Shielded wire insulation rapid binding device and method

A technology for insulating wrapping and shielding wires, which is applied in circuit/collector parts, electrical components, circuits, etc., to achieve the effects of low manufacturing cost, improved production efficiency, and reduced repetitive labor time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

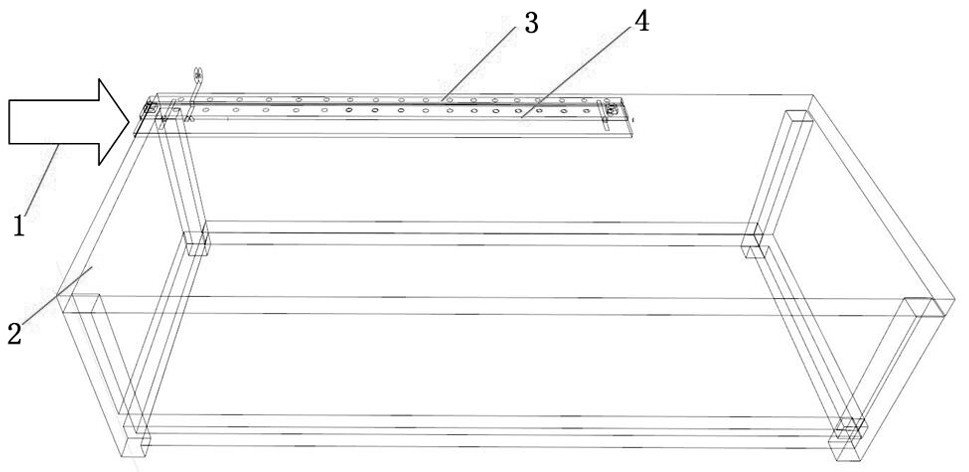

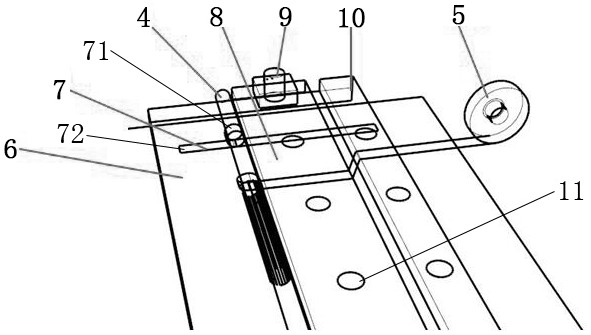

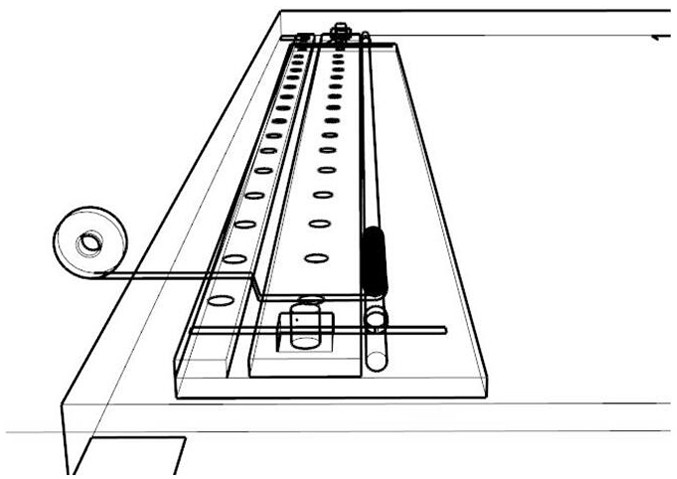

[0024] A shielded wire insulation fast bandaging device, comprising a motor 1, an operating table 2 and a shielded wire fixing device 3, the motor 1 is arranged on one side of the operating table 2, and the shielding wire fixing device 3 is arranged on the operating table 2; the shielding wire is fixed The device includes crepe paper 5, support frame 6, snap ring 7, compression frame 8, fixed screw rod 9 and guide frame 10, support frame 6 is horizontally arranged on the operation platform 2, and support frame 6 is provided with snap ring 7, compression frame 8 and guide frame 10, the number of snap rings is multiple, copper rod shielding wire 4 is clamped in the snap ring, copper rod shielding wire 4 ends are fixedly connected with the motor, copper rod shielding wire 4, pressing frame 8 and The guide frame 10 is arranged in parallel, the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com