An automatic track-changing classification device and classification method according to the thickness of the plate

A sorting device and plate technology, which is applied in the field of automatic track-changing sorting device according to the thickness of the plate, which can solve the problem that the plates cannot be classified with the same thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

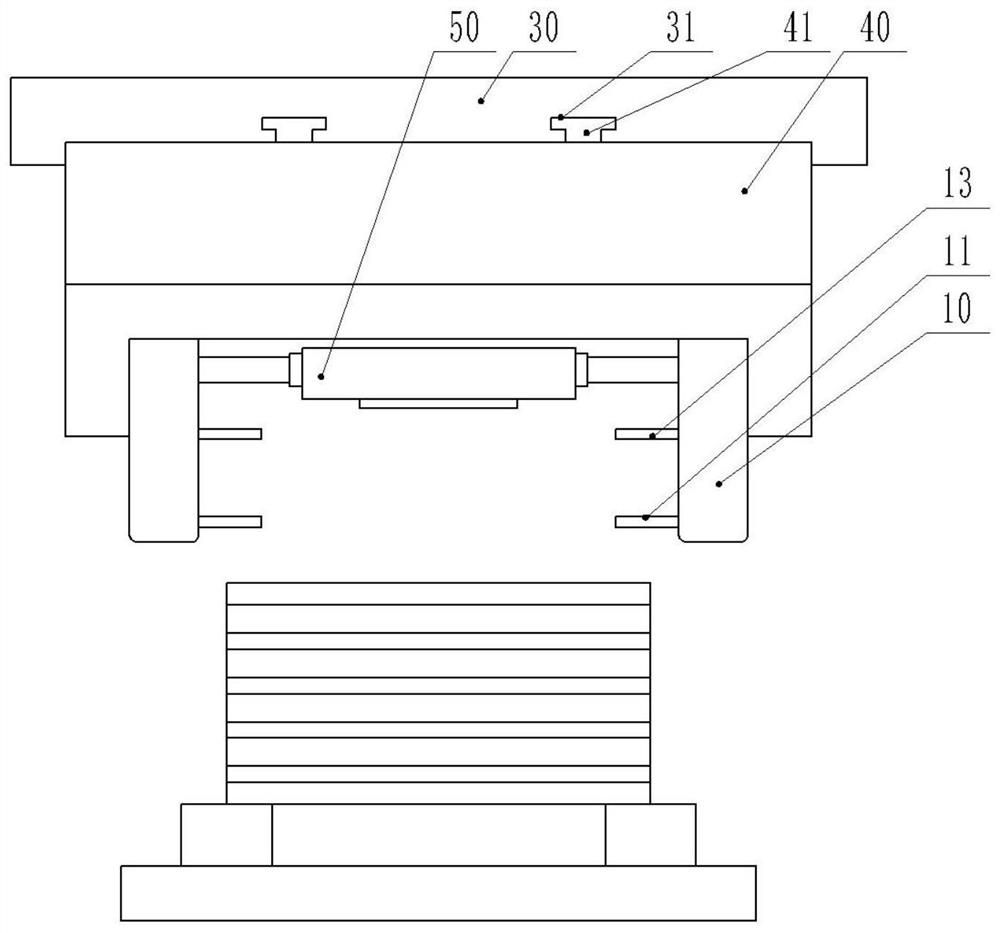

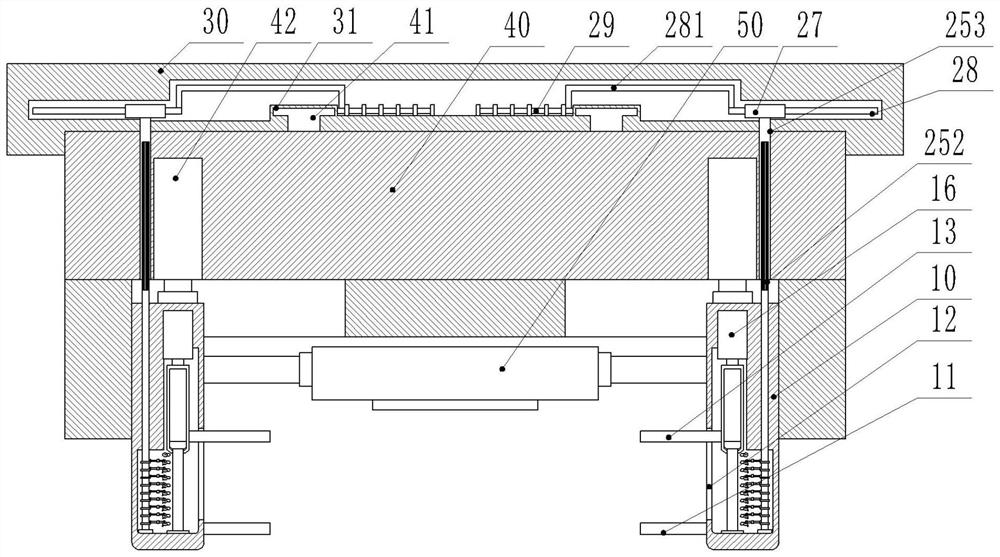

[0077] An automatic track-changing classification device according to the thickness of the plate, wherein, such as figure 1 As shown, it includes: a sliding mechanism 30 , a mounting base 40 , a clamping mechanism 10 , and a track changing mechanism 20 .

