Small plano-convex lens edge grinding and polishing equipment

A plano-convex lens, small technology, used in grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding workpiece edges, etc. , to achieve the effect of accurate placement and avoid injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

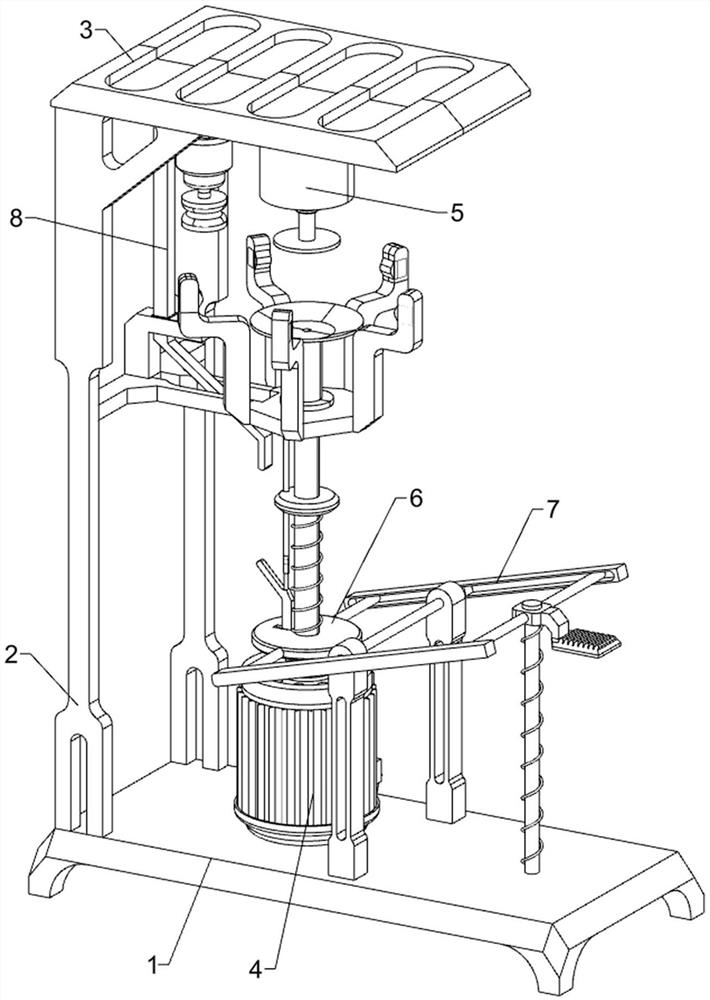

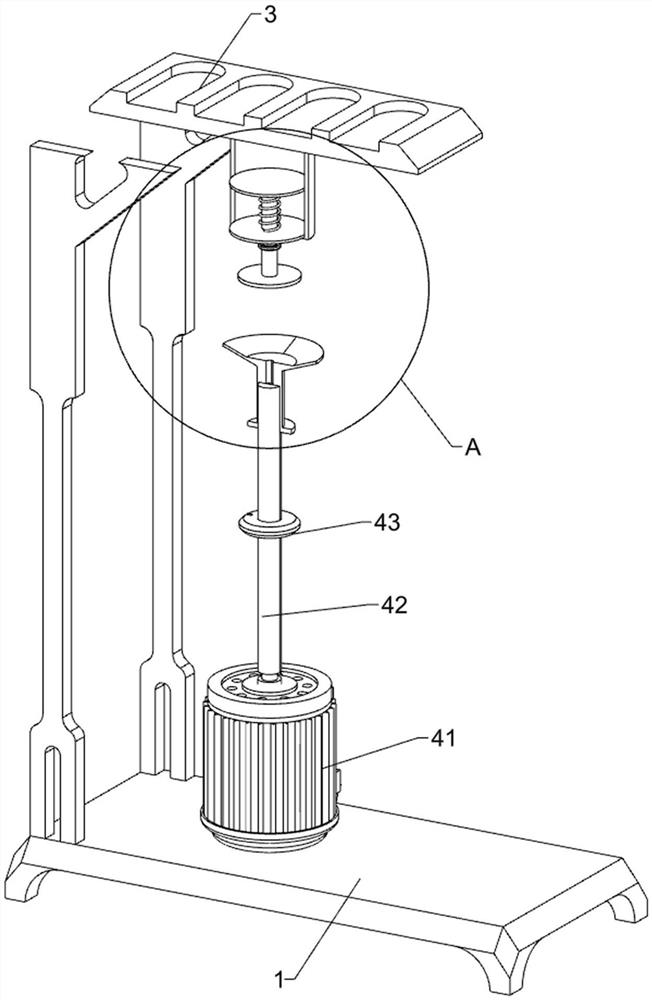

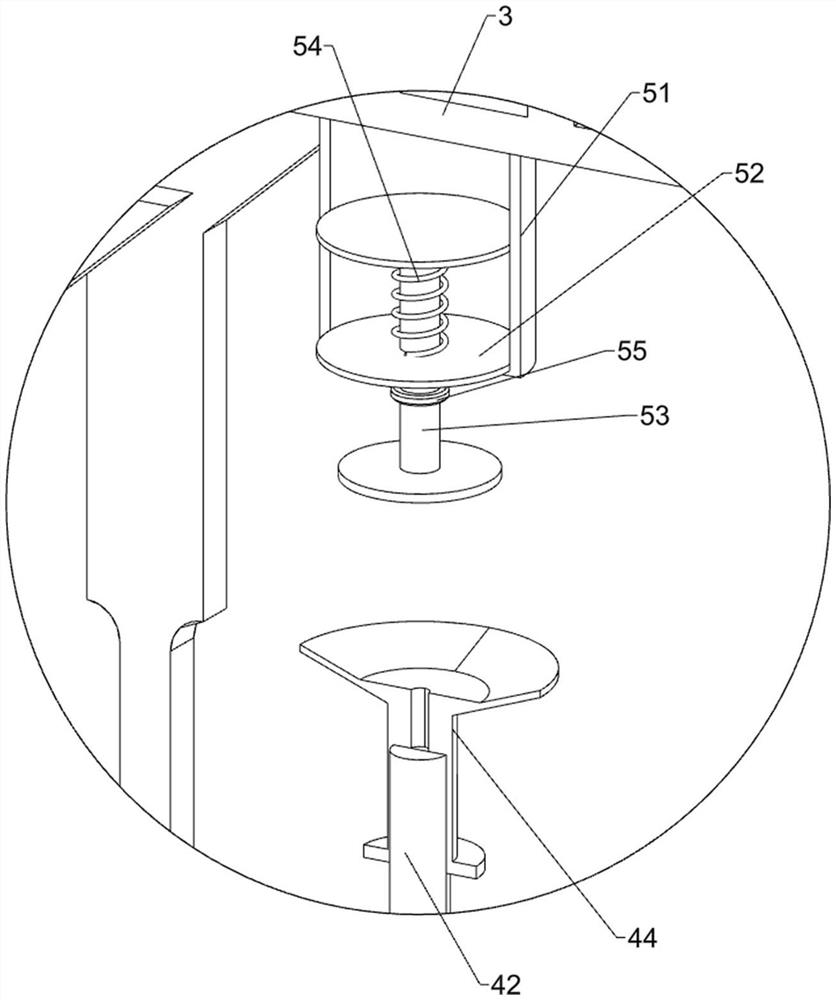

[0027] A small plano-convex lens edge grinding and polishing equipment, such as Figure 1-Figure 3 As shown, it includes a base 1, a first support rod 2, a support plate 3, a rotating assembly 4, and a clamping assembly 5. The left side of the top of the base 1 is fixed with the first support rod 2 symmetrically front and back, and the first support rods on the front and rear sides 2. A support plate 3 is fixedly connected between the top ends. A clamping assembly 5 is provided in the middle on the right side of the bottom of the support plate 3. A rotating assembly 4 is provided in the middle on the left side of the top of the base 1. The rotating assembly 4 cooperates with the clamping assembly 5.

[0028] The rotating assembly 4 includes a geared motor 41, a slide bar 42, a connection plate 43 and a suction cup 44. A geared motor 41 is installed in the middle of the left side of the top of the base 1. The output shaft of the geared motor 41 is slidably covered with a slide b...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 and Figure 7 As shown, an auxiliary limit assembly 6 is also included, and the auxiliary limit assembly 6 includes a sliding plate 61, a second spring 62, a first special-shaped limit rod 63, a fourth spring 64, a push rod 66, a mounting plate 