Purification device and method for germanium tetrafluoride

A germanium tetrafluoride and condensation device technology, applied in the field of chemical equipment, can solve the problems of many germanium tetrafluoride impurities, difficult to purify due to special properties, etc., and achieve the effects of improving purity, stabilizing temperature deviation and expanding condensation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

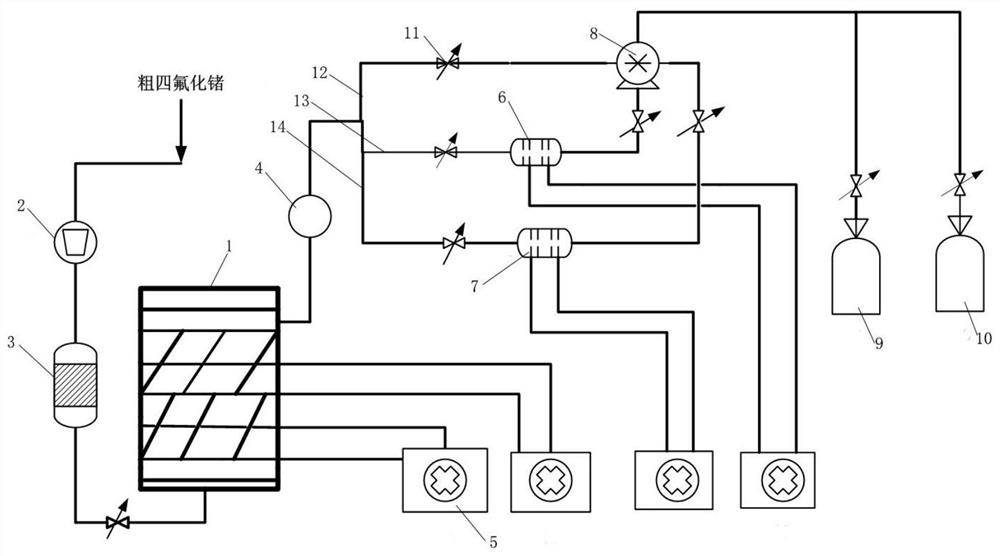

[0037] Such as Figure 1-4 As shown, a purification device for germanium tetrafluoride includes a gas supply device, a rectification tower 1, a condensation device 5, a transfer device 8 and a storage device, and the storage device is a waste gas collection bottle 9 and a germanium tetrafluoride collection bottle 10, and the pipeline connecting the collection bottle is provided with a valve 11, the gas supply device includes a flow meter 2, a 4A molecular sieve 3 and the valve are connected to the bottom of the rectification tower 1 through pipelines in turn, and the condensing device 5 is a refrigeration device, which can be an existing A variety of refrigerators.