[0078] Such as figure 1 , 2 As shown, the sliding mechanism 30 has a guide rail, and the mounting seat 40 has a slider 41, and the slider 41 is slidably connected to the guide rail.

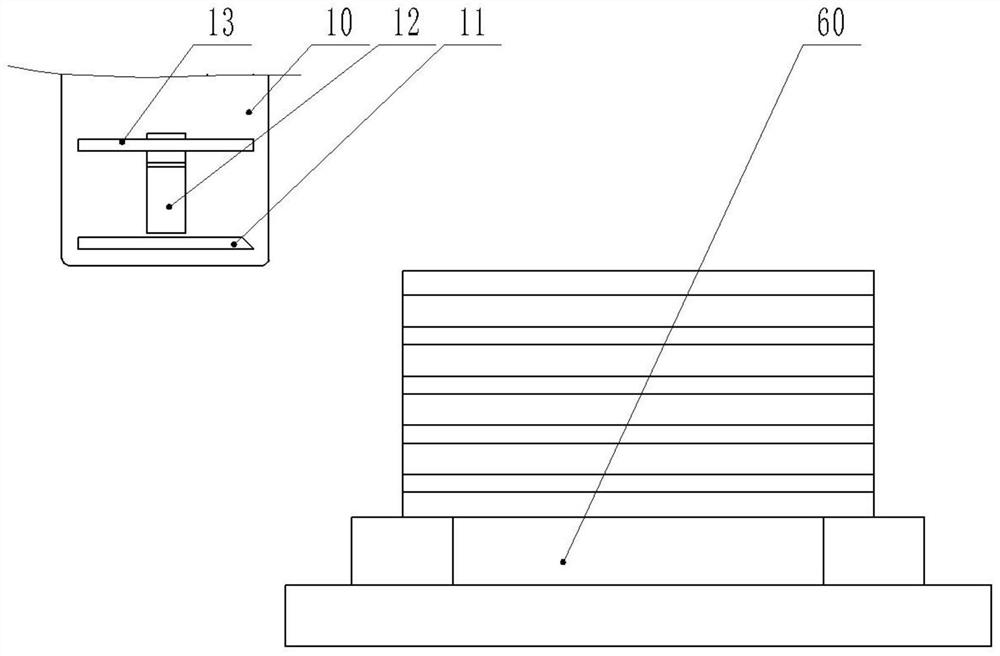

[0079] Such as image 3 , 4 As shown, the clamping mechanism 10 is installed on the lower end of the mounting base 40 , and the clamping mechanism 10 has: a bottom plate 11 , a chute 12 , a splint 13 , a resisting rod 14 , a stabilizing rod 15 , a telescopic structure 16 , and a knob 17 .

[0080] The bottom edge of the abutting rod 14 is an inclined slope structure, and the opposite surface of the bottom plate 11 and the board has an inclined guide surface structure.

[0081] The chute 12 is located above the base plate 11, the splint 13 ...

Embodiment 2

[0102] An automatic track changing device according to the thickness of the plate, such as Figure 11 As shown, clamping plate 13 is provided with pressing block 131, and pressing block 131 is positioned at the bottom of clamping plate 13, and pressing block 131 is connected with support spring 133 in clamping plate 13, and receiving block 132 is also provided in clamping plate 13, and receiving block 132 is positioned at The upper end of the tight block 131 has a gap between the pressing block 131 and the receiving block 132. Electromagnetic sheets are arranged on the opposite surfaces of the pressing block 131 and the receiving block 132. One of the electromagnetic sheets is connected to the power supply, and the other electromagnetic sheet is connected to the controller.

[0103] When clamping the plate, first the pressing block 131 under the splint 13 contacts the plate and shrinks under force. When the electromagnetic sheet on the pressing block 131 contacts the electromag...

Embodiment 3

[0106] A method for automatically changing track classification according to plate thickness, comprising the following steps:

[0107] Clamping, moving the plate to the bottom plate 11 of the clamping mechanism 10, and then starting the telescopic structure 16 to push the splint 13 connected to the contact rod 14 to move down and close to the bottom plate 11 to clamp the plate;

[0108] Triggering, during the downward movement of the splint 13, the contact rod 14 first pushes the rod head 171 on the knob 17, so that the rod head 171 rotates downward and squeezes the first trigger head 211 on the outer ring 21 of the track change mechanism 20, the first trigger The head 211 slides along the linear channel of the outer ring 21 to push the engagement rod 221 located in the limiting channel of the rotating shaft 22 to move. 222 disengages, and blocks another part of the arc-shaped groove 222 in the engaging rod 221 to limit the position of the engaging rod 221. After the engaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com