Large hollow ceramic tea tray and manufacturing method thereof

A technology of hollow ceramics and a production method, which is applied to trays and other directions, can solve the problems of monotonous color, small size, and insufficient decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

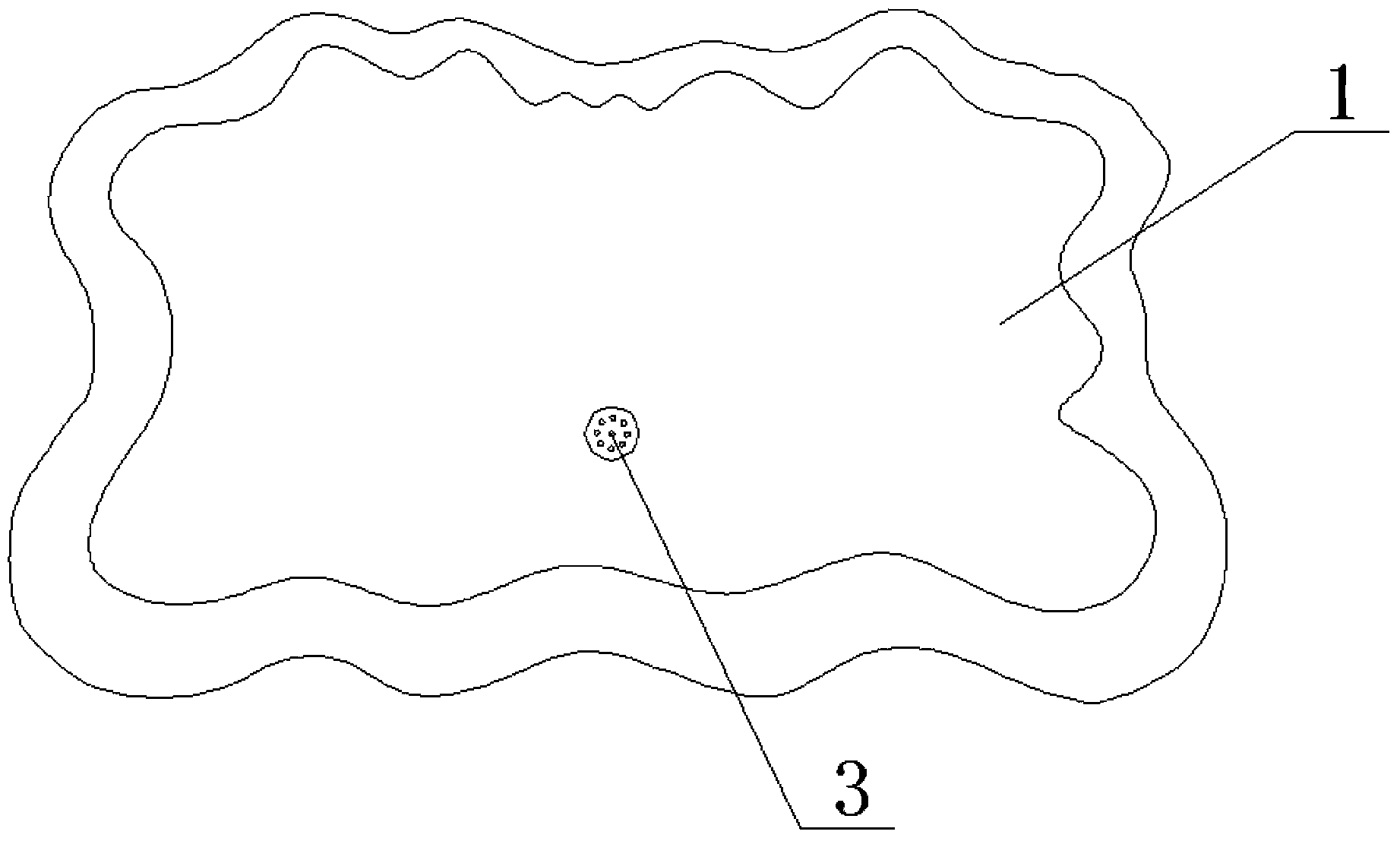

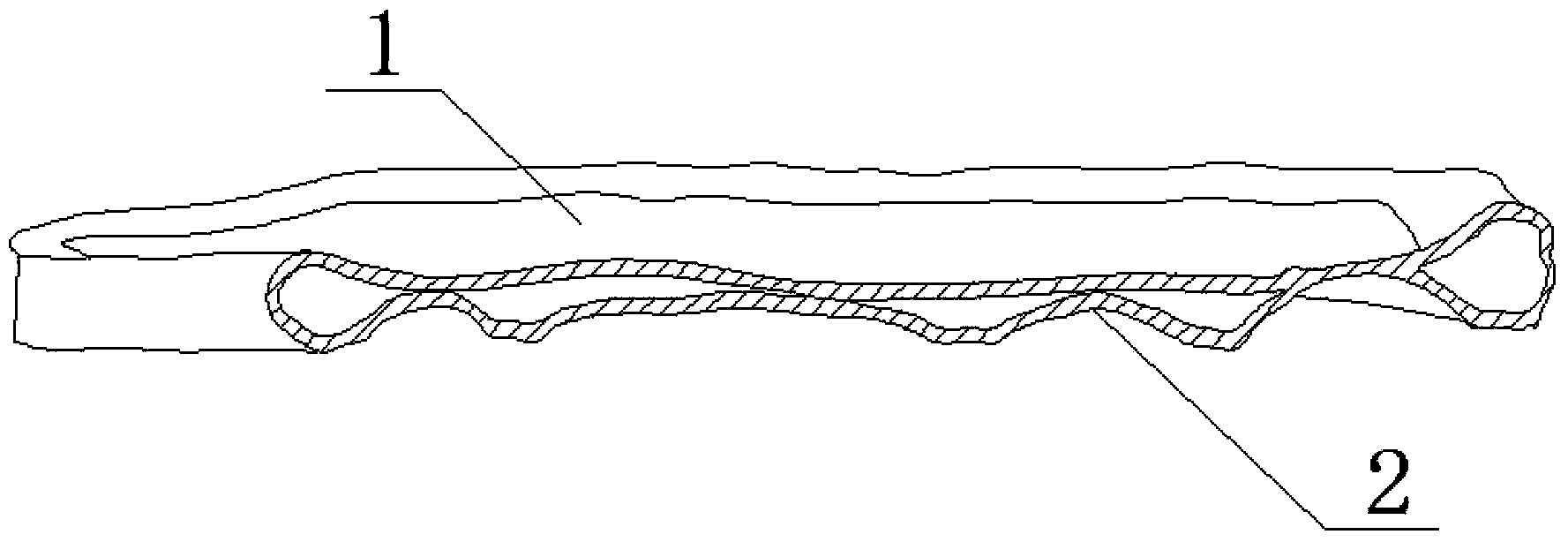

[0045] The ceramic tea tray includes a tray body 1 whose length is more than 50 cm. The interior of the tray body 1 is a hollow structure. The surface of 1 is supported by the support arc surface 2, and the hollow part between the top support points of two adjacent support arc surfaces 2 relies on the pulling force on the plane of the disc body 1 between the two support points to maintain the flatness of the disc body 1, The disk body 1 will not appear unevenness. The edge of the disc body 1 is slightly higher than the surface of the disc body 1 . The surface of the disc body 1 is provided with a drain hole 3, and the bottom of the disc body 1 is provided with a drain pipe 4 communicating with the drain hole 3. There is a drain groove 5 at the bottom edge of the disc body 1 pointed to by the tail of the tail, and the accumulated water on the surface of the disc body 1 can be discharged from the drain pipe 4 through the drain hole 3, and then flows to the outside of the disc b...

