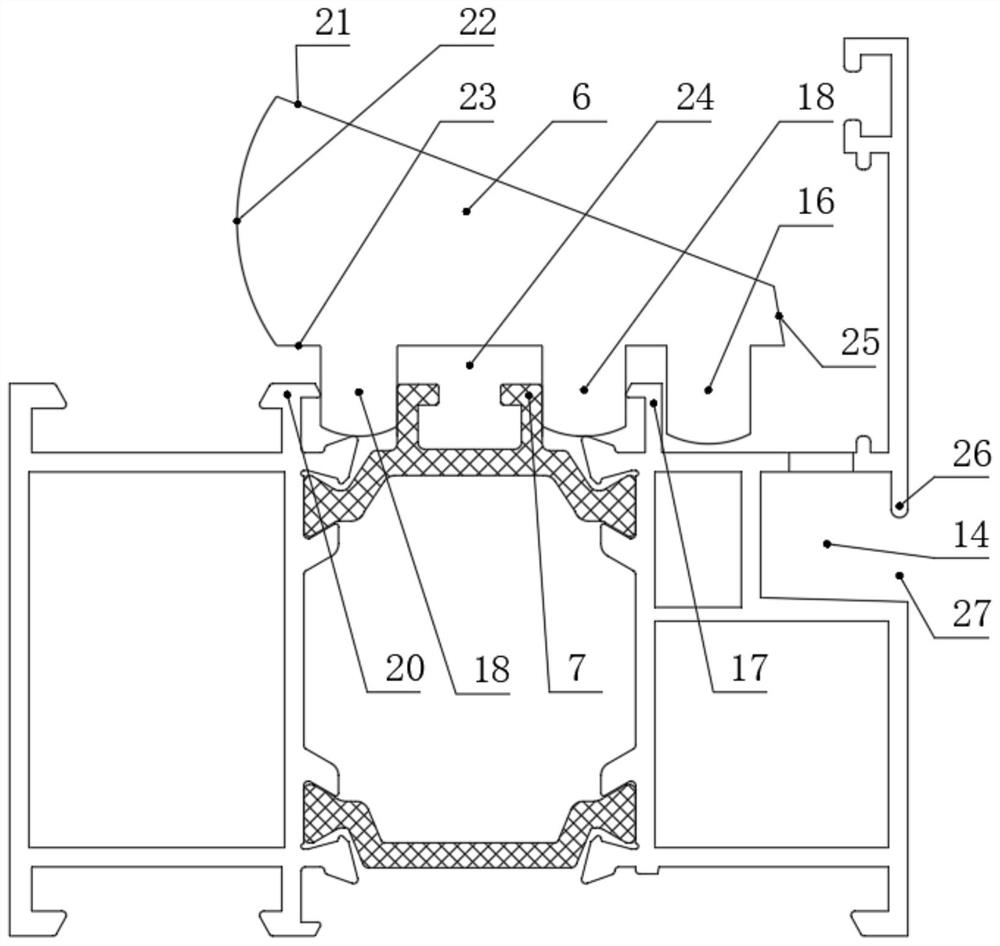

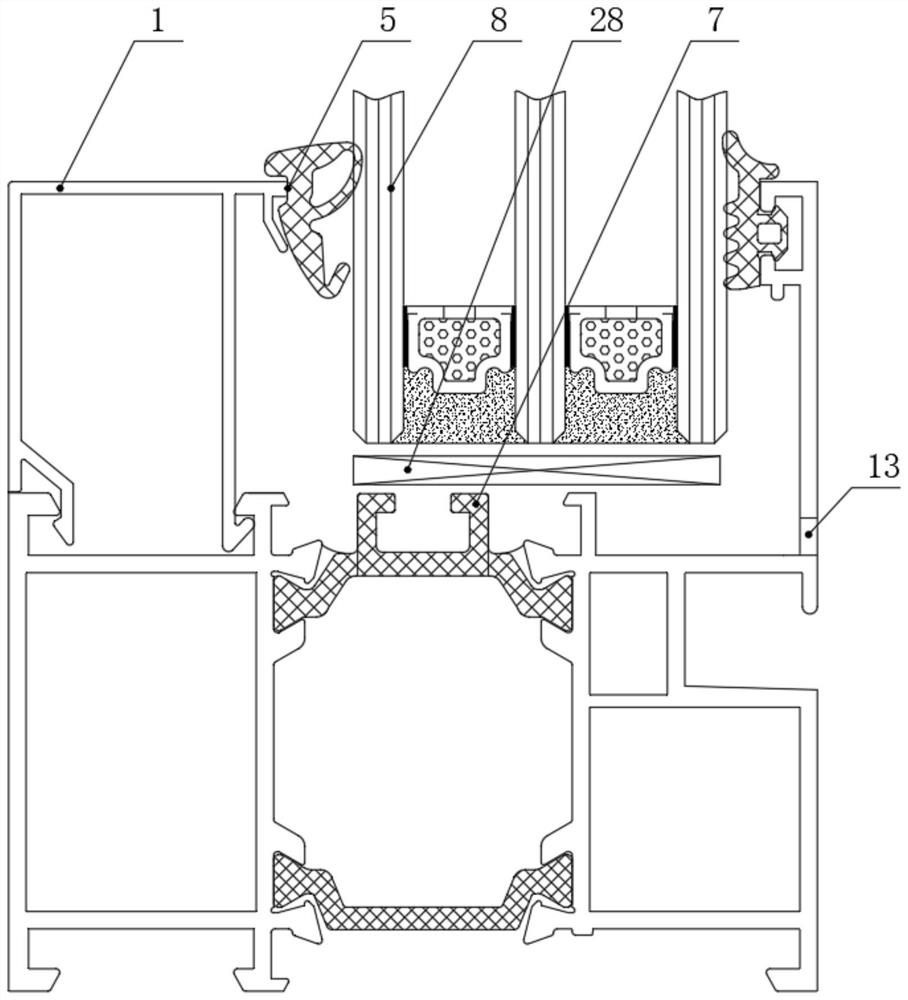

[0022] An aluminum alloy window frame sealing drainage structure, such as Figure 1~3 As shown, the window frame includes an inner frame 2, a connector 19 and an outer frame 15, the inner frame and the outer frame are respectively connected to both sides of the connector, glass 8 is arranged in the window frame, and a buckle is arranged between the inner frame and the inner surface of the glass. Article 1, the innovation of the present invention is that: an opening 13 is set on the outer frame side 12 inside the outer extension edge 10 of the outer frame, and a groove 14 is arranged on the outer surface of the outer frame below the opening, and the opening and the groove make the glass , the space 11 between the side of the outer frame an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com