Air purifying agent, preparation system and preparation method

An air purifier and preparation system technology, applied in conveyors, grain processing, mechanical conveyors, etc., can solve the problems of quantitative crushing and processing of air purifiers, and achieve the effect of efficient and continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

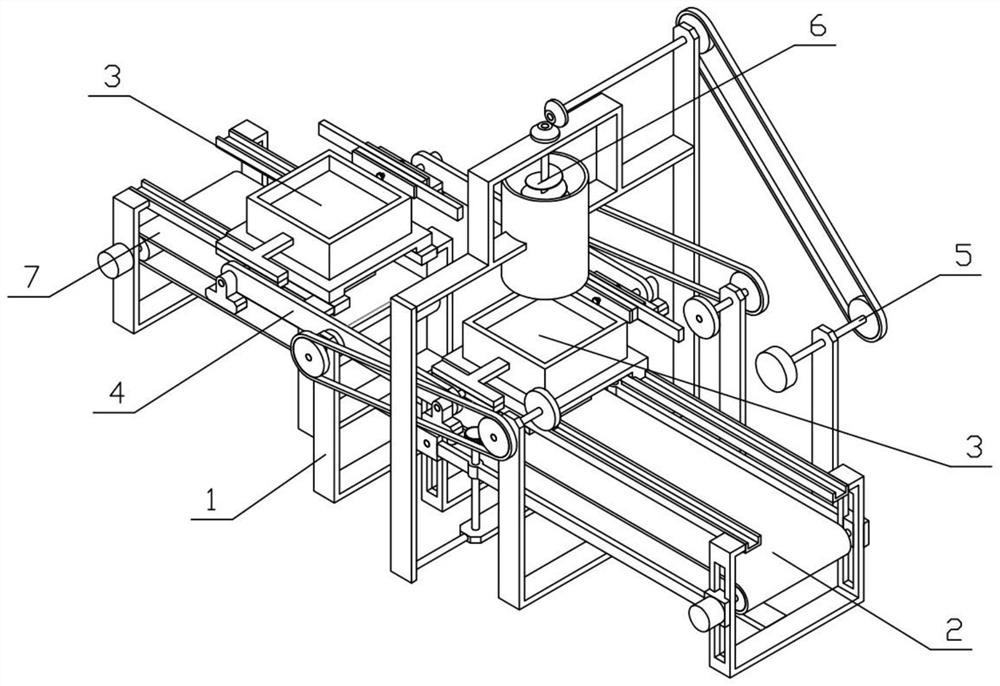

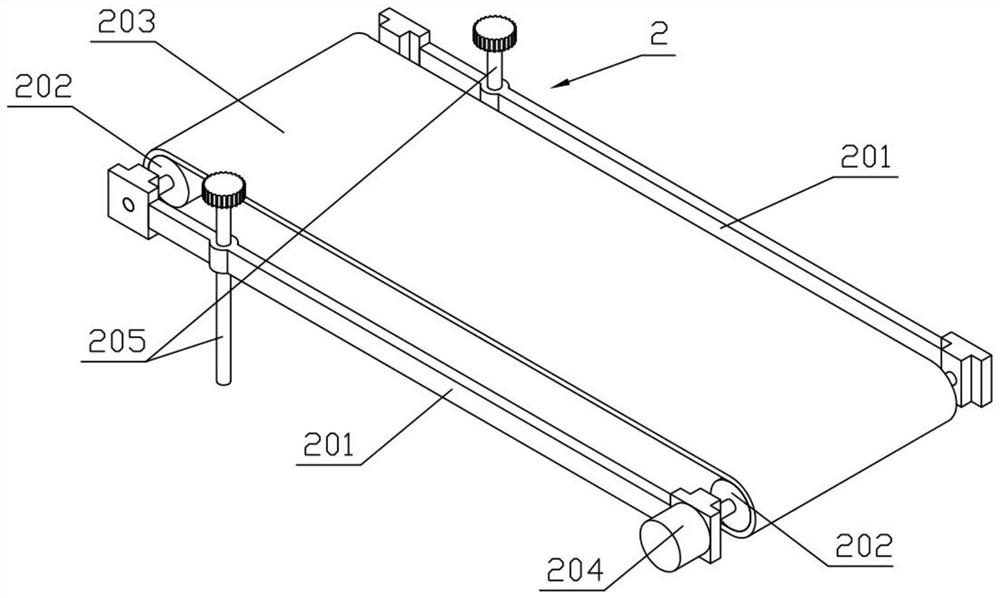

[0037] Combine below Figure 1-9Describe this embodiment, an air purifier preparation system, including a processing support 1, a transport mechanism I2, a storage mechanism 3, a transmission mechanism 5 and a crushing mechanism 6, and the transport mechanism I2 includes a transport side plate 201, a transport wheel I202 and a transport Belt I203, two transport side plates 201 are rotatably connected to the processing support 1, and transport wheels I202 are rotatably connected between the front and rear ends of the two transport side plates 201, and the two transport wheels I202 are connected by transmission belt I203 The storage mechanism 3 includes a storage slide 301, a storage cavity 302, a weight base plate 303, a push column 304 and a friction plate 305. The storage slide 301 is slidably connected to the processing support 1, and the storage slide 301 is fixedly connected with a storage cavity 302. A weight base plate 303 is slidably connected in the cavity 302, a push ...

