A sandwich-like pn junction and its precise construction method

A sandwich and PN junction technology, applied in the field of PN junctions, can solve the problems of lack of strategy models and achieve the effect of improving photoelectrochemical performance and precise controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

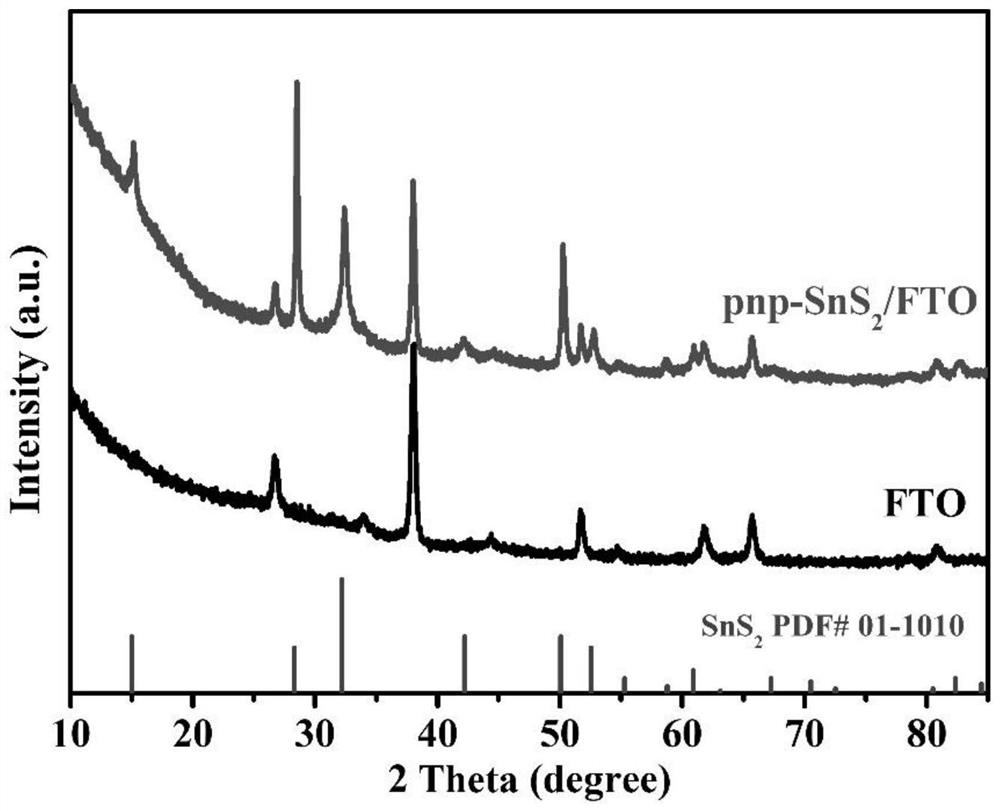

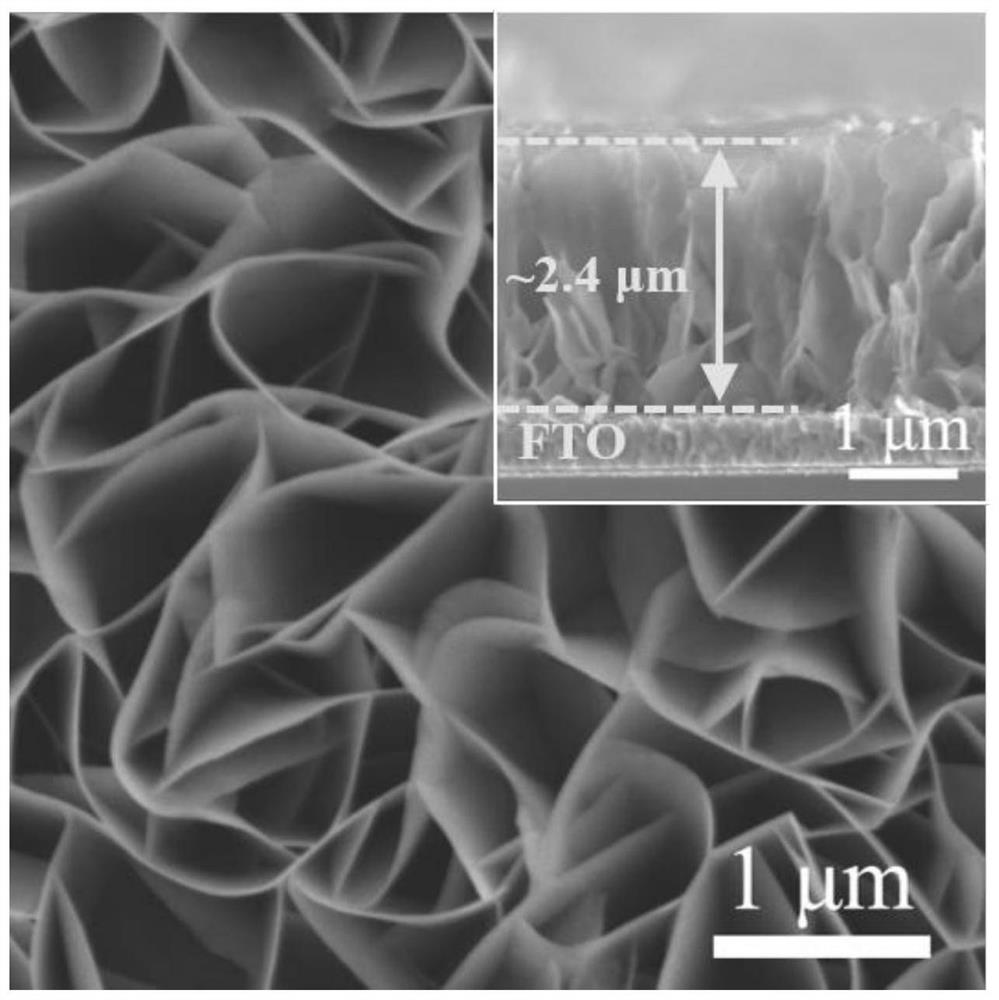

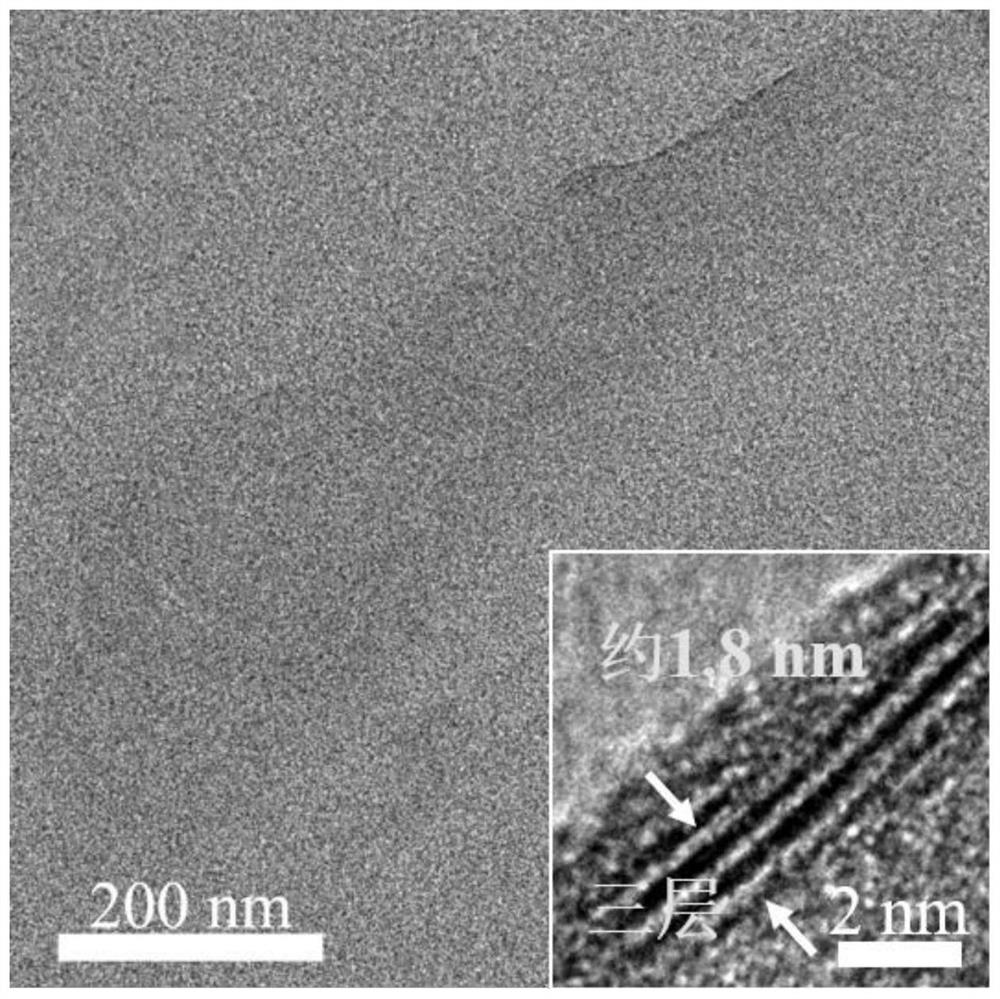

[0064] SnO doped with fluorine 2 Conductive glass (conductive glass FTO) was continuously sonicated in acetone, ethanol and deionized water for 30 min each, dried and used for later use. Put tin sulfate and thiourea into a beaker with an atomic ratio of Sn:S=1:2, add 0.1 mmol ammonia water and an appropriate amount of deionized water, and fully stir to obtain a reaction solution. Then, put the dry conductive glass FTO into the polytetrafluoroethylene liner, and slowly drop the reaction droplets into the liner. The volume ratio of the conductive glass FTO to the reaction solution is 1:2, and the reaction solution does not completely submerge the conductive glass. Put the polytetrafluoroethylene liner