A half-value compensator for different diameters of hot water heating pipes and its laying method

A technology of compensator and reducing diameter, which is applied in expansion compensating devices for pipelines, pipeline laying and maintenance, and pipe components, etc., which can solve the problems of large volume of fixed piers, increase of fault sources of piping systems, and increase of lateral displacement of nearby branches, etc. , to achieve the effect of saving investment, reducing the scope of construction influence and reducing the source of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

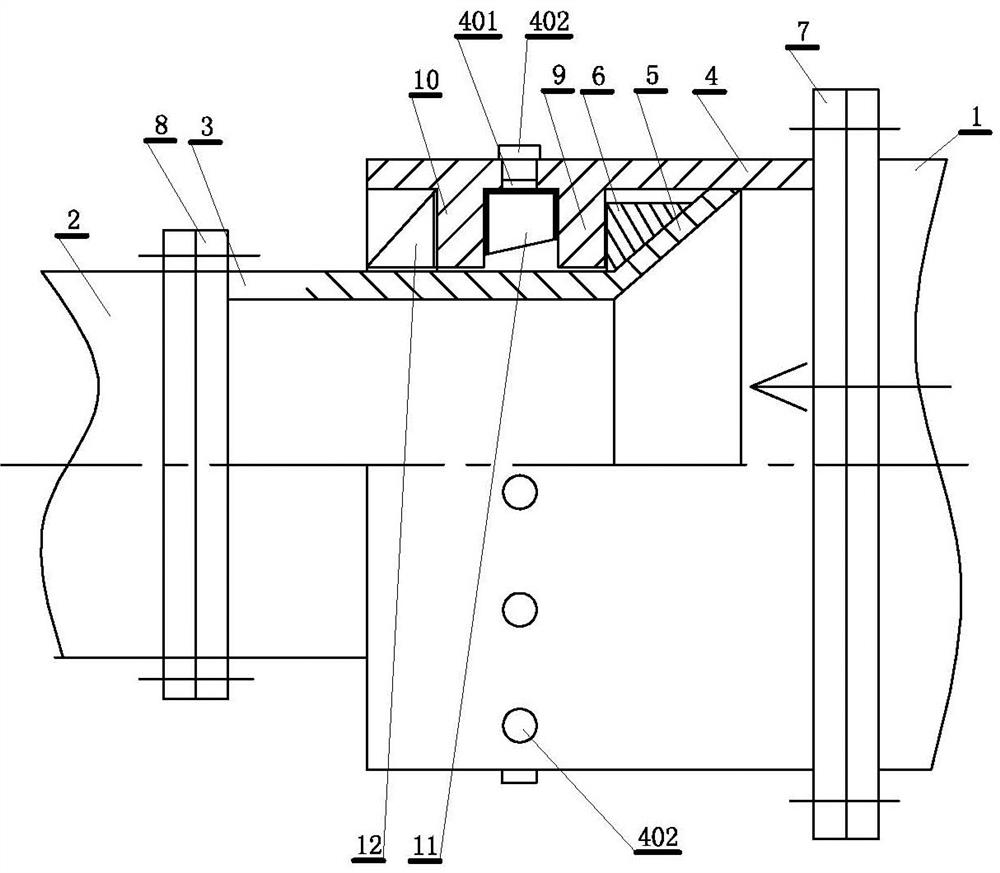

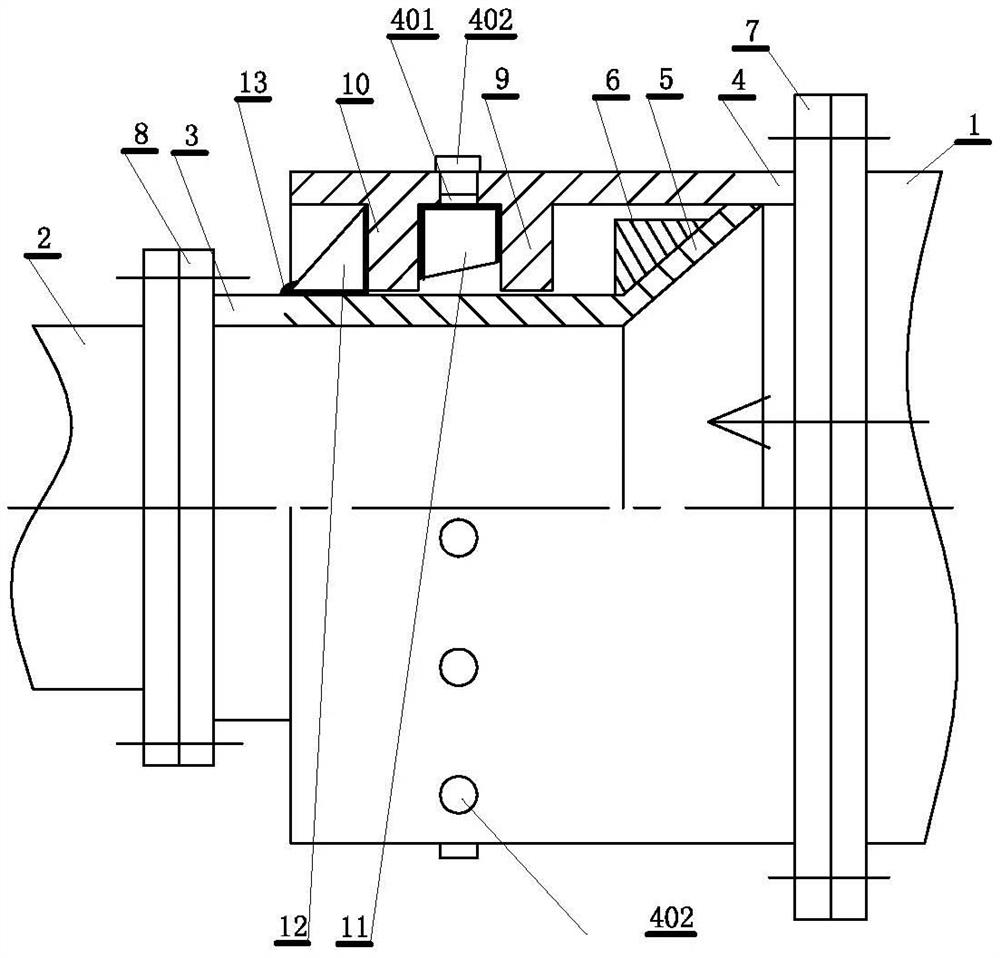

[0027] A hot water heat supply pipe different diameter half value compensator, such as figure 1 and figure 2 As shown, the different-diameter half-value compensator is arranged between the large-diameter pipe 1 and the small-diameter pipe 2 of the directly buried heating pipeline, wherein the different-diameter half-value compensator includes an inner straight pipe 3 and an outer straight pipe 4 , the inner sleeve straight pipe and the outer sleeve straight pipe are arranged in a set, the arrow in the figure is the water flow direction, the diameter of the inner sleeve straight pipe is equal to the diameter of the small diameter pipe, and the diameter of the outer sleeve straight pipe is equal to the diameter of the large diameter pipe. One end of the straight tube of the inner sleeve is connected to a diversion ring 5 with a different diameter in the form of a bell mouth in the straight tube of the outer sleeve. The large diameter end of the diversion ring with a different ...

Embodiment 2

[0033] A method for laying a different-diameter half-value compensator based on Embodiment 1. The different-diameter half-value compensator includes an inner sleeve straight pipe and an outer sleeve straight pipe, and the inner sleeve straight pipe and the outer sleeve straight pipe are nested, and the inner sleeve straight pipe One end is connected to a different-diameter guide ring with a bell mouth in the outer straight tube, the large-diameter end of the bell mouth of the different-diameter guide ring slides and fits with the inner wall of the outer straight tube, and the outer wall of the inner straight tube is close to the different-diameter guide. The small-diameter end of the flow ring bell mouth is fixed with an anti-pull-out gear ring, and the outer straight tube covers the anti-pull-off gear ring and protrudes forward. The protruding outer straight tube surrounds the inner wall and is provided with a support ring. There is a sliding gap between the straight pipes, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap