Magnesium alloy sheet preparation method and device for implementing method

A magnesium alloy and sheet technology, applied in the field of material processing, can solve the problems of low production capacity and high preparation cost, and achieve the effect of avoiding magnesium alloy waste and solving the high preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The first aspect of the present invention provides a kind of preparation method of magnesium alloy sheet, and described method comprises the following steps:

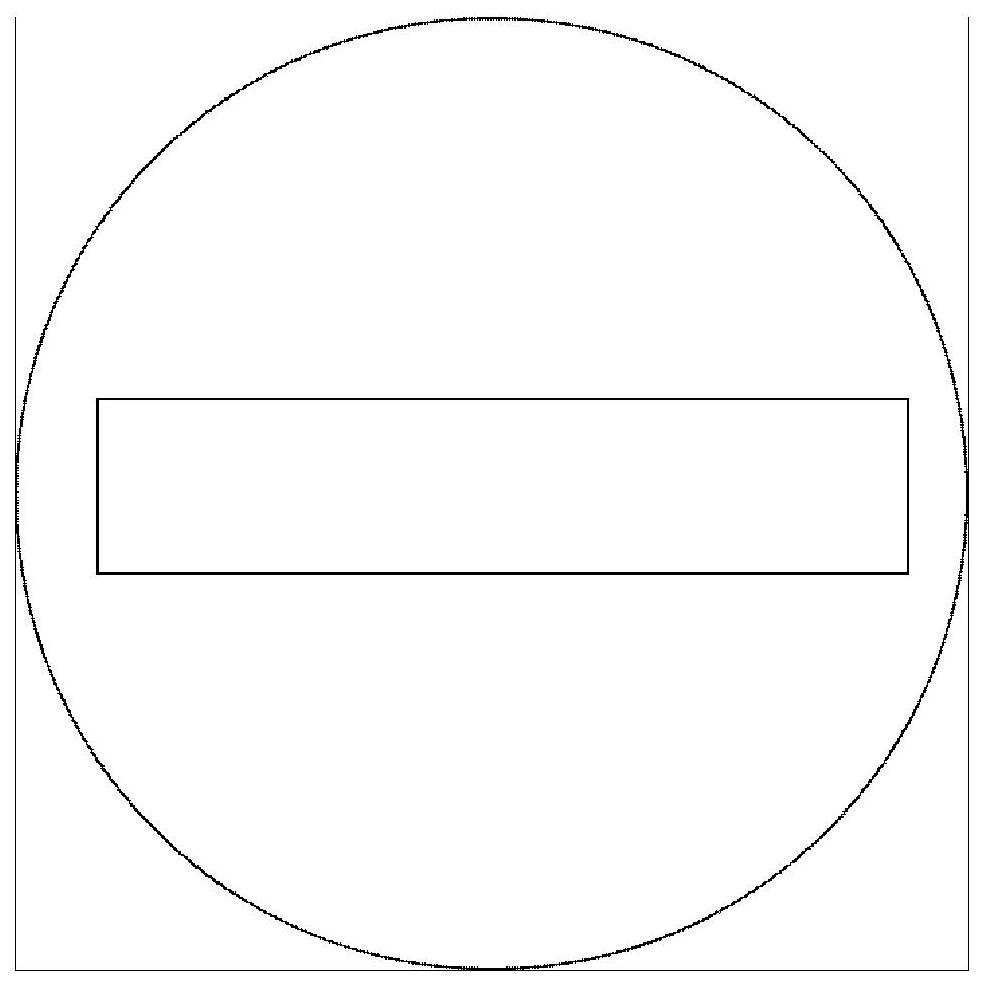

[0047] Step 1. Extruding the magnesium alloy billet to obtain a curved magnesium alloy sheet with a thickness of 0.6-1.0mm, wherein the extrusion speed is 0.6-3.0mm / s;

[0048] Step 2, flattening the arc-shaped magnesium alloy sheet to obtain the magnesium alloy sheet.

[0049] Wherein, the "magnesium alloy sheet" mentioned in the present invention refers to a magnesium alloy sheet with a thickness of 0.6-1.0 mm, suitable for 3C products.

[0050] The invention provides a method for preparing a magnesium alloy thin plate. Magnesium alloy blanks are sequentially subjected to extrusion treatment and flattening treatment. The extrusion die at the extrusion outlet is extruded to obtain an arc-shaped magnesium alloy sheet that meets the corresponding thickness requirements, and then the arc-shaped magnesium alloy she...

