Marble slab continuous and uniform grinding equipment and method

A marble slab and uniform technology, which is applied in the direction of grinding/polishing equipment, grinding devices, grinding machine tools, etc., can solve the problems that dust particles cannot be effectively treated, and marble slabs cannot be covered and ground, so as to prevent dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028]Example 1

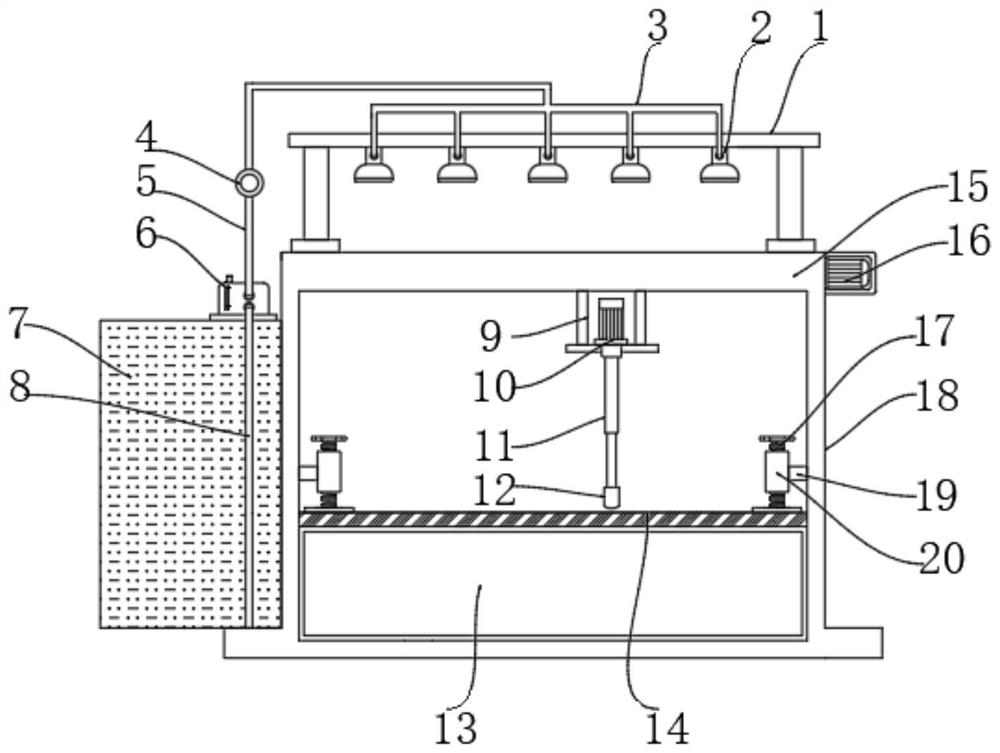

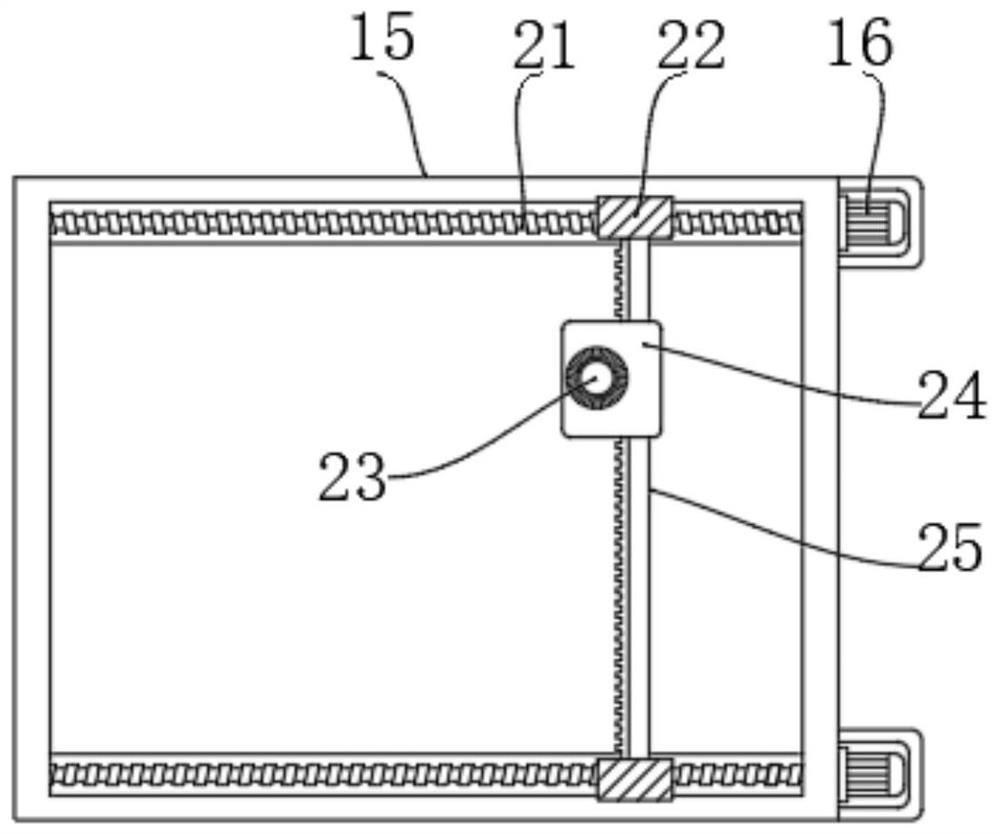

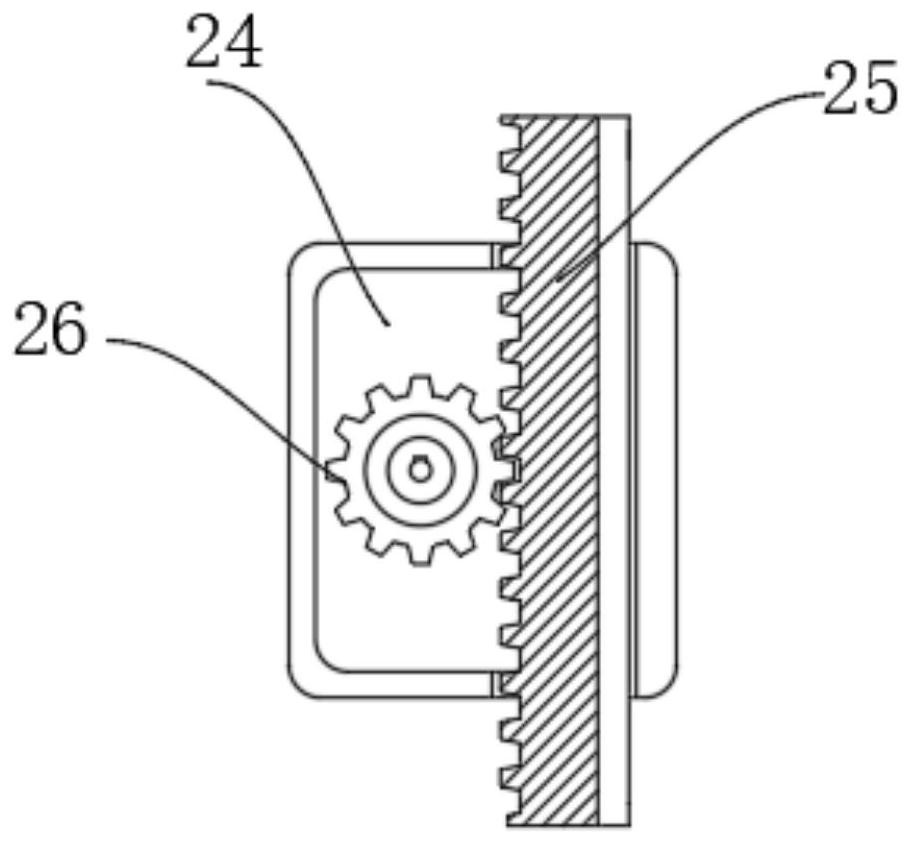

[0029]Such asFigure 1-4As shown, an embodiment provided by the present invention: a continuous and uniform grinding equipment for marble slabs, including a working frame 15, a fixed frame 1 is installed on the top of the working frame 15, and cooling water is installed on the fixed frame 1 Spray head 2, a cooling water storage tank 7 is installed on one side of the working frame 15. The inside of the cooling water storage tank 7 is connected with a driving water pump 6 through a water guide tube 8, and one end of the driving water pump 6 is installed with a water supply main pipe 5. A servo motor 16 is installed on one side of the frame 15. The front end of the servo motor 16 is rotatably connected with the screw main body 21 through a rotating shaft. A sliding block 22 is installed on the surface of the screw main body 21, and a fixed rack 25 is installed between the sliding blocks 22. A control box 24 is installed on the fixed rack 25, a movable gear 26 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com