Commercial vehicle air dryer oil filtering efficiency test device and method thereof

An air dryer and efficiency test technology, which is used in measuring devices, testing of machine/structural components, instruments, etc., can solve the problem that the absolute value of oil filtration efficiency cannot be accurately obtained, the error of the test value is large, and the amount of oil channeling should not be controlled. and other problems to achieve the effect of reducing the test cycle, testing accuracy, and verifying oil filter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

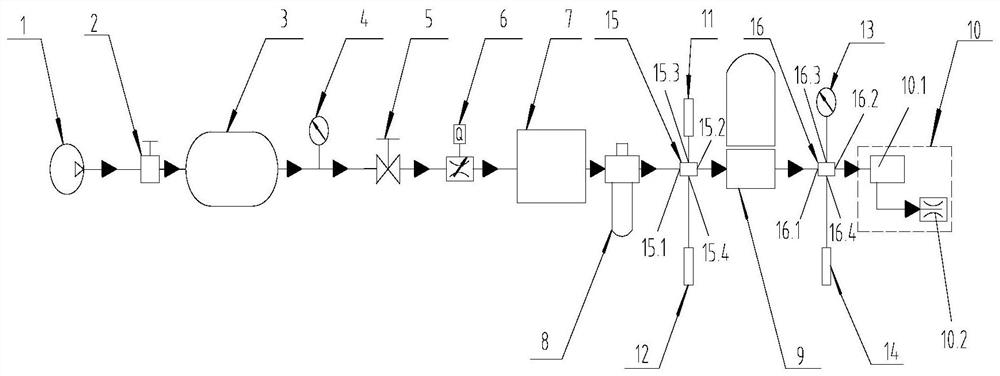

[0033] Such as figure 1 Shown is a commercial vehicle air dryer oil filtration efficiency test device, including an air source 1, a pressure reducing valve 2, an air storage tank 3, a first pressure gauge 4, a stop valve 5, a flow adjustment display device 6, a compressed air heating Device 7, oil mist device 8, air dryer 9, simulated air consumption device 10, temperature detection and display device 11, temperature-resistant compressed air oil content detection and display device 12, second pressure gauge 13 and compressed air oil content detection and display device 14; Air source 1, pressure reducing valve 2, air storage tank 3, first pressure gauge 4, stop valve 5, flow adjustment display device 6, compressed air heater 7, lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com