Pvc glove raw material mixing static tank and using method thereof

A technology of mixing tank and static tank is applied in the field of PVC glove raw material mixing and static tank, which can solve the problems of inability to achieve mixing, low mixing efficiency, and increased equipment mixing cost.

Active Publication Date: 2022-05-31

安徽和佳医疗用品科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problem that in the prior art, in the production process of PVC gloves, the raw materials need to be mixed first, but the traditional raw material mixing device has low mixing efficiency, and the mixing area is relatively limited, and only one stirring rod cannot To achieve efficient mixing, the problem of increasing the mixing cost of the entire device is proposed, and a PVC glove raw material mixing static tank and its use method are proposed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

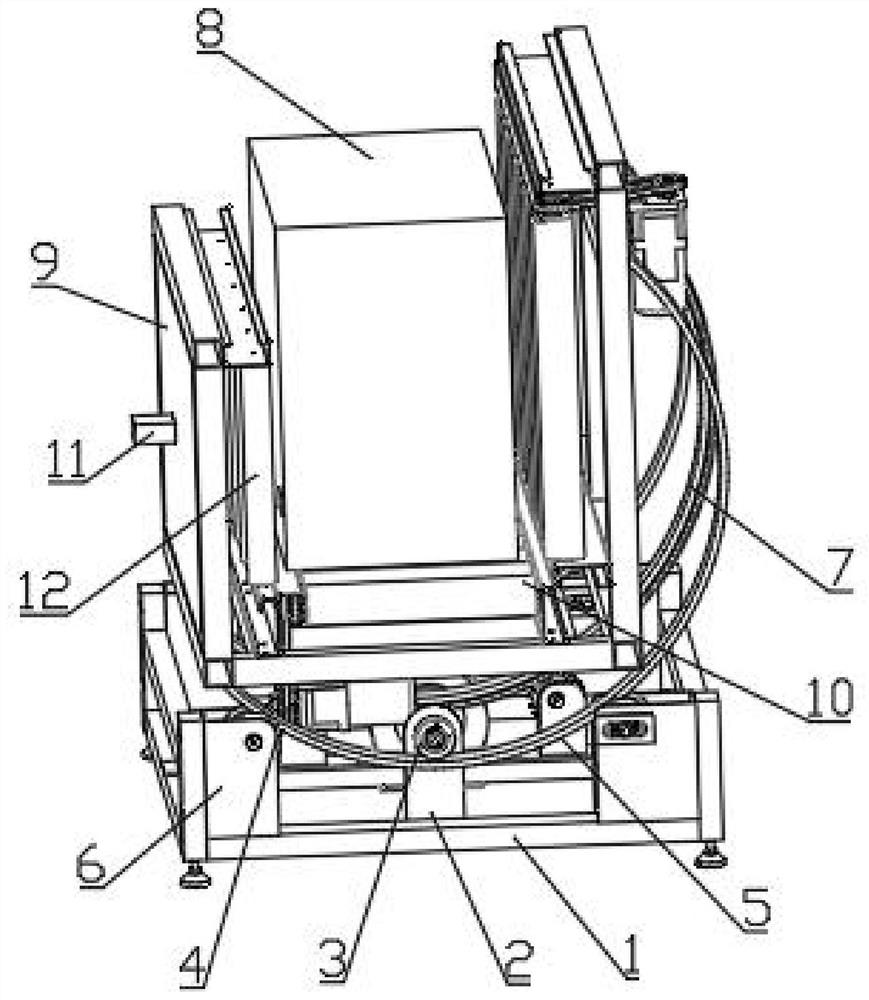

[0036] The horizontal portion of the U-shaped fixed plate 9 is provided with a conveying roller 10, and the bottom of the mixing tank 8 is located on the conveying roller 10.

