A vibrating wire three-dimensional stress sensor for deep hole stress measurement

A technology of three-dimensional stress and ground stress, which is applied in the measurement of the frequency change force of the stressed vibrating element, the measurement of the force component, etc., can solve the problems that the tensile stress of the rock and soil cannot be realized, cannot be implemented, and the implementation is troublesome, etc. problem, to achieve scientific rock and soil stress measurement, ensure waterproof effect, and fix firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings.

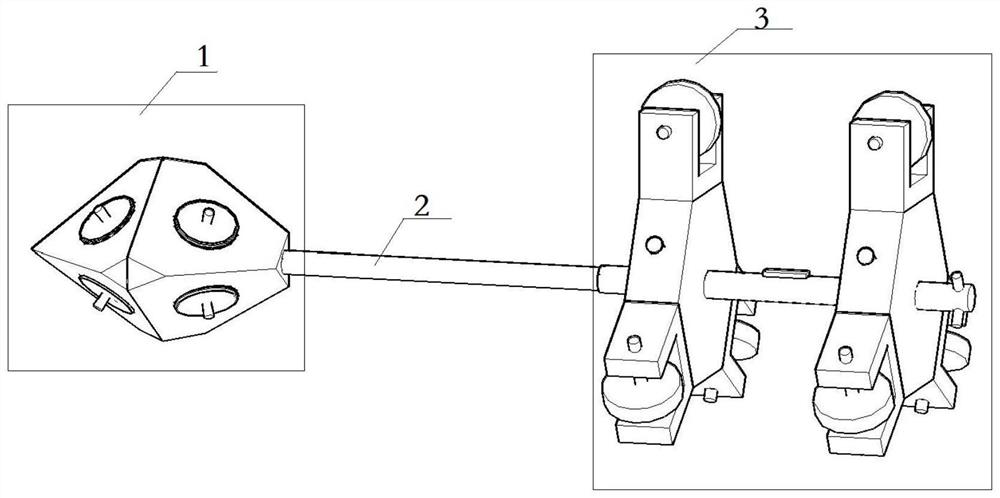

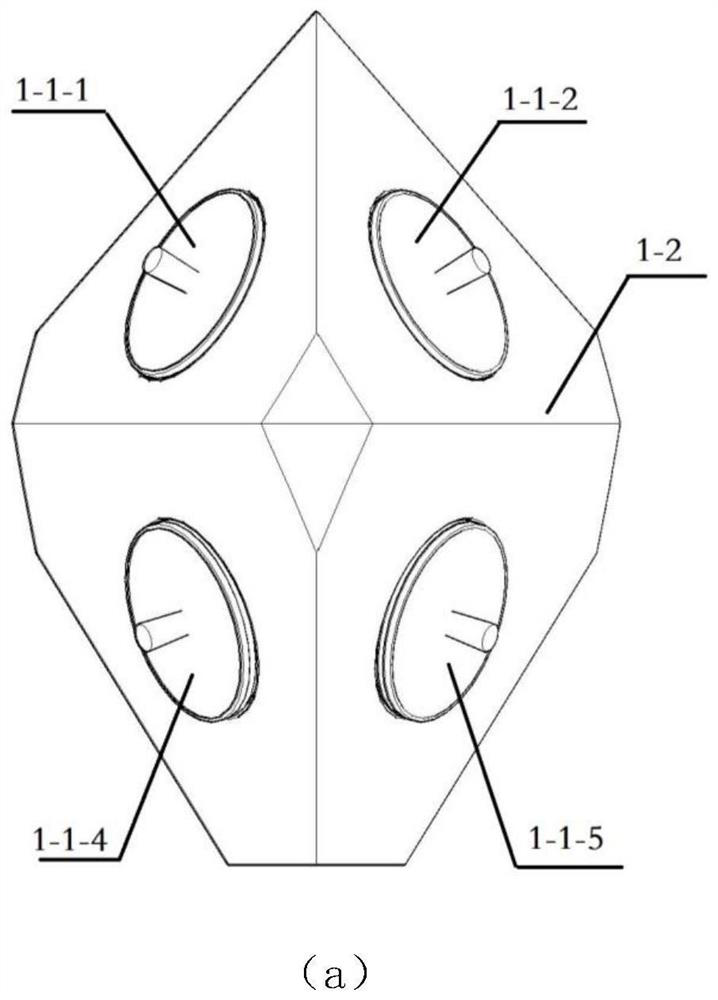

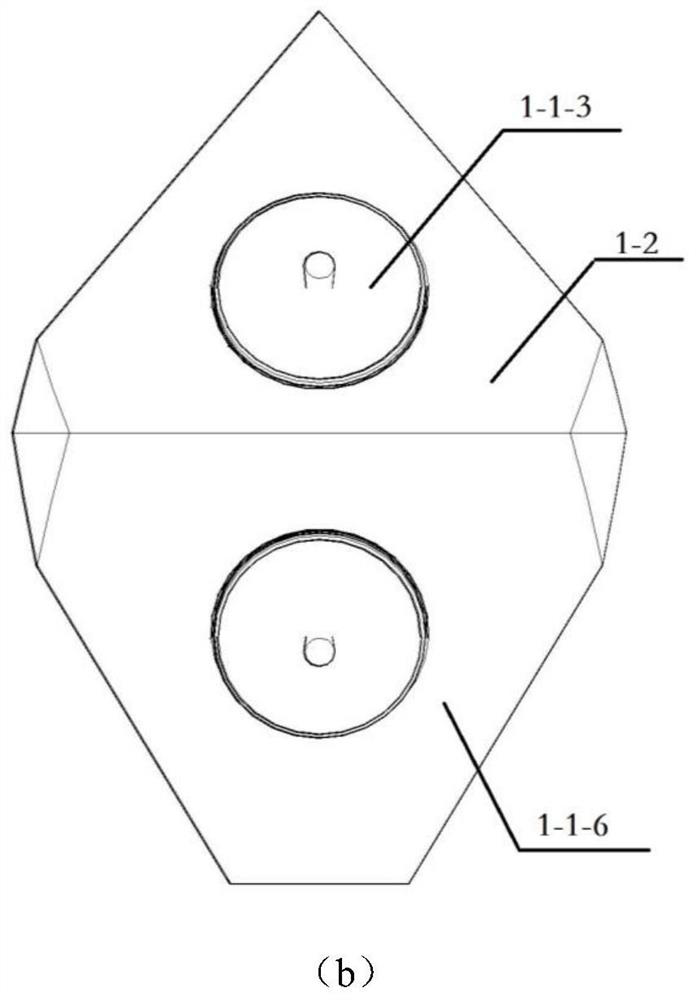

[0037] A vibrating wire three-dimensional stress sensor for deep hole stress measurement, comprising a support body 1-2, the support body 1-2 is provided with installation grooves, and sensing units are arranged in the installation grooves,

[0038] The sensing unit includes a pressure head C-2, one end of the pressure head C-2 is provided with a slider C-1, and the other end is provided with a force transmission head C2-3, and the force transmission head C2-3 is connected with the elastic beam C-5-1. The middle part of the side is connected, and the other middle part of the elastic beam C-5-1 is provided with an induction coil C-5-3 and two ends are provided with clamps C-5-2, and the two clamps C-5-2 are respectively passed through the steel String C-5-4 is connected to induction coil C-5-3.

[0039] The slider C-1 transmits the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com