Coil made of a coiled metal strip having a marking, and use of said marking

A technology for metal strips and coils, applied in the field of metal strips, can solve the problems of lack of marks, loss of identification of metal strips, and no longer possible to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

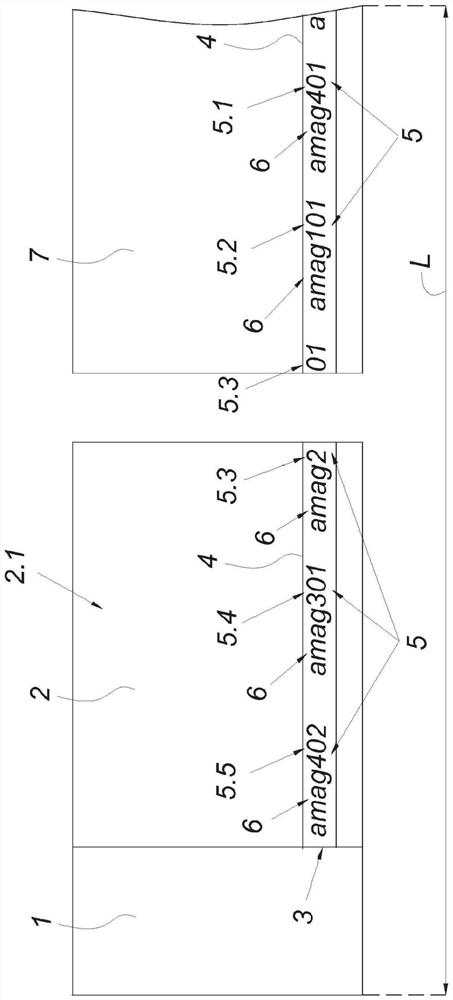

[0030] according to figure 1 For example, a metal strip 2 , ie an aluminum strip, wound into a coil 1 or coil is shown according to the first embodiment, which has markings 3 on the flat side 2 . 1 for preferably unambiguous identification of the coil 1 . Markings 3 are printed onto the metal strip 2 . However, this marking 3 can also be provided on a label glued to the metal strip 2 , which is not shown in detail in the figures.

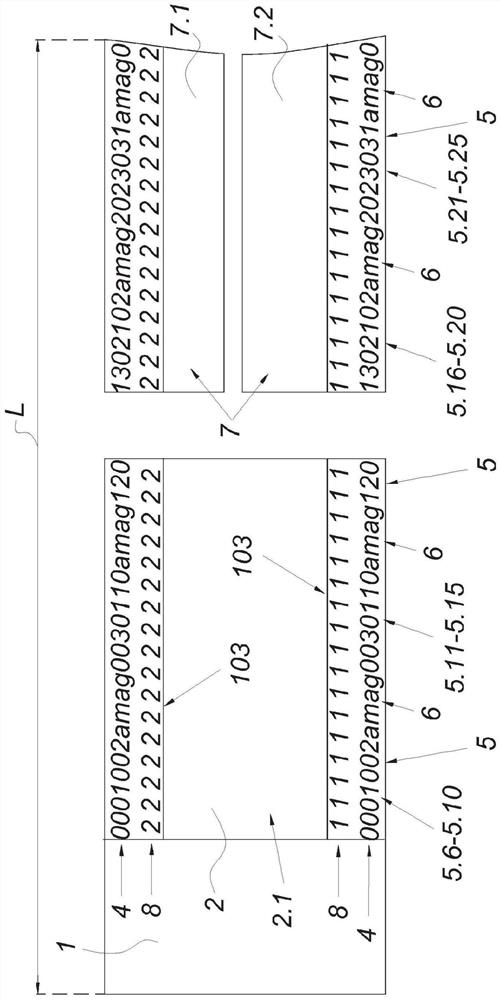

[0031] According to the invention, the printed marking 3 has an information track 4 . This information track 4 is arranged over the entire length L of the metal strip 2 , more precisely in the region of the longitudinal edges of the metal strip 2 . Furthermore, this information track 4 has successively arranged words 5.1, 5.2, 5.3, 5.4, 5.5 of the De Bruijn sequence 5 . For better clarity, the words 5.1, 5.2, 5.3, 5.4, 5.5 are separated from each other by spaces in figure 1 is shown in , but it is entirely conceivable to form tag 3 without space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com