into the autoclave, then put the autoclave into the oven, and react at 100°C for 40h. After the reaction was completed, the temperature was naturally cooled to room temperature. The reaction kettle was opened, a thin film was formed on the conductive glass FTO, the conductive gla...

Embodiment 2

[0067] SnO doped with fluorine 2 Conductive glass (conductive glass FTO) was continuously sonicated in acetone, ethanol and deionized water for 30 min each, dried and used for later use. Put tin chloride and thioacetamide into a beaker with an atomic ratio of Sn:S=1:2, add 10 mmol of ammonium sulfate and an appropriate amount of isopropanol, and fully stir to obtain a reaction solution. Then, put the dried conductive glass FTO into the polytetrafluoroethylene liner, and slowly drop the reaction drop into the liner. The volume ratio of the conductive glass FTO to the reaction solution is 1:10, and the reaction solution does not completely submerge the conductive glass. Put the polytetrafluoroethylene liner into the autoclave, then put the autoclave into the oven, and react at 200°C for 2 hours. After the reaction was completed, the temperature was naturally cooled to room temperature. Open the reactor, a thin film is formed on the conductive glass FTO, take out the conductive...

Embodiment 3

[0070] SnO doped with fluorine 2 Conductive glass (conductive glass FTO) was continuously sonicated in acetone, ethanol and deionized water for 30 min each, dried and used for later use. Put tin oxalate and sodium thiosulfate into a beaker with an atomic ratio Sn:S=1:2, add 5 mmol of tetramethylammonium and an appropriate amount of ethanol, and stir well to obtain a reaction solution. Then, put the dry conductive glass FTO into the polytetrafluoroethylene liner, and slowly drop the reaction drop into the liner. The volume ratio of the conductive glass FTO to the reaction solution is 1:6, and the reaction solution does not completely submerge the conductive glass. Put the polytetrafluoroethylene liner into the autoclave, then put the autoclave into the oven, and react at 150°C for 20h. After the reaction was completed, the temperature was naturally cooled to room temperature. Open the reaction kettle, a thin film is formed on the conductive glass FTO, take out the conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com