Automatic rocket tube section assembling system based on planar 3-PRR parallel structures

A configuration and parallel technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low reliability of assembly quality, limited attitude adjustment ability, and large assembly workload, so as to improve assembly efficiency and assembly. Quality reliability, avoiding the effect of forced assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

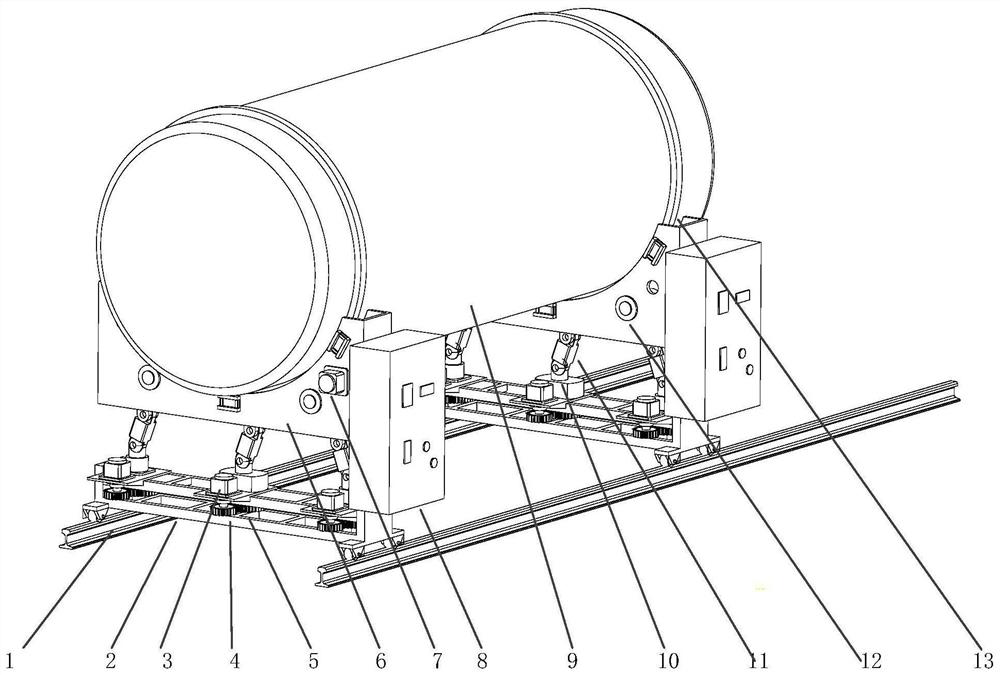

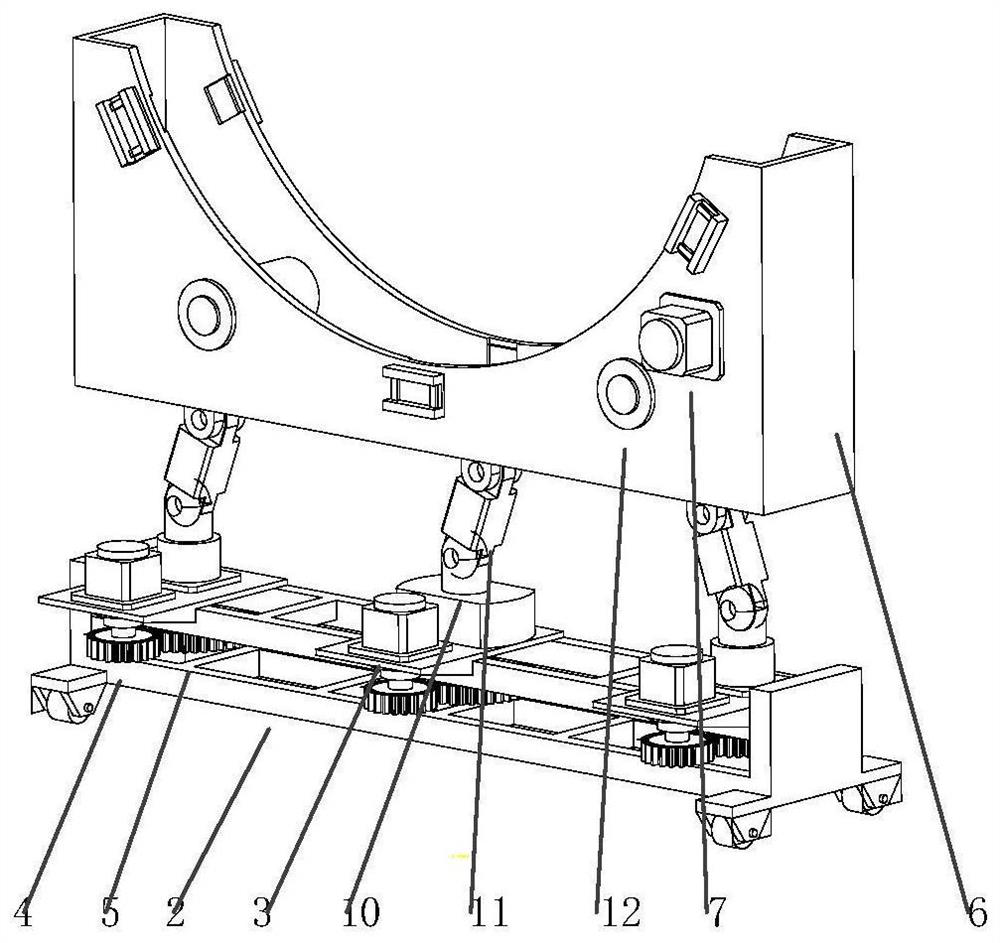

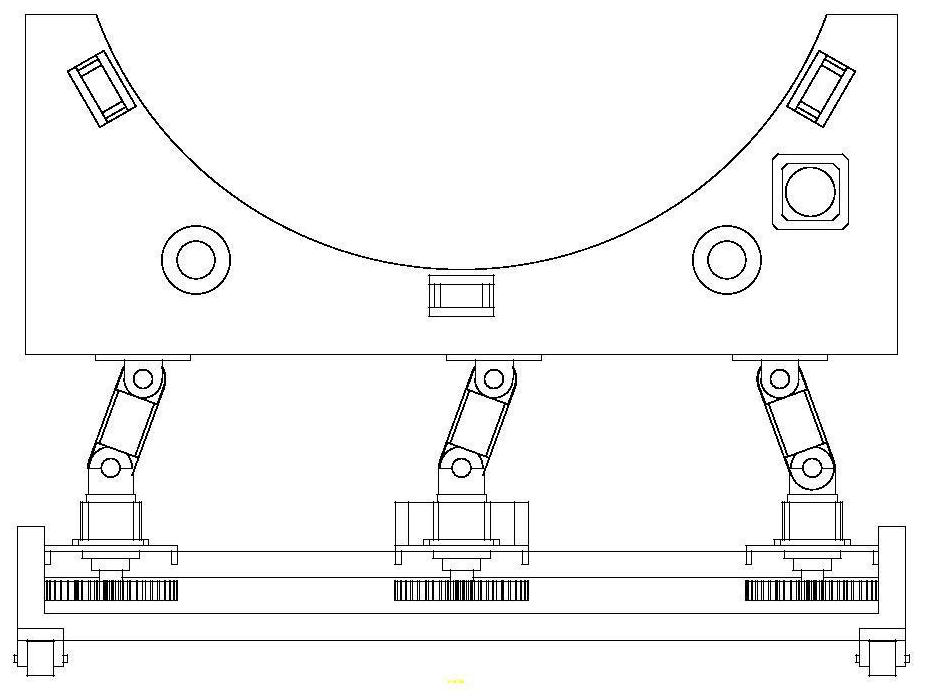

[0019] The purpose of the present invention is to provide an automatic assembly system for rocket launcher sections based on the plane 3-PRR parallel configuration, which is characterized in that it includes: track 1, vehicle frame chassis assembly 2, control cabinet 8, rocket body arc bracket 6, Arrow body hoop 13, wherein, the vehicle frame chassis assembly 2 is placed vertically with the track, pulleys are arranged at both ends of the vehicle frame chassis assembly, placed on the track, and slide along the track; the vehicle frame chassis assembly 2, along the chassis assembly of the frame, that is, along the direction perpendicular to the track, there are 3 sets of PRR configurations, wherein the PRR configurations include: sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com