Combined inclined strut supporting pile

A supporting pile and combined technology, applied in sheet pile walls, excavation, construction, etc., can solve the problems of difficult excavation, long construction period, water leakage of the supporting body, etc., and achieves low cost, complete protection components, and increased size The effect of compressive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

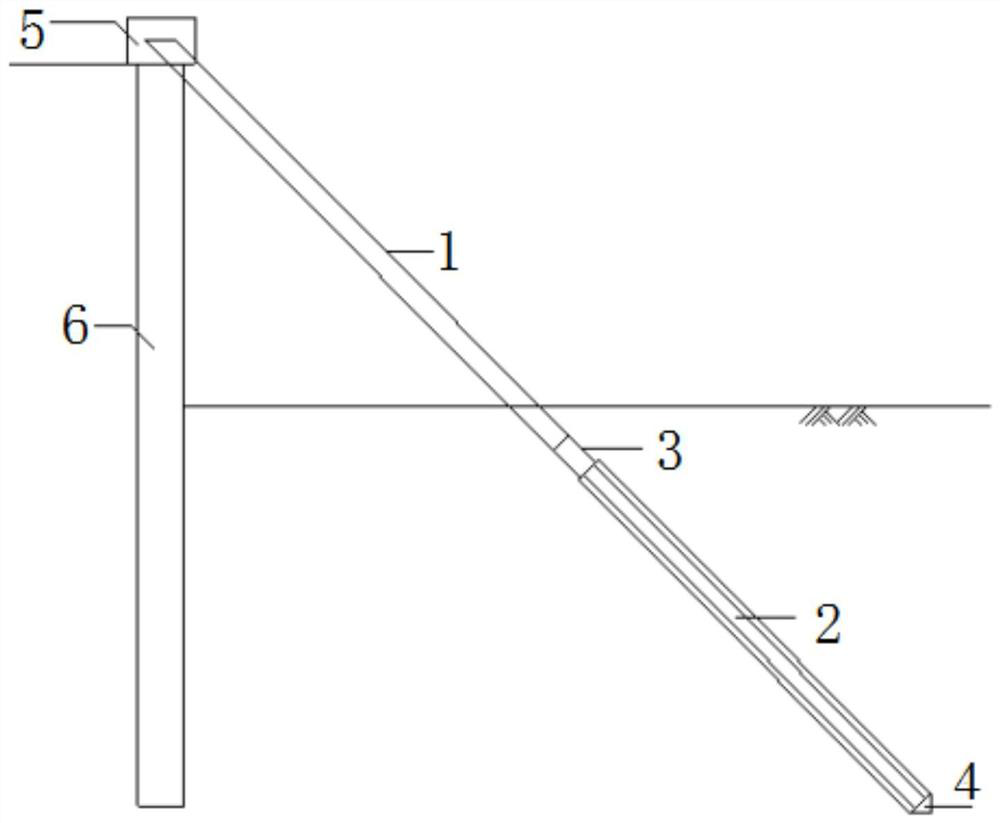

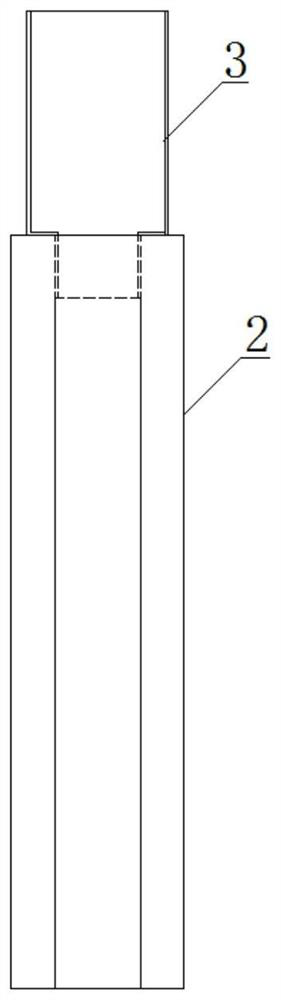

[0020] see figure 1 and figure 2 , the prefabricated pile 2 is a square pile, the mitered pile 1 is a steel pipe, the bracing connector 3 is a short steel pipe, the lower end of the short steel pipe is embedded in the top of the square pile, the upper end of the short steel pipe is connected to the inclined The bottom end of the steel pipe connecting pile 1 is connected.

[0021] The specific implementation method is as follows: the pile tip 4 is set at the pile end of the prefabricated pile 2; after the construction of the surrounding protection pile 6 is completed, the prefabricated pile 2 is driven obliquely, and the pile head is exposed to the ground; the prepared short steel pipe is embedded in the precast pile 2 and connected After completion, lift the miter pile 1 and connect it with the bracing connector 3; after the node connection is completed, continue to drive steel pipes to the design elevation; pour the ring beam 5 to form a whole.

