A system and method for automatic identification of fuel injection for vehicles

A technology of automatic oil filling and vehicle identification, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of low automation, low oil filling efficiency, long oil filling time, etc., achieve high automation and shorten oil filling time , Improve the effect of oil injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

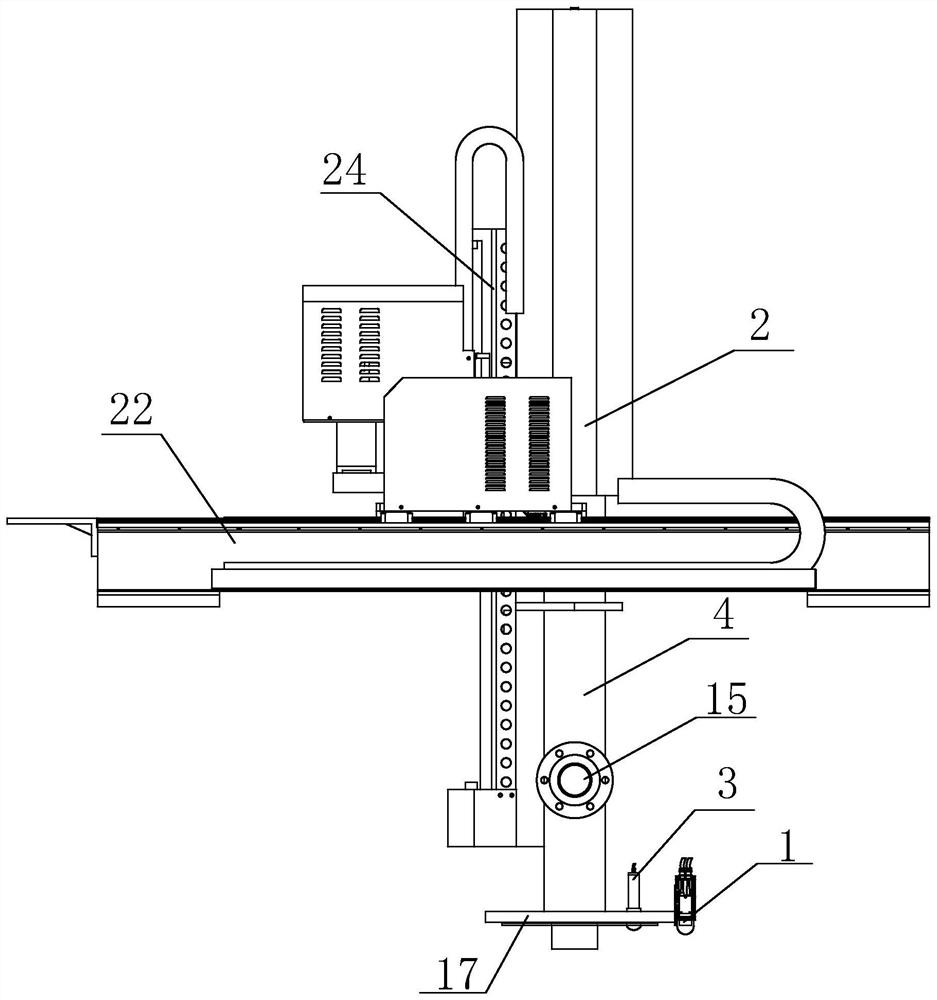

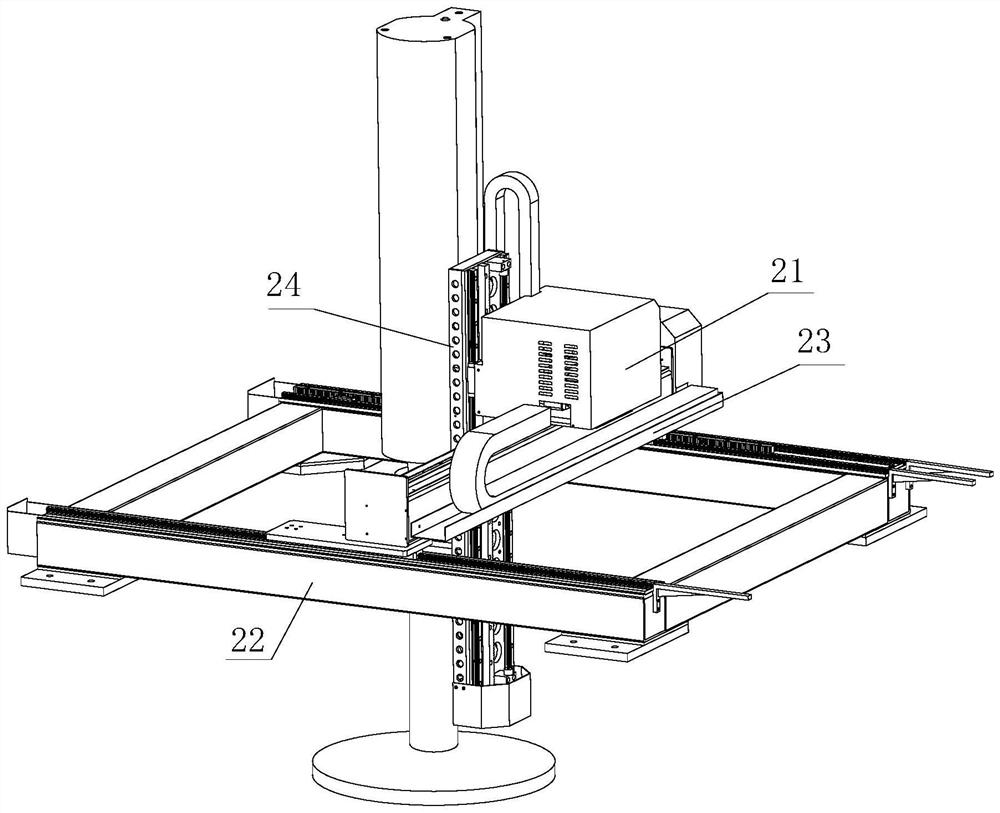

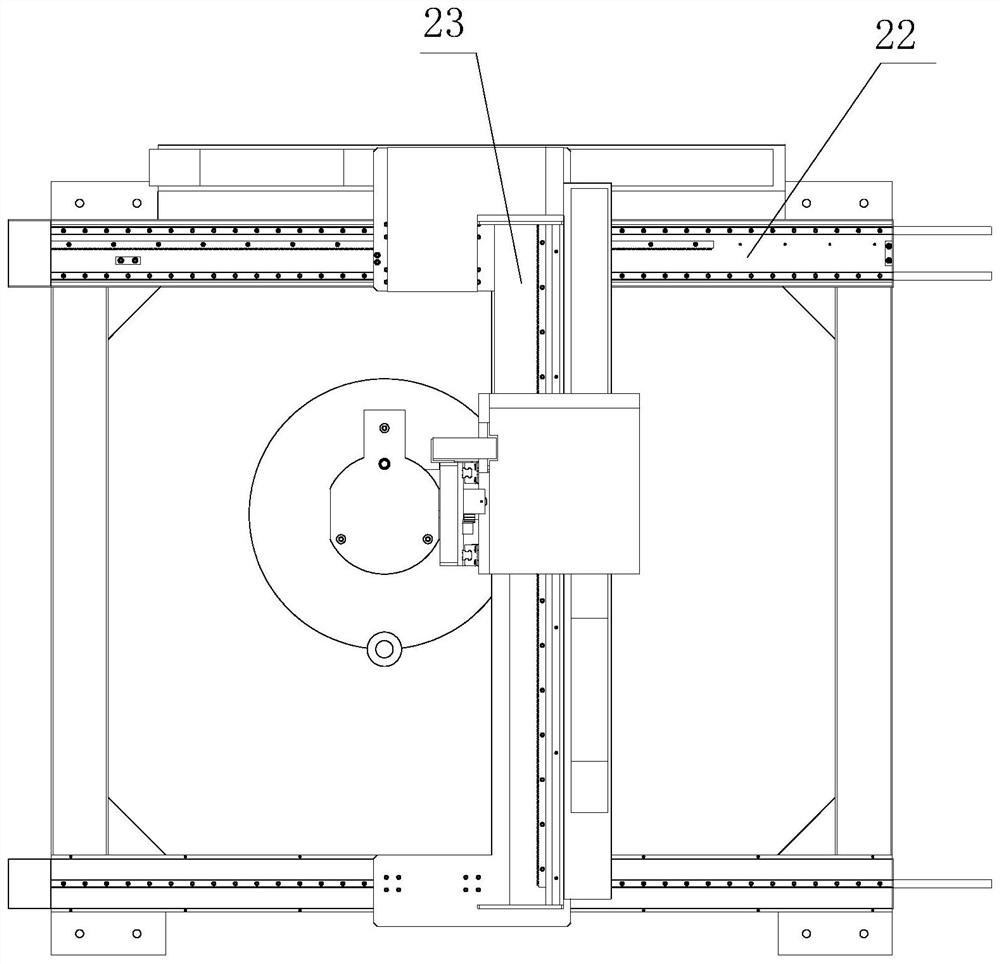

[0068] Example 1, see Figure 1 to Figure 7 , the first embodiment of the present invention provides a vehicle automatic identification oil filling system, including:

[0069] The oil injection pipe lifting assembly drives the oil injection pipe 6 up and down to inject oil into the vehicle through the vehicle oil injection port;

[0070] The fuel injection port position identification component 1 is used to identify the position of the fuel injection port of the vehicle and obtain imaging information;

[0071] The three-axis moving assembly 2 drives the oil injection pipe lifting assembly and the oil injection port position identification assembly 1 to move together;

[0072] And a microprocessor, which receives data information, analyzes and controls each component to perform corresponding operations;

[0073] The output end of the oil filling pipe lifting assembly is connected to the input end of the microprocessor, the output end of the oil filling port position identific...

Embodiment 2

[0093] Embodiment 2, the second embodiment of the present invention provides an automatic oil filling method for a vehicle, including the following steps:

[0094] (1) After driving the vehicle to the refueling area, stop and turn off the engine, the vehicle identification component identifies the vehicle and obtains the vehicle identification information, and the vehicle identification component sends the vehicle identification information to the microprocessor;

[0095] (2) the microprocessor receives the vehicle identification information from the vehicle identification component, and stores the vehicle identification information in the storage module;

[0096] (3) The oil filling port position identification component 1 identifies the position of the vehicle oil filling port, obtains imaging information, and sends the imaging information to the microprocessor;

[0097] (4) The microprocessor receives the imaging information and processes the imaging information, and the mi...

Embodiment 3

[0106] Embodiment 3, the third embodiment of the present invention further provides an automatic oil filling method for a vehicle. The structure of the third embodiment is roughly the same as that of the second embodiment. The difference is that in this embodiment, during oil filling, the The processor controls the intermittent rotation of the servo motor 7 through the oil injection pipe control component to realize the intermittent rise of the oil injection pipe 6; that is, when the distance h between the oil injection pipe 6 and the oil level is h 1 When ≤10mm, the microprocessor controls the oil injection pipe 6 to rise by 90mm through the oil injection pipe control assembly, and repeats the rising process to realize the intermittent rise of the oil injection pipe 6 .

[0107] The implementation principle and the technical effect produced by the third embodiment of the present invention are the same as those in the second embodiment. For the sake of brief description, for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com