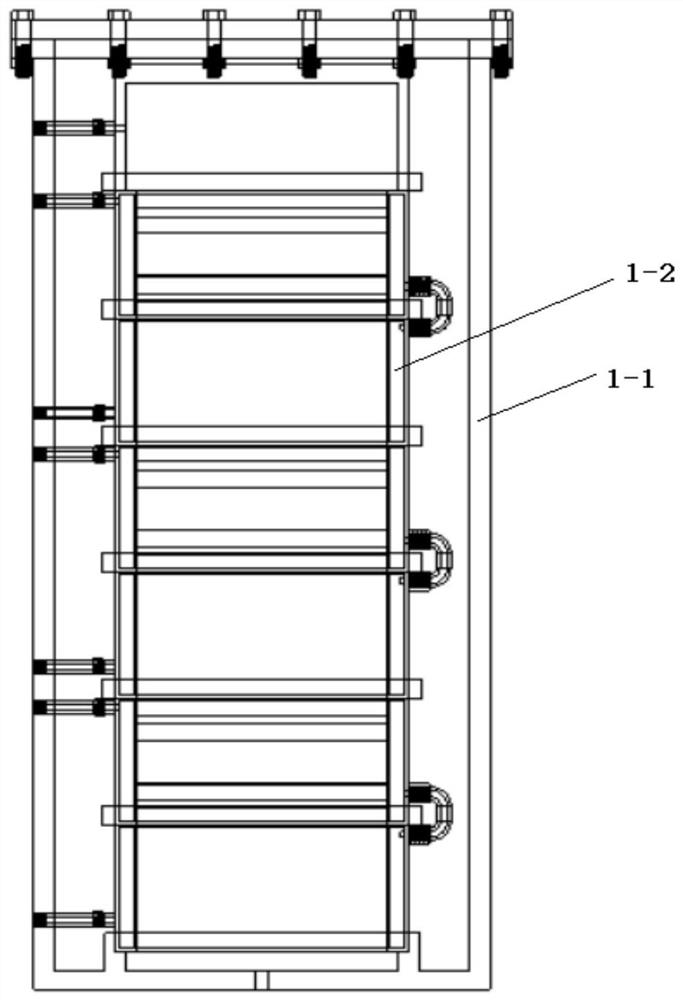

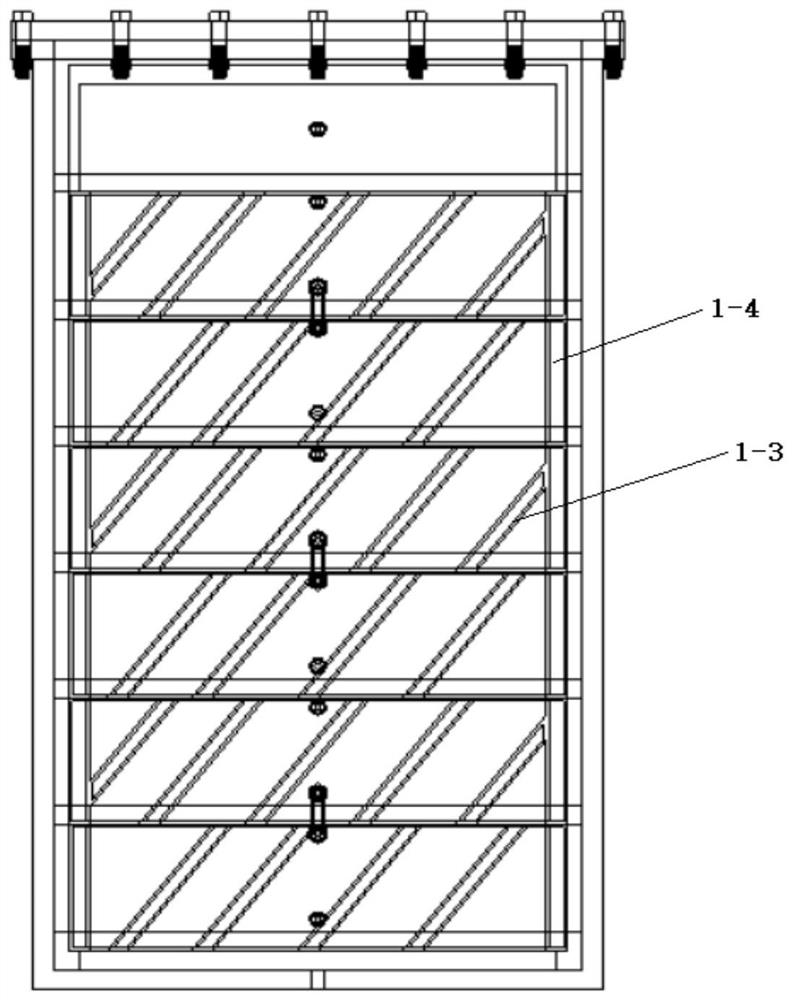

[0038] The rectification column 1 includes a shell 1-1 and several layers of tower frames 1-2. A rectangular tower frame 1-4 is arranged in the tower frame. The tower frame and the tower frame are opened at the top and bottom. Angled trays 1-3, each layer of tower frames 1-2 are connected to the inlet / outlet pipe...

Embodiment 2

[0043] Purification device is connected according to the order in embodiment 1, wherein the tower frame in the rectifying tower is 6 layers, externally connects three condensing devices, the long 50cm wide 40cm high 30cm of tower frame body, used conventional instrument all can be purchased from the market, The model of the condensing unit may be K-5AHGT. The specific purification method using this structure is as follows:

[0044] (1) Open all valves except the gas supply device, turn on the air pump, evacuate the entire purification device, and then close all valves;

[0045] (2) Turn on the condensing device connected to the rectifying tower and the first condensing pipe. The condensing device feeds the condensing agent to the rectifying tower. The temperature is -10°C; the temperature of the first condensing pipe is -50°C, then open the valve of the gas supply device, the front and rear valves of the first condensing pipe, and the front valve of the exhaust gas collection...

Embodiment 3

[0051] Purification device is connected according to the order in embodiment 1, wherein the tower frame in the rectifying tower is 6 layers, externally connects three condensing devices, the long 50cm wide 40cm high 30cm of tower frame body, used conventional instrument all can be purchased from the market, The model of the condensing unit may be K-5AHGT. The specific purification method using this structure is as follows:

[0052] (1) Open all valves except the gas supply device, turn on the air pump, evacuate the entire purification device, and then close all valves;

[0053] (2) Turn on the condensing device connected to the rectifying tower and the first condensing pipe, the condensing agent input from the condensing device to the rectifying tower, the temperature of the condensing agent input at the top of the tower frame is -40°C, the middle temperature is -35°C, the bottom Temperature -5°C; the temperature of the first condensing pipe is -50°C, then open the valve of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com