[0043] The preferred embodiments of the present invention disclosed above are provided only to assist in illustrating the present invention. Preferred embodiments are not exhaustive

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

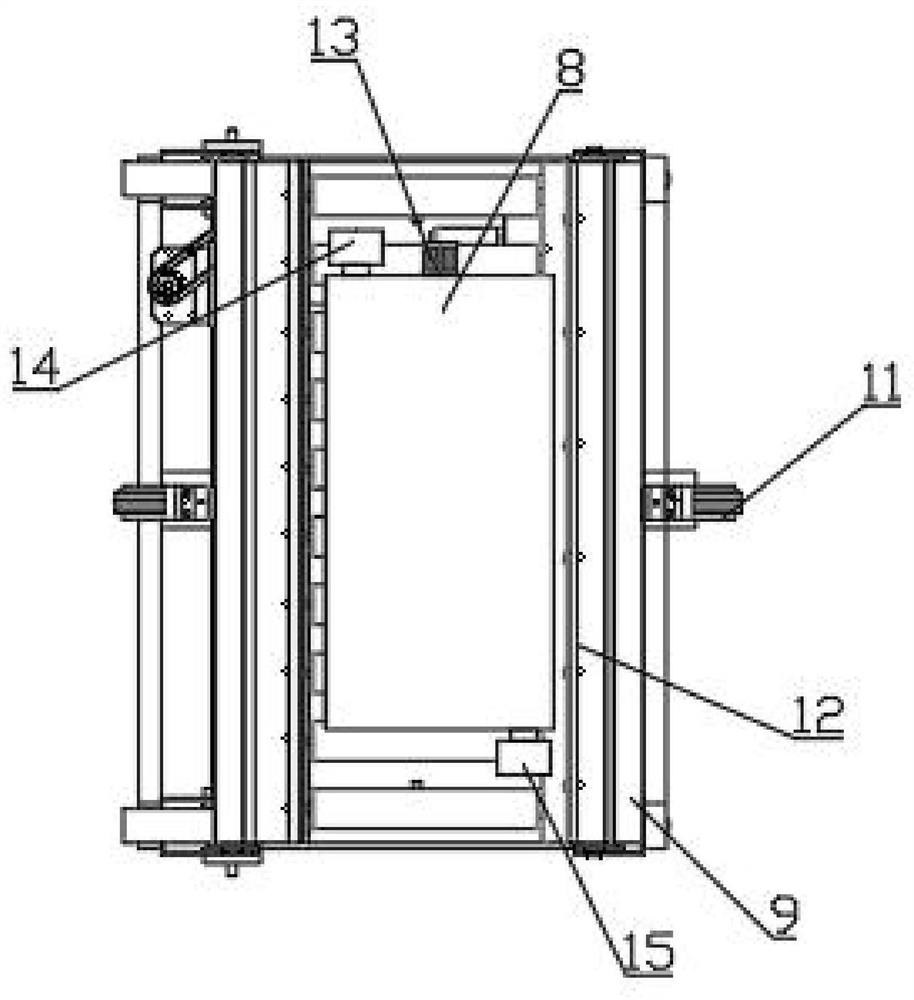

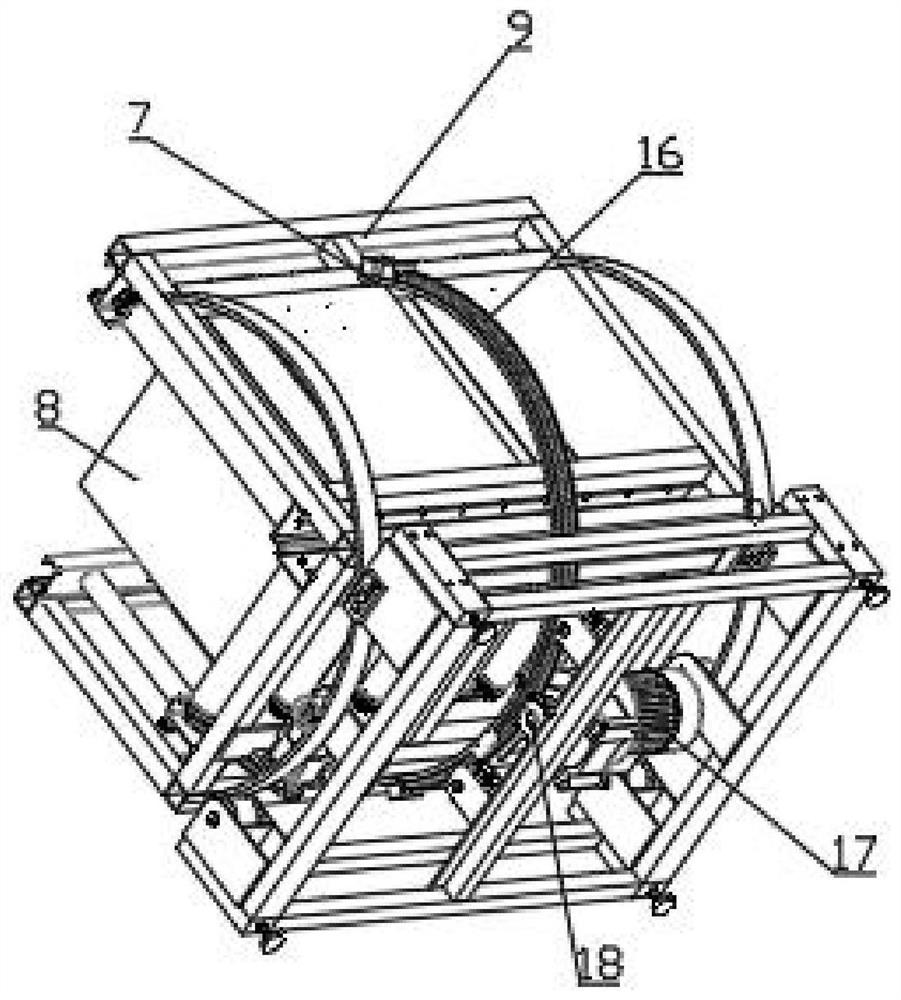

The invention discloses a static tank for mixing raw materials of PVC gloves, which comprises a base, a shaking mechanism and a stirring mechanism; The middle part of the top surface of the base is equipped with a limit plate, and the limit plate is provided with a first limit wheel; the two sides of the U-shaped fixed plate are respectively provided with a first arc plate, and the first arc plate is located on the first limit wheel. The bottom of the U-shaped fixed plate is rotatably connected with the first limiting wheel, the first arc-shaped plate is located at the top of the second limiting wheel, and is rotatably connected with the second limiting wheel; the vertical parts on both sides of the U-shaped fixed plate are respectively provided with Clamping mechanism, the cylinder is installed on the side wall of the U-shaped fixed plate, and the output end of the cylinder passes through the side wall of the U-shaped fixed plate, and is connected with the splint, and the side wall of the mixing tank is located between two groups of splints; the present invention Through the cooperating work of the swaying mechanism and the stirring mechanism, the efficiency of stirring and mixing the PVC glove raw materials by the mixing tank is greatly improved.

Description

PVC glove raw material mixing stand tank and its use method technical field The invention belongs to the technical field of PVC gloves, relates to a mixing tank and a method of using the same, and is specifically a raw material for PVC gloves. Material mixing stand tank and its use method. Background technique Insulating gloves are usually made of rubber, latex or plastic molding, and have the characteristics of anti-electricity, water resistance, acid and alkali corrosion resistance, etc. It is widely used in the electric power industry, automobile and machinery maintenance, chemical industry, precision installation and other industries. In the prior art, in the production process of PVC gloves, the raw materials need to be mixed at first, and the traditional raw materials are mixed. The mixing efficiency of the device is low, and the mixing area is relatively limited. Only one stirring rod cannot achieve efficient mixing, which makes the entire equipment Increase...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29B7/16B29B7/22B29B7/80B08B9/087B29K27/06

CPCB29B7/16B29B7/22B29B7/802B08B9/087B29K2027/06

Inventor 张伯侯马万青张天柱董松

Owner 安徽和佳医疗用品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com