A flexible job shop scheduling optimization method

A technology of workshop scheduling and optimization methods, applied in data processing applications, forecasting, instruments, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

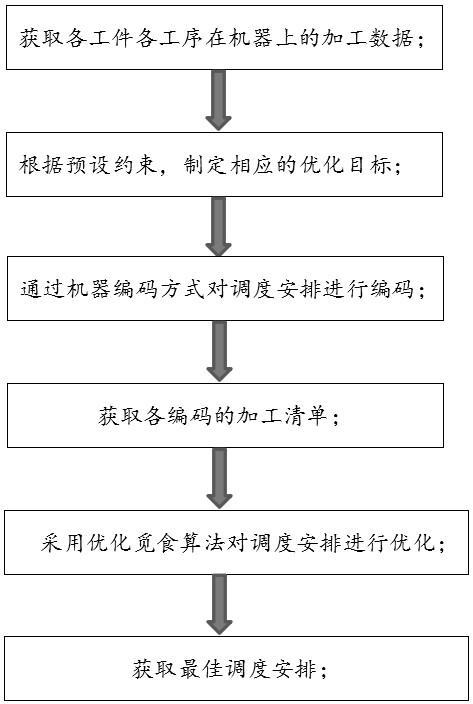

[0051] Please refer to figure 1 , the present invention provides a flexible job shop scheduling optimization method, comprising the following steps:

[0052] 1. Obtain the processing data of each workpiece and process on the machine

[0053] Table 1:

[0054]

[0055] in FIG. 1:

[0056] o ij : Workpiece J i The jth process of ;

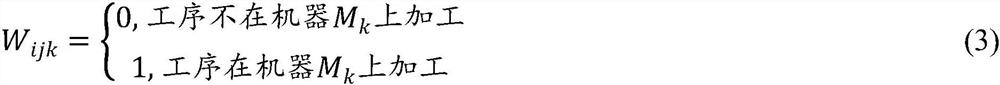

[0057] T ijk : Workpiece J i The jth process of the machine M k processing time on

[0058] Among them, T ijk A positive real number indicates that the process can be processed on the machine M k upper processing, T ijk Does not exist means that the process cannot be performed on machine M k on processing. Then the process O ij Optional machine set M ij for T ijk Existing machine M k collection.

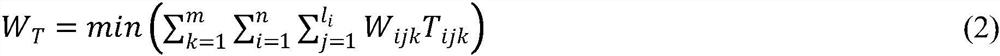

[0059] 2. Formulate optimization goals

[0060] In actual production, there are many optimization objectives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com