Tunnel piston pressure relief device

A pressure relief device and piston technology, applied in mining devices, tunnel systems, roads, etc., can solve problems such as train shaking, safety accidents, affecting train running, etc., and achieve the effect of reducing wind speed and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

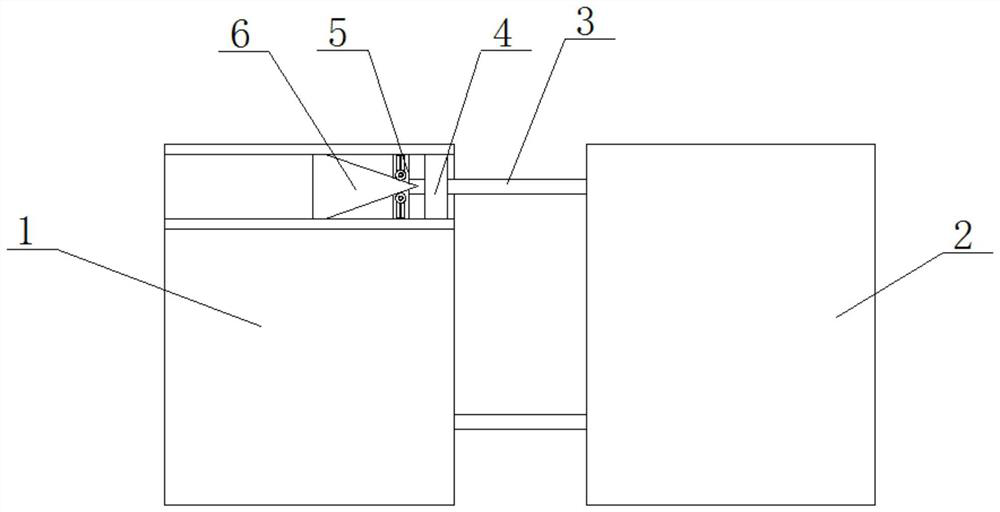

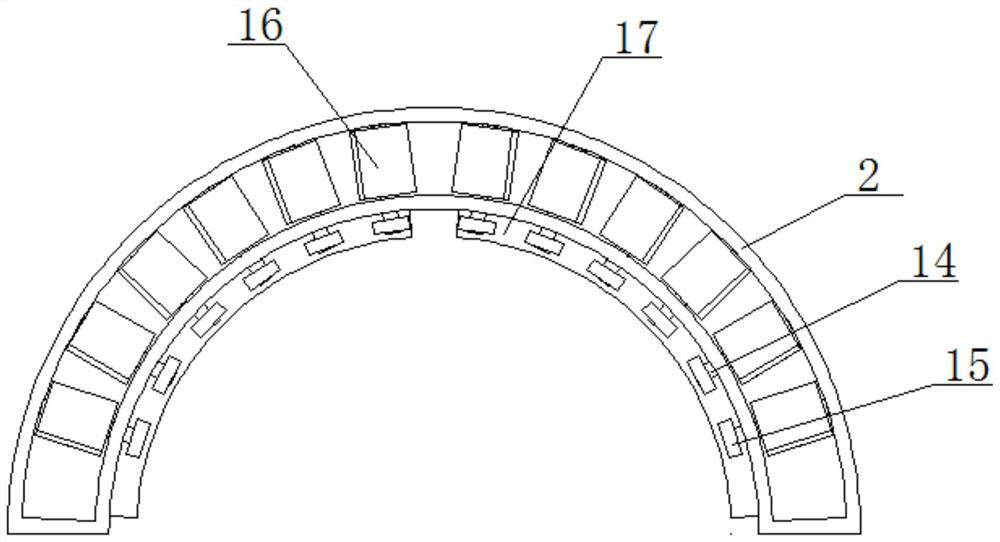

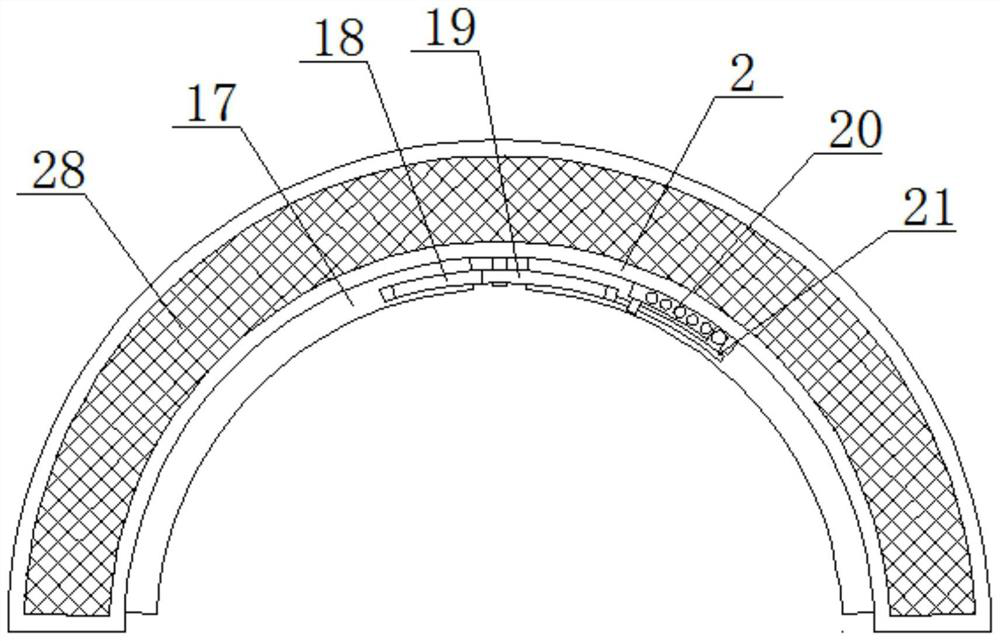

[0030] Such as Figure 1-6 The shown tunnel piston pressure relief device includes a support ring 1, a plurality of support rods 3 are slidingly connected at equal intervals in the support ring 1, and one end of the plurality of support rods 3 extends to the outside of the support ring 1 and is fixedly installed There is the same buffer ring 2, a plurality of support shafts 14 are symmetrically rotated and connected in the buffer ring 2, and the bottom ends of the plurality of support shafts 14 all extend to the bottom of the buffer ring 2, and the bottom of the buffer ring 2 is symmetrically slidably connected with two Transmission rack 17, two transmission racks 17 are connected in transmission, the bottom end of the support shaft 14 is fixedly equipped with a rotating gear 15, and the transmission rack 17 is respectively meshed with a plurality of rotating gears 15 on the same sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com