[0022] Construction effect...

no. 2 example

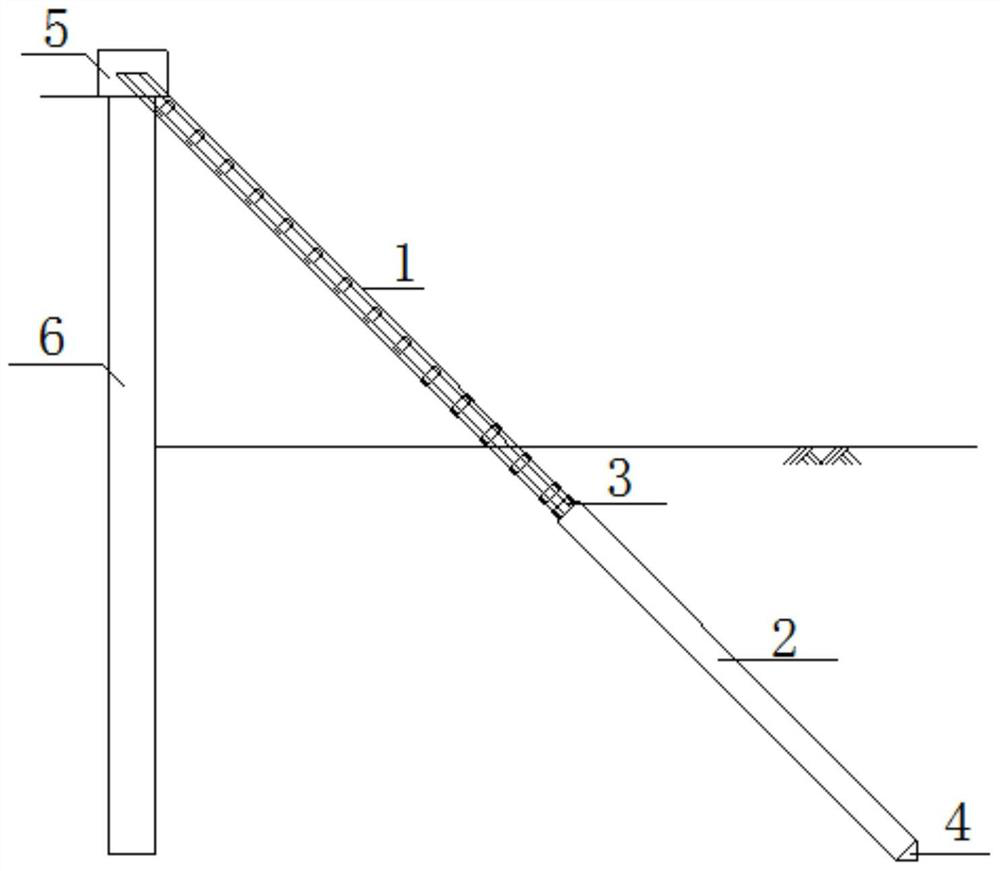

[0024] see image 3 and Figure 4 , the prefabricated pile 2 is a prefabricated square pile or a prefabricated pipe pile, the mitered pile 1 is a lattice column, and the diagonal brace connector 3 is an angle steel, and the lower end of the lattice column is connected to the prefabricated pile through the angle steel 2's upper connection.

[0025] The specific implementation method is as follows: the pile tip 4 is set at the pile end of the prefabricated pile 2, and the angle steel is set at the end plate of the pile head; The head is exposed to the ground; the lattice column is lifted and connected with the angle steel, and after the joint connection is completed, the lattice column is continued to be driven to the design elevation; the ring beam 5 is poured to form a whole.

[0026] Construction effect: ①The upper part adopts lattice columns to ensure the stability under pressure; the lower part adopts prefabricated piles (prefabricated square piles or prefabricated tubula...

no. 3 example

[0028] see Figure 5 and Figure 6 , the prefabricated pile 2 adopts a prefabricated square pile or a prefabricated pipe pile, the miter pile 1 adopts section steel, the diagonal bracing connector 3 adopts a rib plate, and a steel plate 7 and a prefabricated pile end plate 8 are arranged, and the rib plate and the steel plate 7 is fixedly connected to the lower end of the miter pile 1 and connected to the prefabricated pile end plate 8 at the top of the prefabricated pile 2 by bolts.

[0029] Further, a waterproof steel sheet 9 is also provided on the miter pile 1 .

[0030] The specific implementation method is as follows: set ribs and steel plates 7 at the lower end of the mitered pile 1 using section steel, and set the pile tip 4 at the pile end of the prefabricated pile 2; The head is exposed to the ground by about 1m; the mitered pile 1 is lifted, and the steel plate 7 and the prefabricated pile end plate 8 are connected by bolts; after the joint connection is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com