Pressing device for garment manufacturing and using method thereof

A technology of garment manufacturing and pressing device, which is applied in the field of pressing device for garment manufacturing, which can solve problems such as accidents in finishing fabrics, and achieve the effect of improving safety and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

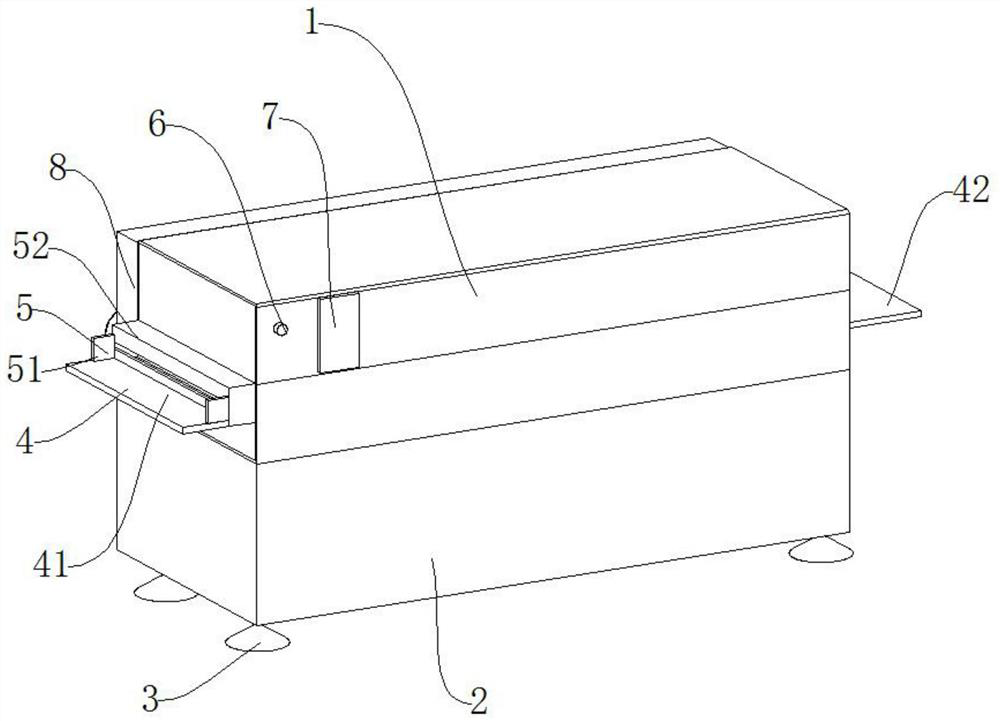

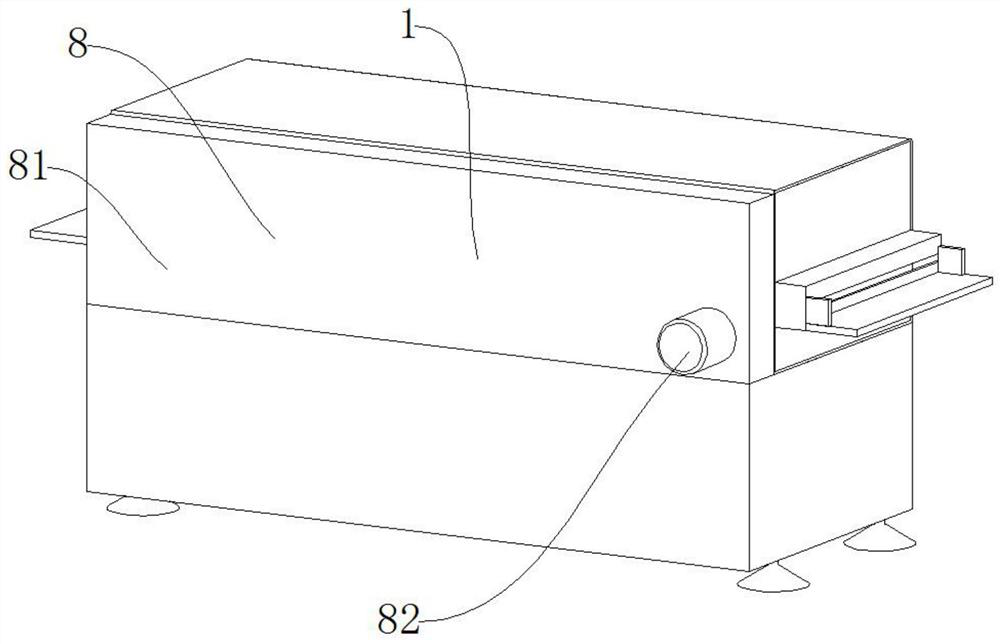

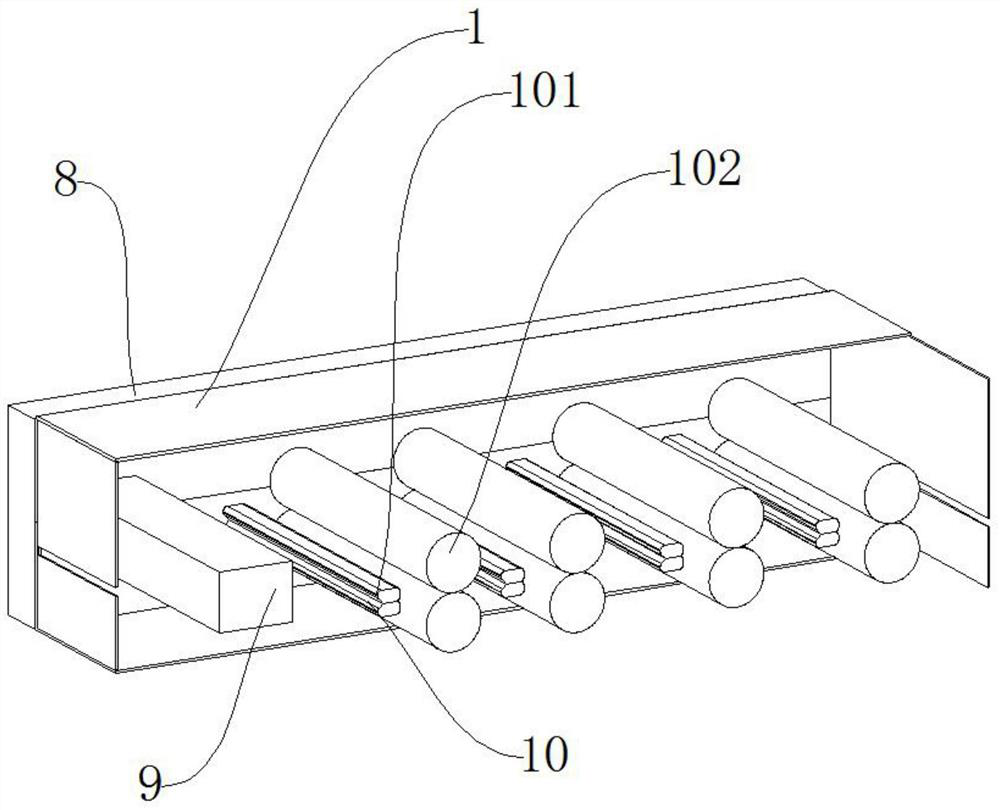

[0039] Such as Figure 1-Figure 7As shown, the pressing device for clothing manufacturing includes an upper shell 1, a lower shell 2, a shock absorber 3, an emergency stop button 6, a controller 7, and also includes a support mechanism 4, a safety mechanism 5, a transmission mechanism 8, an adjustment Mechanism 9, internal pressing mechanism 10, the lower end of the upper shell 1 is provided with a lower shell 2, the upper shell 1 and the lower shell 2 play a role of protection and support, and the lower end of the lower shell 2 is provided with a shock absorber 3 for shock absorption The seat 3 acts as a shock absorber, the rear end of the upper housing 1 is connected to the transmission mechanism 8, and the transmission mechanism 8 plays a transmission role, and the two sides of the lower housing 2 are provided with a support mechanism 4, and the support mechanism 4 plays a supporting role, and one side of the support mechanism 4 A safety mechanism 5 is provided, and the saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com