Method for rapidly generating a shape detection report

A shape detection and reporting technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of wasting effective online working time of detection instruments, inflexible quality inspection report generation methods, and reducing the work efficiency of operators. , to achieve the effect of increasing effective online working time, reducing manual copying of data, and reducing duplication of labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

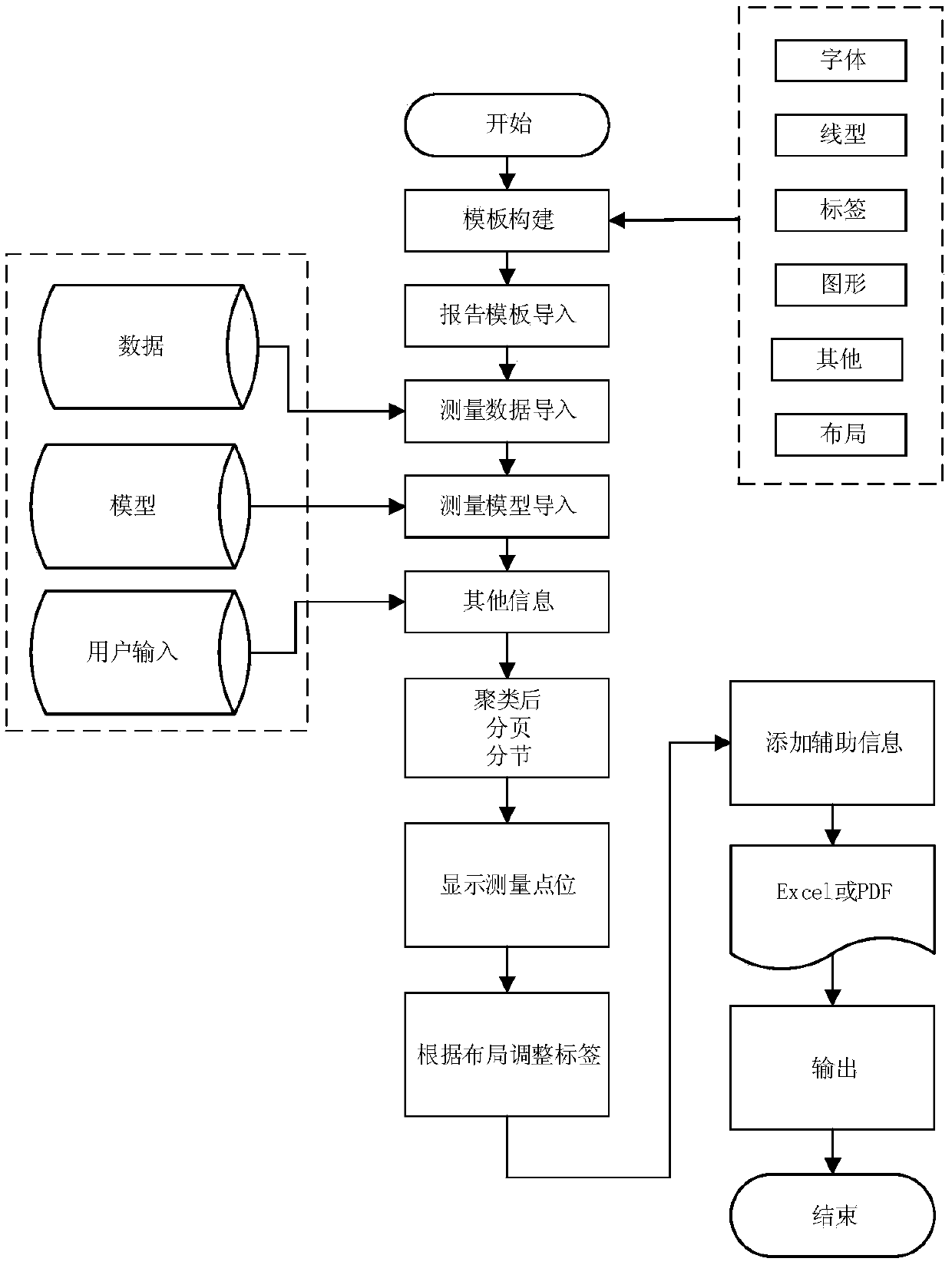

[0037] A rapid method for generating shape inspection reports, such as Figure 1 The flow shown, the specific steps are as follows:

[0038] Step 1: Set the report template according to the actual requirements of the parts to be tested

[0039] Build font libraries, label libraries, graphics libraries, etc.

[0040] The font library is an important part of the report display. Since Chinese characters are different from Western fonts, the character set is very large. The most commonly used font library standard is the TrueType font library, which is also the only font standard used by the Windows operating system. Due to the individual requirements of the enterprise, it is often necessary to change the display format of the label for different parts under test, including requirements such as font type, font size, and background c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com