Wind power generation equipment

A technology of wind power generation equipment and wind wheel, which is applied to wind power generation, wind turbines, wind turbines in the same direction as the wind, etc., can solve the problems of inability to rotate, wear, and jam the equipment, and achieve the effect of prolonged use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

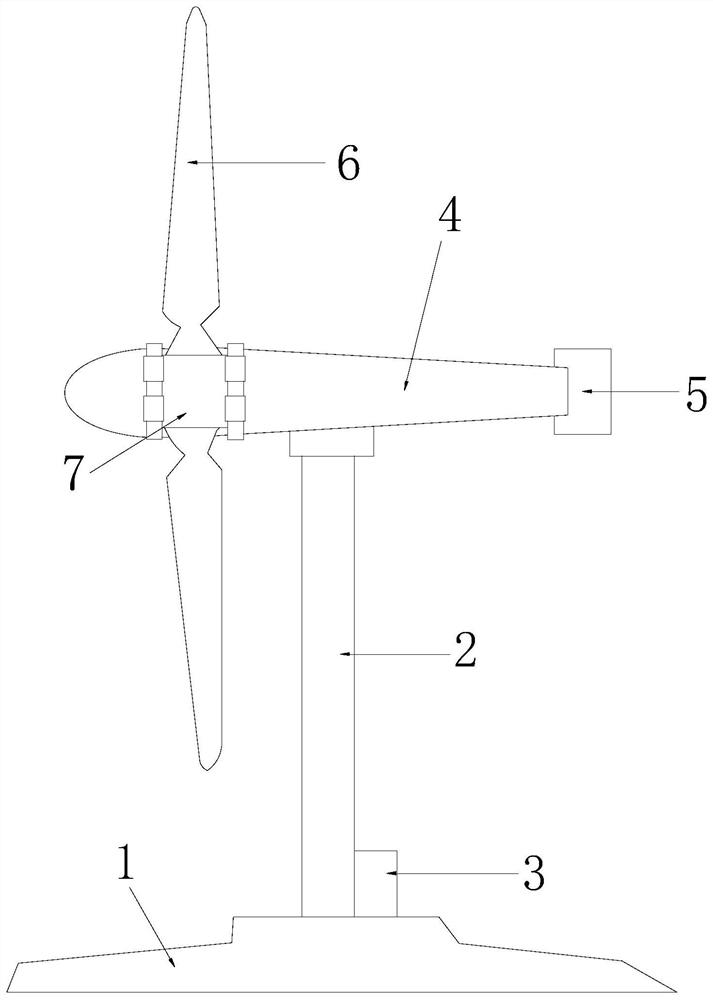

[0028] Such as Figure 1-Figure 6 As shown, the present invention provides a kind of technical scheme of wind power generation equipment:

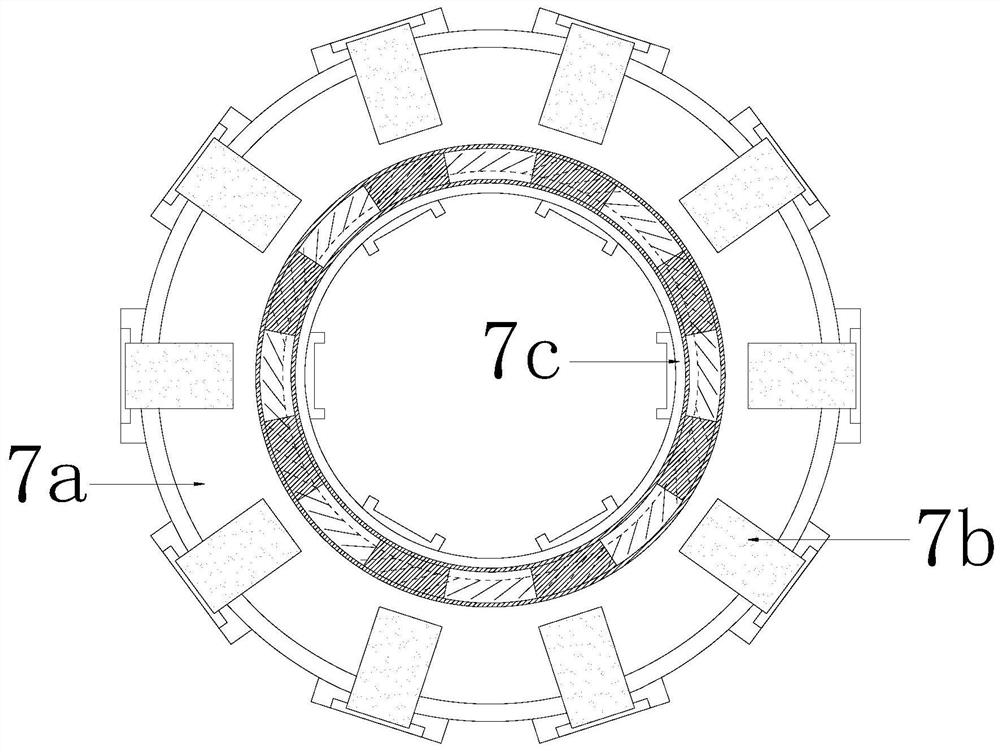

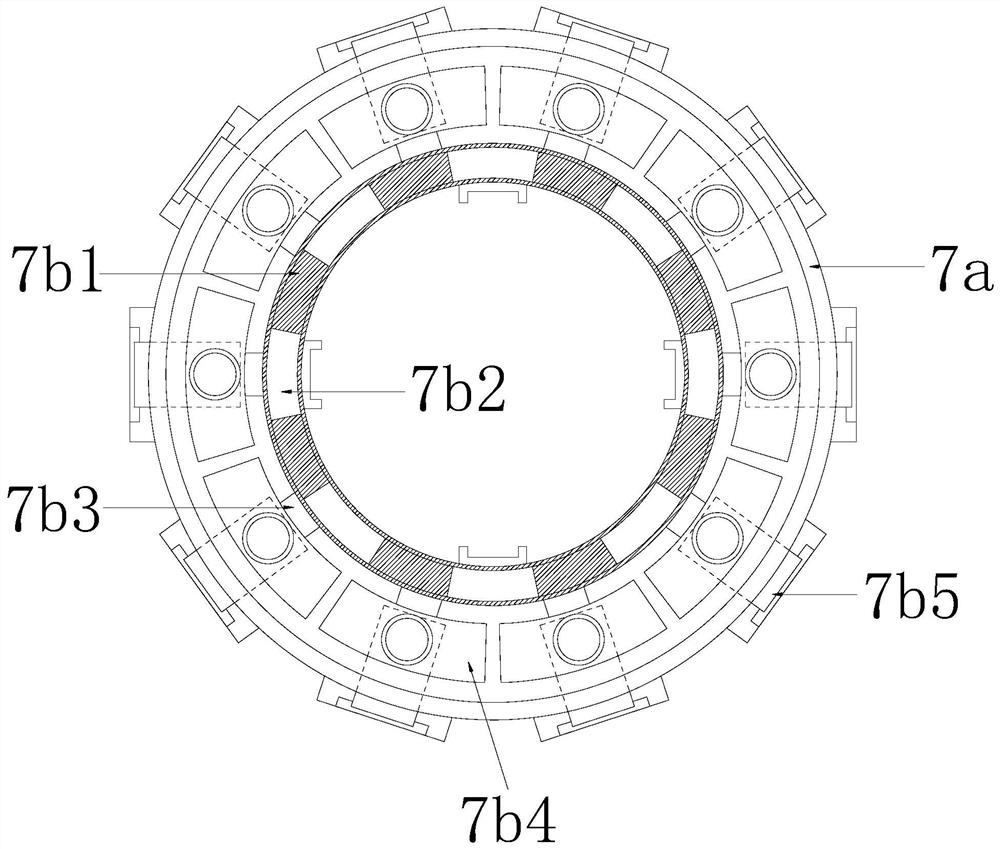

[0029] Such as Figure 1-Figure 2 As shown, a wind power generation equipment, its structure includes a base 1, a tower body 2, a power supply box 3, a main body 4, a tail body 5, a wind wheel 6, and a protective device 7, and the tower body 2 is installed on the base 1 on the upper surface, the power supply box 3 is matched with the lower part of the tower body 2, the main body 4 is installed on the top of the tower body 2, the tail body 5 is arranged on the rear surface of the main body 4 and fastened together, the wind wheel 6 Installed on the front end of the main body 4, the auxiliary protection device 7 is installed on the outer surface of the wind wheel 6. The auxiliary protection device 7 includes a mounting sleeve 7a, a restraining mechanism 7b, and an auxiliary rotation structure 7c. The restraining mechanism 7b is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com