A cantilevered robotic arm

A robotic arm and cantilever technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of inability to meet, reduce the overturning application of the robotic arm, and the difficulty of conveying oblique materials with the robotic arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

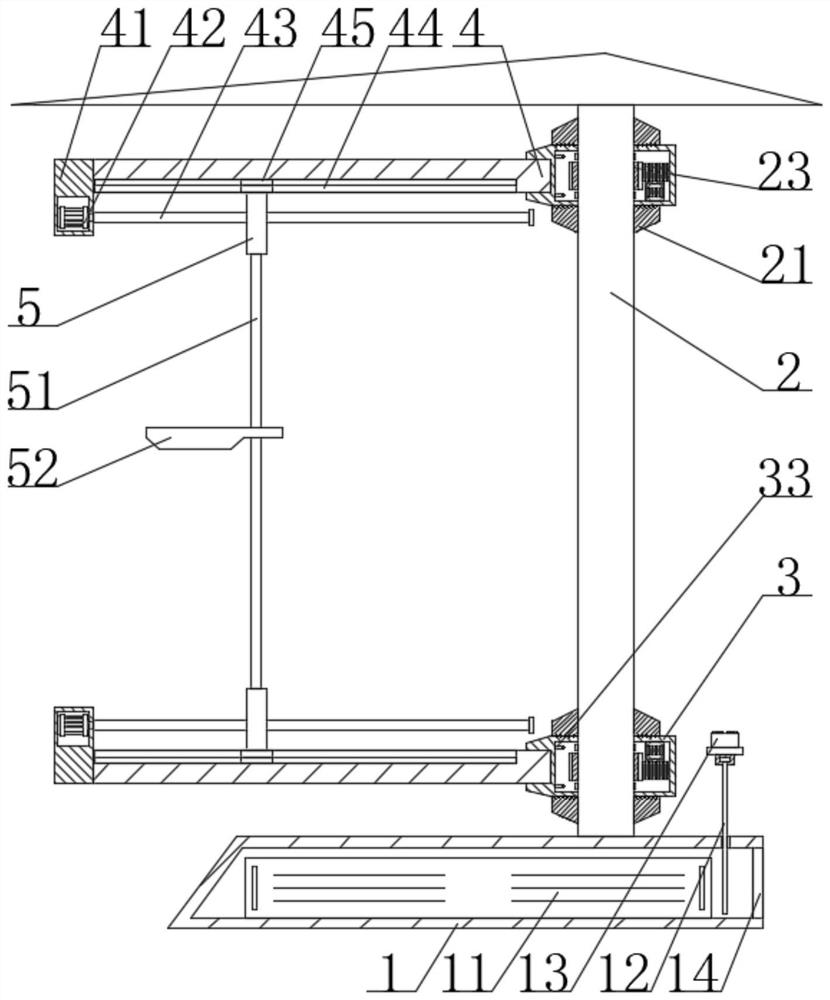

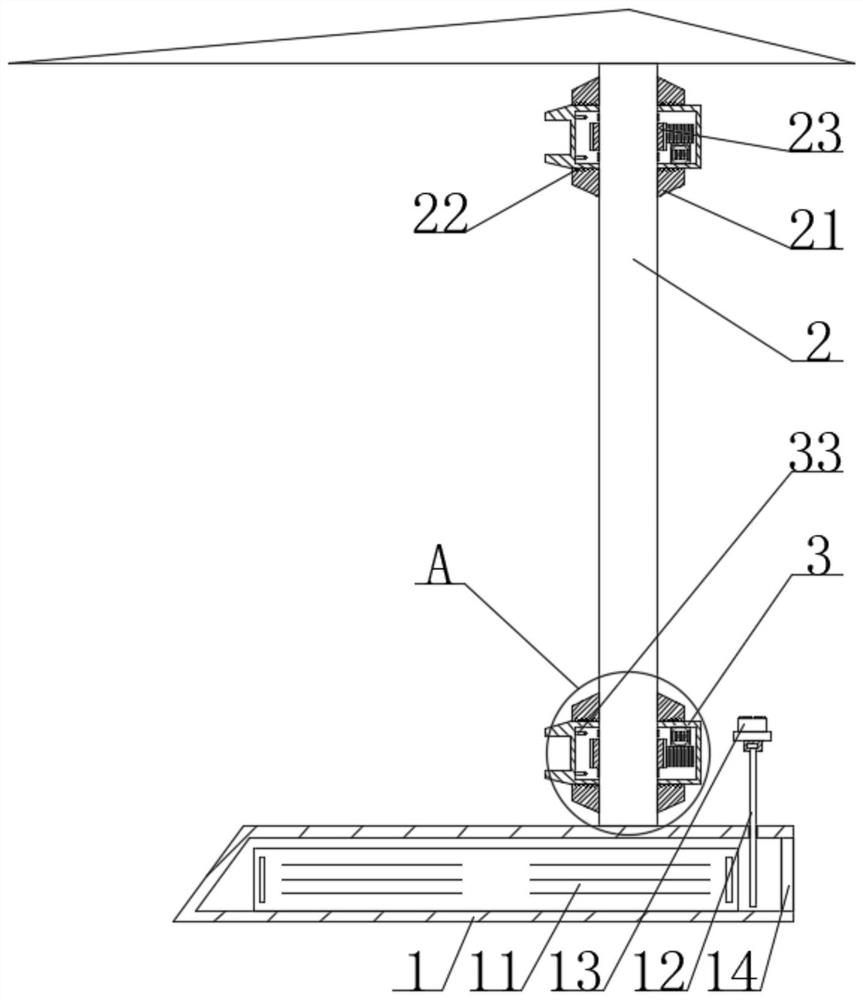

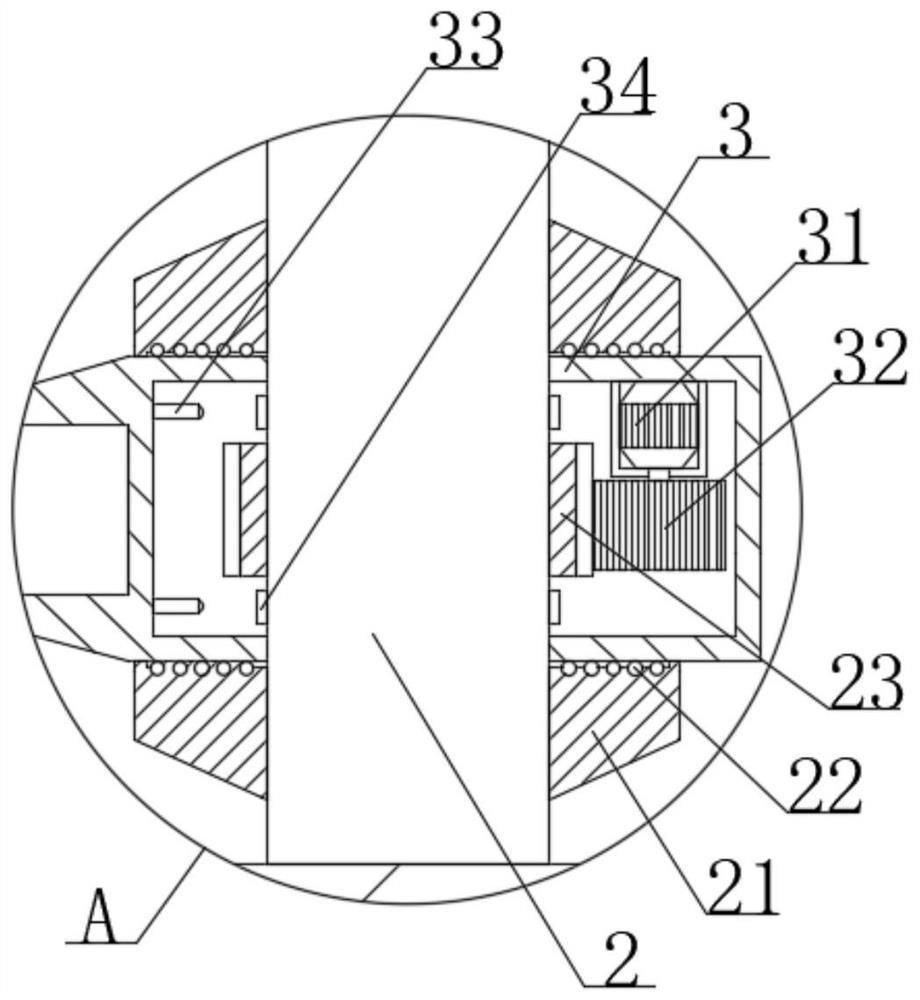

[0023] see Figure 1-5 , the present invention provides a technical solution: a cantilever mechanical arm, including a base 1, a support column 2 and a cantilever frame 4, the base 1 is in a right-angled trapezoidal structure, and the lower surface of the base 1 is provided with anti-slip lines, the base 1 The middle part of the lower surface of the inner wall is fixedly connected with a battery 11 by bolts, and the battery 11 can effectively provide electric energy. The middle part of the upper surface of the base 1 near the edge of one end is threadedly inserted with a screw rod 12, and the outer top of the screw rod 12 passes through a bearing The controller 13 is rotatably connected, and the position of the controller 13 on the base 1 can be effectively driven to lift through the screw rod 12, so as to facilitate the manipulation by users at different elevated positions. The middle part of one end of the base 1 is fixed and connected with a cover by bolts Plate 14, a seali...

Embodiment 2

[0025] see Figure 1-5, the present invention provides a technical solution: a cantilever mechanical arm, including a base 1, a support column 2 and a cantilever frame 4, the base 1 is in a right-angled trapezoidal structure, and the lower surface of the base 1 is provided with anti-slip lines, the base 1 The middle part of the lower surface of the inner wall is fixedly connected with a battery 11 by bolts, and the battery 11 can effectively provide electric energy. The middle part of the upper surface of the base 1 near the edge of one end is threadedly inserted with a screw rod 12, and the outer top of the screw rod 12 passes through a bearing The controller 13 is rotatably connected, and the position of the controller 13 on the base 1 can be effectively driven to lift through the screw rod 12, so as to facilitate the manipulation by users at different elevated positions. The middle part of one end of the base 1 is fixed and connected with a cover by bolts Plate 14, a sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com