Embodiment 1

[0079] The preparation method provided in this embodiment comprises the following steps:

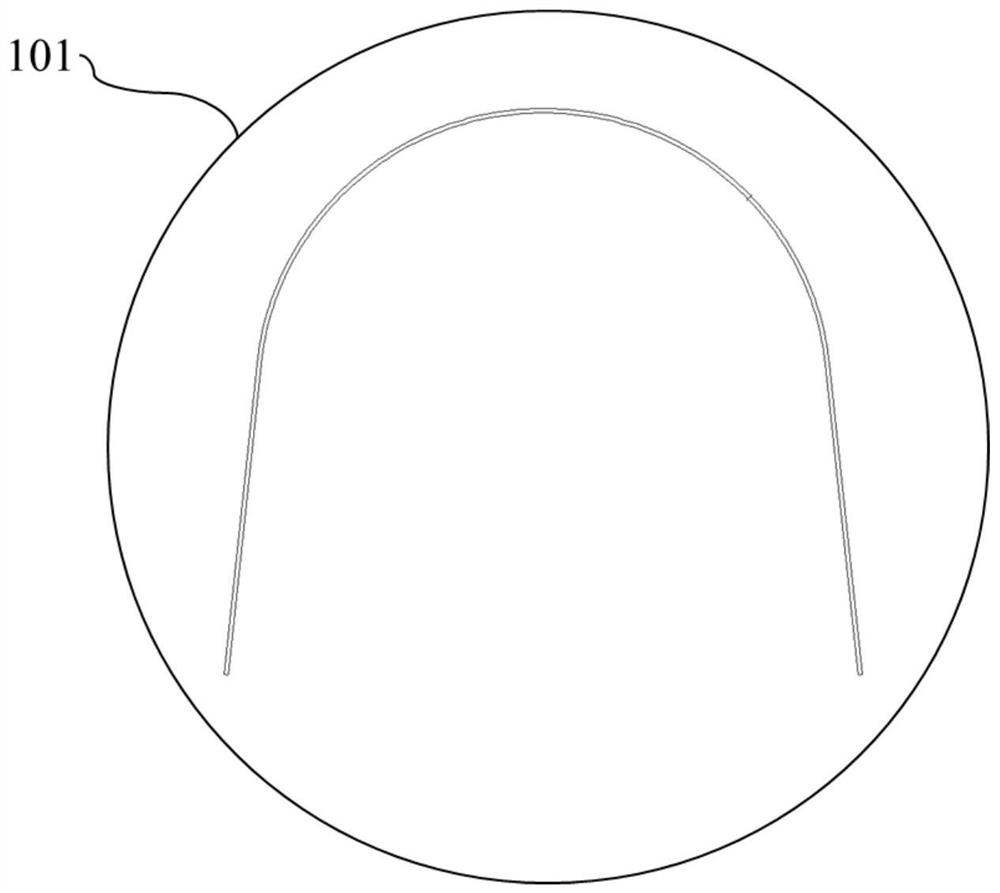

[0080] Step 1, the cross section of the extrusion die used in this embodiment is as follows image 3 As shown, and the width of the arc extrusion outlet is 0.6mm,

[0081] First, preheat the magnesium alloy billet to 380±20°C, preheat the extrusion cylinder to 380±15°C, preheat the extrusion die to 400±20°C, and control the extrusion speed to 0.8-1.5mm / s (extrusion During the pressing process, the highest extrusion speed can reach 1.5mm / s, and the extrusion speed during stable production is 1.0mm / s), and the arc-shaped magnesium alloy sheet with a thickness of 0.6mm can be obtained by extrusion, and the transverse direction of the arc-shaped magnesium alloy sheet Section shape and image 3 Extrusion outlets shown are the same;

[0082] Step 2, flattening the arc-shaped magnesium alloy sheet through a three-stage flattening unit to obtain a flat magnesium alloy sheet;

[0083] Step 3,...

Embodiment 2

[0087] The preparation method provided in this embodiment comprises the following steps:

[0088] Step 1, the cross section of the extrusion die used in this embodiment is as follows Figure 4 As shown, and the width of the arc extrusion outlet is 1.0mm,

[0089] First, preheat the magnesium alloy billet to 400±20°C, preheat the extrusion cylinder to 400±20°C, preheat the extrusion die to 400±20°C, and control the extrusion speed to 1.2-2.0mm / s (extrusion During the pressing process, the highest extrusion speed can reach 2.0mm / s, and the extrusion speed during stable production is 1.5mm / s), and the arc-shaped magnesium alloy sheet with a thickness of 1.0mm can be obtained by extrusion, and the transverse direction of the arc-shaped magnesium alloy sheet Section shape and Figure 4 Extrusion outlets shown are the same;

[0090] Step 2. Flatten the arc-shaped magnesium alloy sheet through a three-stage flattening unit to obtain a flat magnesium alloy sheet.

[0091] Step 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com