Rail transport multi-purpose telescopic wagon

A railway transportation and multi-purpose technology, applied in the field of trucks, can solve the problems such as the inability to adjust the storage space of trucks, the unbalanced number of loading and unloading vehicles at the station, and the reduction of the running rate of empty vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

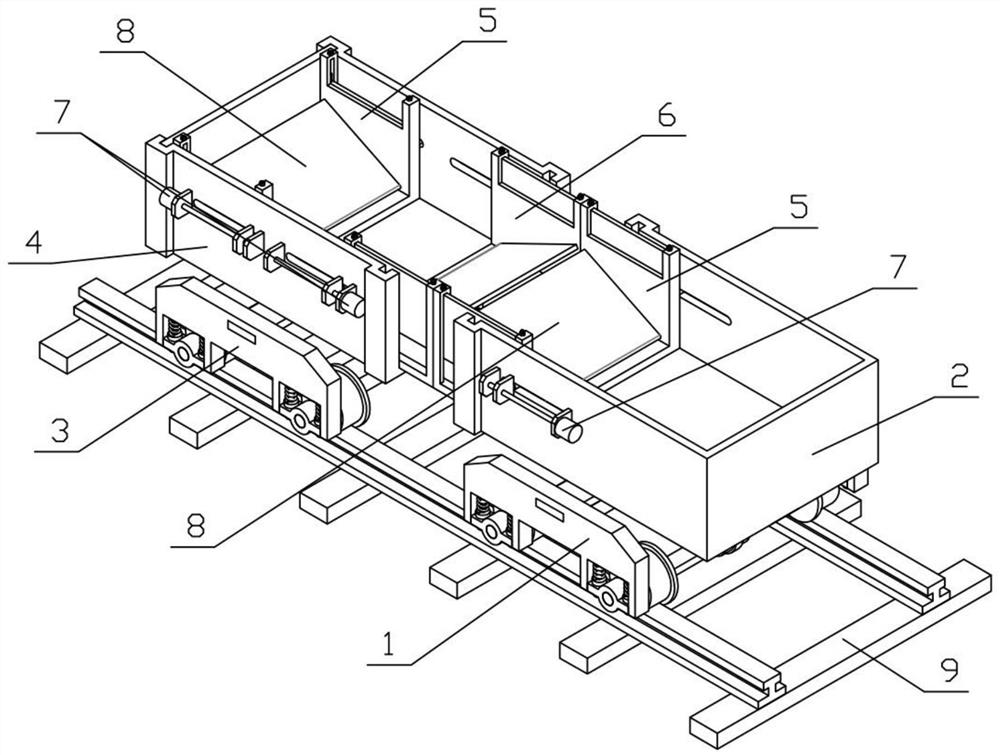

[0035] Combine below Figures 1 to 12 Illustrate this embodiment, the railway transport multi-purpose telescoping freight car, comprises motion mechanism 1, cargo box I2, driven mechanism 3, cargo box II4, connection mechanism I5, connection mechanism II6 and traverse motor 7, the motion mechanism 1 is fixedly connected with shipping box I2, the driven mechanism 3 is fixedly connected with shipping box II4, the rear end of shipping box I2 is slidably connected with connecting mechanism I5, and shipping box I2 is fixedly connected with traverse motor 7 , the connecting mechanism Ⅰ5 is connected to the output shaft of the traversing motor 7 through threads, the front and rear ends of the cargo box Ⅱ4 are respectively slidingly connected with the connecting mechanism Ⅱ6 and the connecting mechanism Ⅰ5, and the cargo box Ⅱ4 is fixedly connected with two traversing motors 7. The connection mechanism II6 and the connection mechanism I5 are connected to the output shafts of the two t...