Embodiment 2

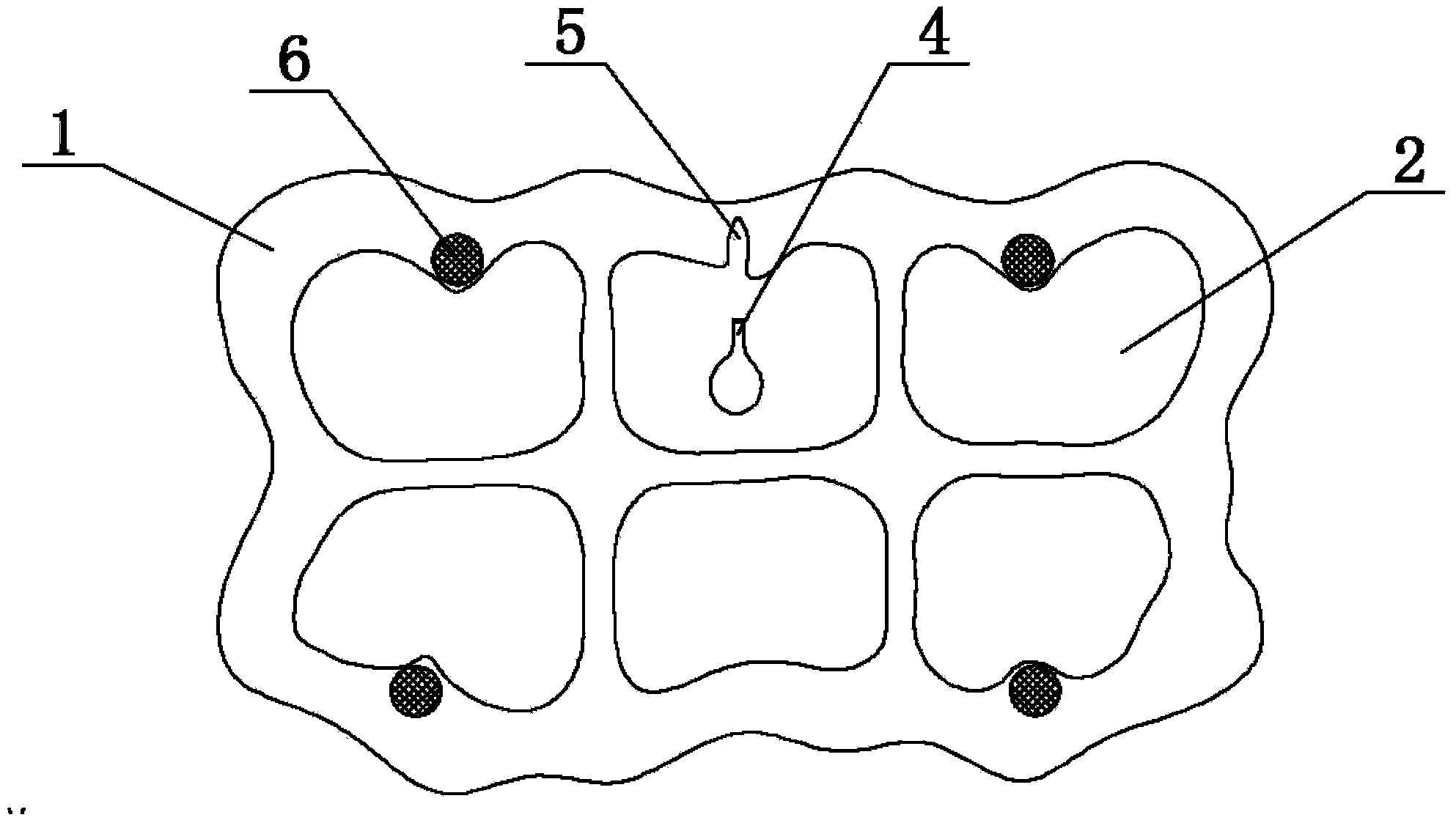

[0056] The ceramic tea tray includes a tray body 1 whose length is more than 50 cm. The interior of the tray body 1 is a hollow structure. The surface of 1 is supported by the support arc surface 2, and the hollow part between the top support points of two adjacent support arc surfaces 2 relies on the pulling force on the plane of the disc body 1 between the two support points to maintain the flatness of the disc body 1, The disk body 1 will not appear unevenness. The edge of the disc body 1 is slightly higher than the surface of the disc body 1 . The surface of the disc body 1 is provided with a drain hole 3, and the bottom of the disc body 1 is provided with a drain pipe 4 communicating with the drain hole 3. A drainage groove 5 is provided at the bottom edge of the tray 1 where the tail of the tail points to. The bottom edge of the disc body 1 and the adjacent positions of the support arc surfaces 2 form a plane. A rubber anti-slip pad 6 is provided near the edge of the ...

Embodiment 3

[0069]The ceramic tea tray includes a tray body 1 whose length is more than 50 cm. The interior of the tray body 1 is a hollow structure. The surface of 1 is supported by the support arc surface 2, and the hollow part between the top support points of two adjacent support arc surfaces 2 relies on the pulling force on the plane of the disc body 1 between the two support points to maintain the flatness of the disc body 1, The disk body 1 will not appear unevenness. The edge of the disc body 1 is slightly higher than the surface of the disc body 1 . The surface of the disc body 1 is provided with a drain hole 3, and the bottom of the disc body 1 is provided with a drain pipe 4 communicating with the drain hole 3. A drainage groove 5 is provided at the bottom edge of the tray 1 where the tail of the tail points to. The bottom edge of the disc body 1 and the adjacent positions of the support arc surfaces 2 form a plane. A rubber anti-slip pad 6 is provided near the edge of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com