Spliced wallboard

A wallboard and partition technology, applied in covering/lining, architecture, building structure, etc., can solve problems such as inability to print patterns, the depth of the depressions cannot be too deep, and the user's requirements for the depth of wallboard concave and convex can not be satisfied. Enhanced firmness and three-dimensional appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

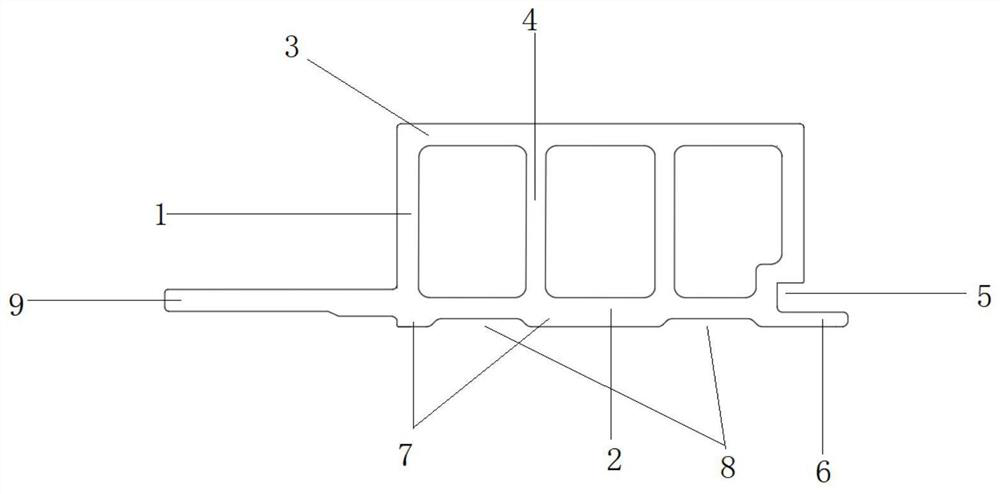

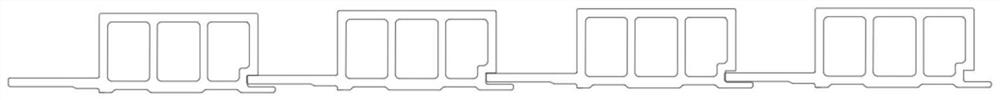

[0017] Such as Figure 1-2 As shown, a spliced wall panel includes a plurality of wall panel assemblies that are spliced with each other, each wall panel assembly includes a wall panel body 1 and a splicing structure, the wall panel body 1 is a frame structure, and the frame is divided into multiple parts by partitions 4 The splicing structure includes an insertion surface 9 extending to the left from the rear side wall 2 of the wall panel body and a groove 5 opened inward on the right side wall of the wall panel body 1, and the width of the groove 5 is the same as that of the insertion surface 9. The thickness is the same, the length of the insertion surface 9 is greater than the depth of the groove 5, and the insertion surface 9 of the latter wall panel assembly is inserted into the groove 5 of the previous wall panel assembly to form a spliced wall panel. A fixing surface 6 extends rightward from the rear end of the right side wall of the wallboard body 1 , and a groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com