specific Embodiment approach 2

[0039] Combine below Figure 1-9 Describe this embodiment, this embodiment will further explain the first embodiment, the storage mechanism 3 also includes a friction strip I 306, a friction strip II 307 and a locking screw 308, and one side of the storage cavity 302 is fixedly connected to the friction strip I 306. The other side of the cavity 302 is slidingly connected with two friction strips II 307, and the other side of the storage cavity 302 is threadedly connected with two locking screws 308, and the inner sides of the two locking screws 308 are connected with the two friction strips II 307 respectively. Contact: adjust the relative distance between the two friction strips II 307 so that the two friction strips II 307 drive the transmission mechanism 5 to rotate, the transmission mechanism 5 drives the crushing mechanism 6 to rotate, and the change in length between the two friction strips II 307 controls the crushing mechanism 6. During the working time, control the cr...

specific Embodiment approach 3

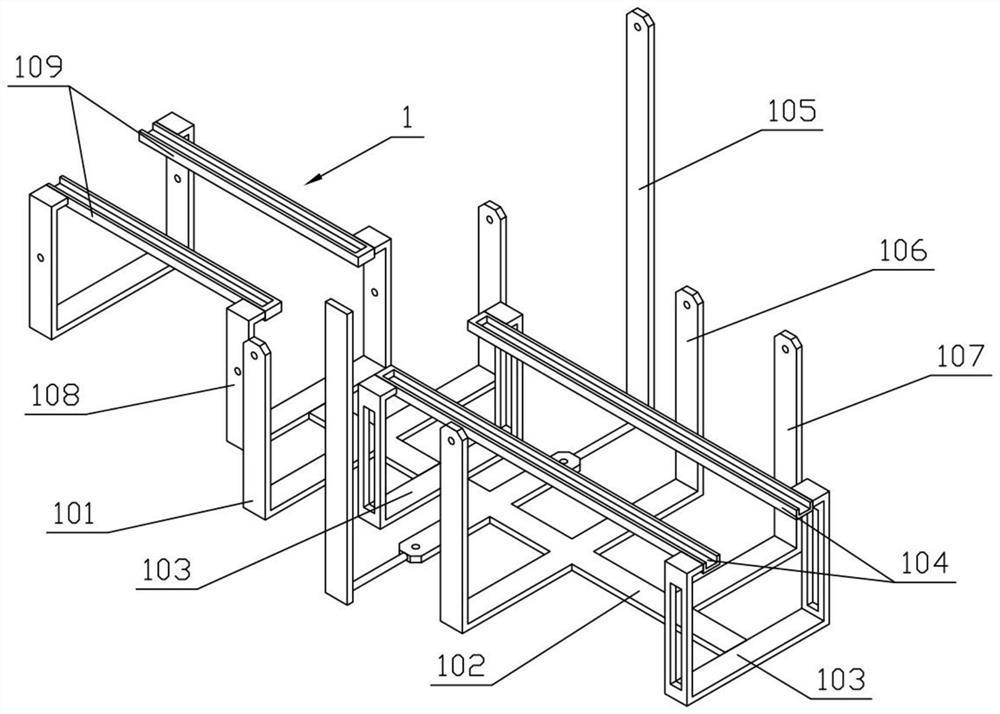

[0041] Combine below Figure 1-9 Describe this embodiment, this embodiment will further explain the second embodiment, the processing support 1 includes a flip support 101, a bottom support 102, a transport support I 103, a slide rail I 104, a crushing support I 105, a transmission support I 106, a transmission support II 107, The transport bracket II 108 and the slide rail II 109, the front end of the overturn bracket 101 is fixedly connected with the bottom bracket 102, the front and rear ends of the bottom bracket 102 are fixedly connected with the transport bracket I 103, and the left and right sides of the two transport brackets I 103 are fixedly connected with The slide rail I104, the bottom bracket 102 are fixedly connected with the crushing bracket I105, the transmission bracket I106 and the transmission bracket II107, the rear end of the turning bracket 101 is fixedly connected with the transportation bracket II108, and the left and right sides of the transportation br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com