specific Embodiment approach 2

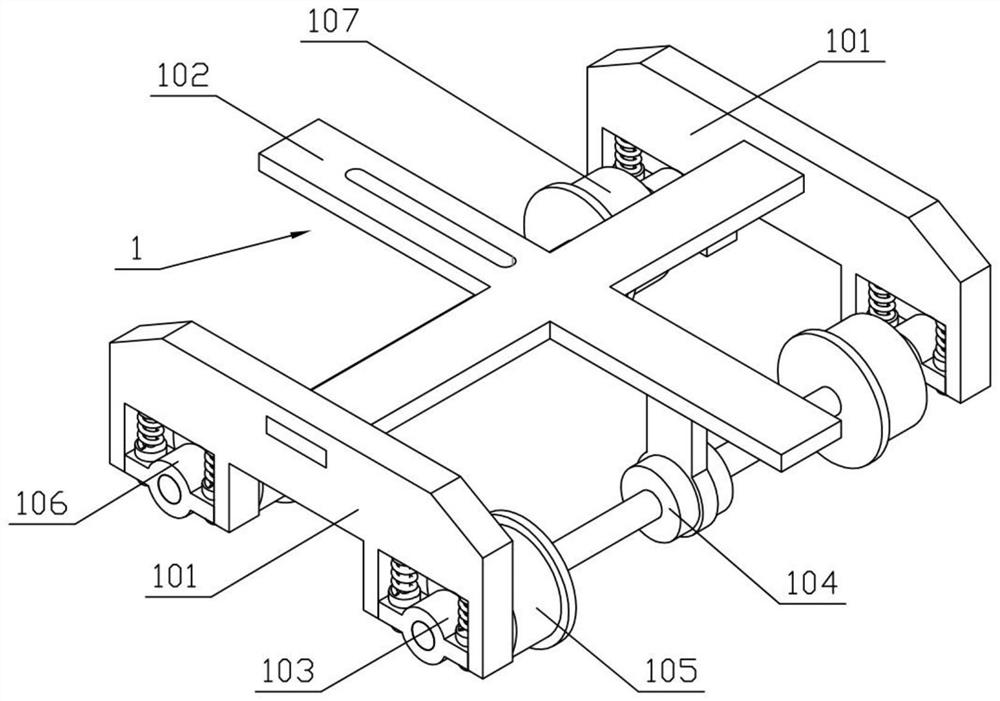

[0037] Combine below Figures 1 to 12 Describe this embodiment, this embodiment will further explain the first embodiment, the motion mechanism 1 includes a motion bracket 101, a connecting bracket I 102, a bearing seat I 103, a motion motor 104, a motion wheel I 105, a bearing block II 106 and a motion wheel II 107, and the motion There are two brackets 101, a connecting bracket I102 is fixedly connected between the two moving brackets 101, the front ends of the two moving brackets 101 are slidingly connected with a bearing seat I103, and a compression spring is fixedly connected between the bearing seat I103 and the moving bracket 101 Ⅰ. The motion motor 104 is fixedly connected to the connection bracket I 102, and the motion wheel I 105 is rotatably connected between the two bearing housings I 103. The motion wheel I 105 is connected to the output shaft of the motion motor 104 through transmission, and the rear ends of the two motion brackets 101 all slide A bearing seat II...

specific Embodiment approach 3

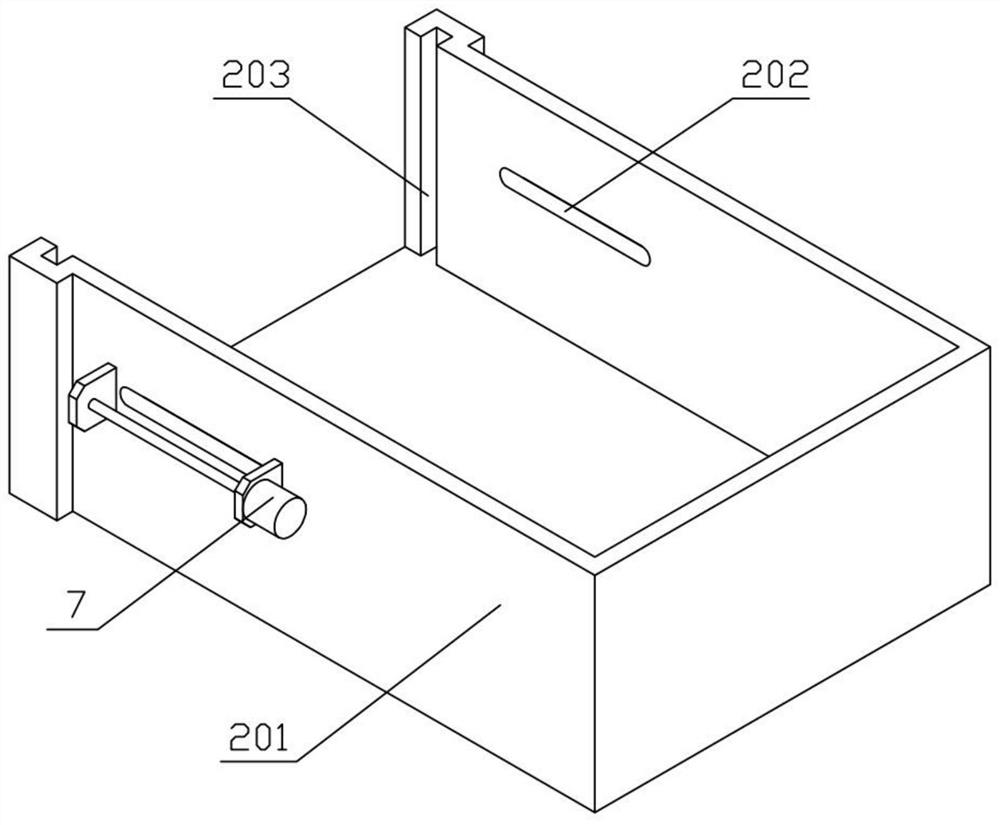

[0039] Combine below Figures 1 to 12 This embodiment will be described. This embodiment will further explain the second embodiment. The cargo box I2 includes a cargo box body I201, a sliding waist hole I202 and an installation slot I203. The waist hole I202 and the rear end of the cargo box I201 are provided with an installation slot I203, the cargo box I201 is fixedly connected to the connecting bracket I102, and the cargo box I201 is fixedly connected to the traverse motor 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com