67, a limit Bit cap 68, the fourth connecting rod 69 and the eighth spring 610, a mounting plate 67 is affixed between the top of the first support rod 2 inner side surfaces of the front and rear sides, the slide bar 42 runs through the middle of the right part of the mounting plate 67, and the mounting plate 67 right There is a push rod 66 slidingly connected between the middle of the part and the left part of the connection plate 43, the top of the push rod 66 is fixedly connected with the limit cap 68, the limit cap 68 is in contact with the bottom of the suction cup 44, and the bottom end of the push rod 66 is sliding. The fourth connecting rod 69 is place...

Embodiment 3

[0037] On the basis of embodiment 1 and embodiment 2, such as figure 1 , Figure 4 , Figure 6 and Figure 7 As shown, a power assembly 7 is also included, and the power assembly 7 includes a second support rod 71, a lever frame 72, a first connecting rod 73, a second connecting rod 74, a third connecting rod 75, a pedal 76 and a fifth spring 77. A second support rod 71 is fixedly connected to the front and back symmetrically in the middle of the top of the base 1, and the upper part of the second support rod 71 on the front and rear sides is rotatably connected with a prying frame 72, and the left parts of the front and rear sides of the prying frame 72 are all sliding The first connecting rod 73 is provided, and the inner ends of the first connecting rod 73 on the front and rear sides are fixedly connected with the outer circumferential direction of the sliding plate 61, and the middle of the right side of the top of the base 1 is fixedly connected with a second connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com