Automobile LED lamp assembly detection and identification machine, detection and identification system and method

An LED lamp assembly and LED lamp technology, which are used in lamp testing, machine/structural component testing, and electrical measurement, etc., can solve the problems of exposed lines, easy detachment of labels, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The specific embodiments and working principles of the present invention will be described in further detail below with reference to the accompanying drawings.

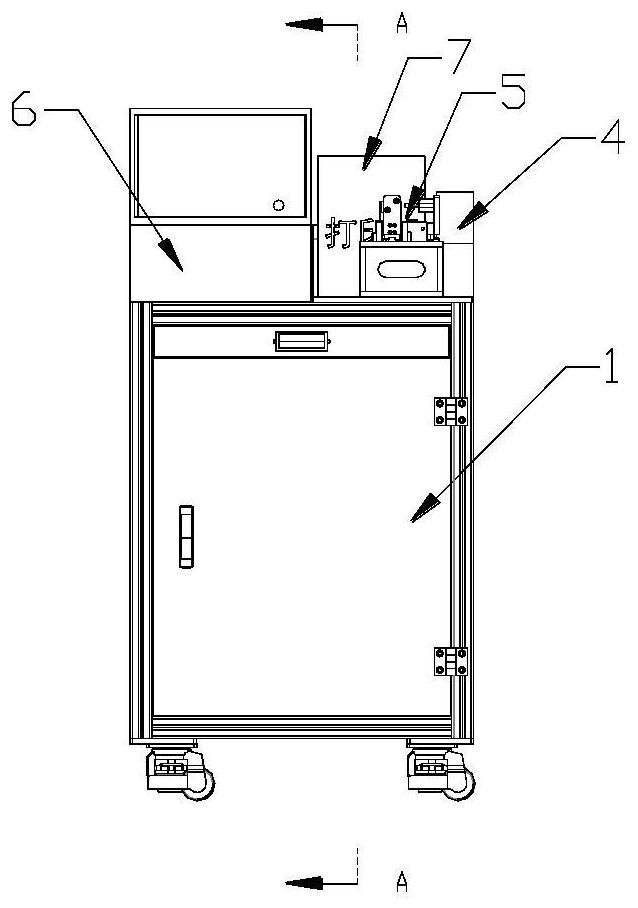

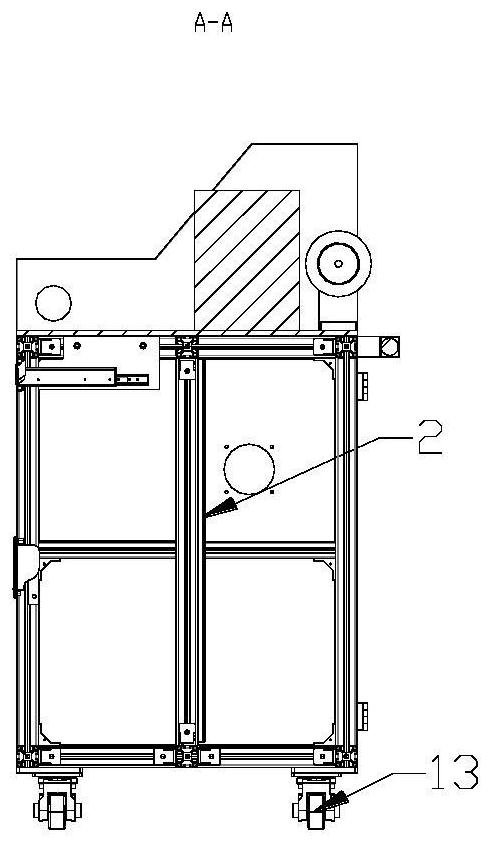

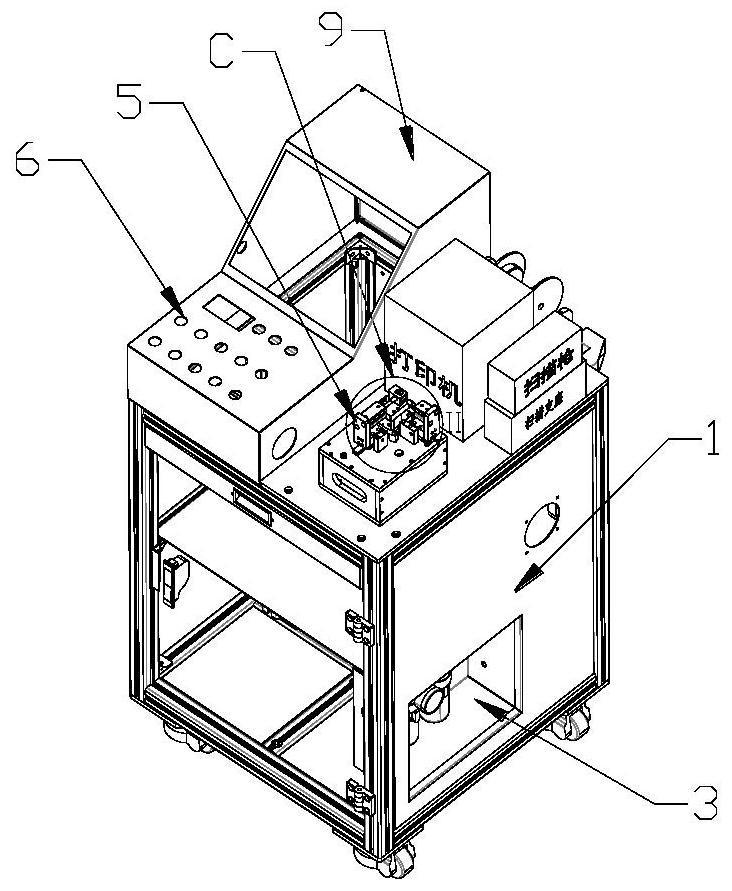

[0043]An automobile LED lamp assembly detection and recognition machine, combinedFigure 1-5It can be seen that it includes a cabinet 1 in which a power distribution box 2 and an air source box 3 are provided; the top surface of the cabinet 1 is provided with a scanner unit 4, an LED lamp clamping mechanism 5, and an LED lamp The performance checking and confirming mechanism 6 and the printer group 7 are arranged directly above the distribution box 2 and the two are connected.

[0044]In this embodiment, in combination with 3, it can also be seen that the printer group 7 includes a printer and a printing paper installation roller. inimage 3 , The printing paper installation rollers are arranged side by side beside the LED lamp performance detection and confirmation mechanism 6. In this embodiment, combiningimage 3 withFigure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com