Rotary drilling rig construction pile foundation structure and construction method thereof

A technology of rotary drilling rigs and construction piles, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as reinforcement cages floating, partitions being jacked up by reinforcement cages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

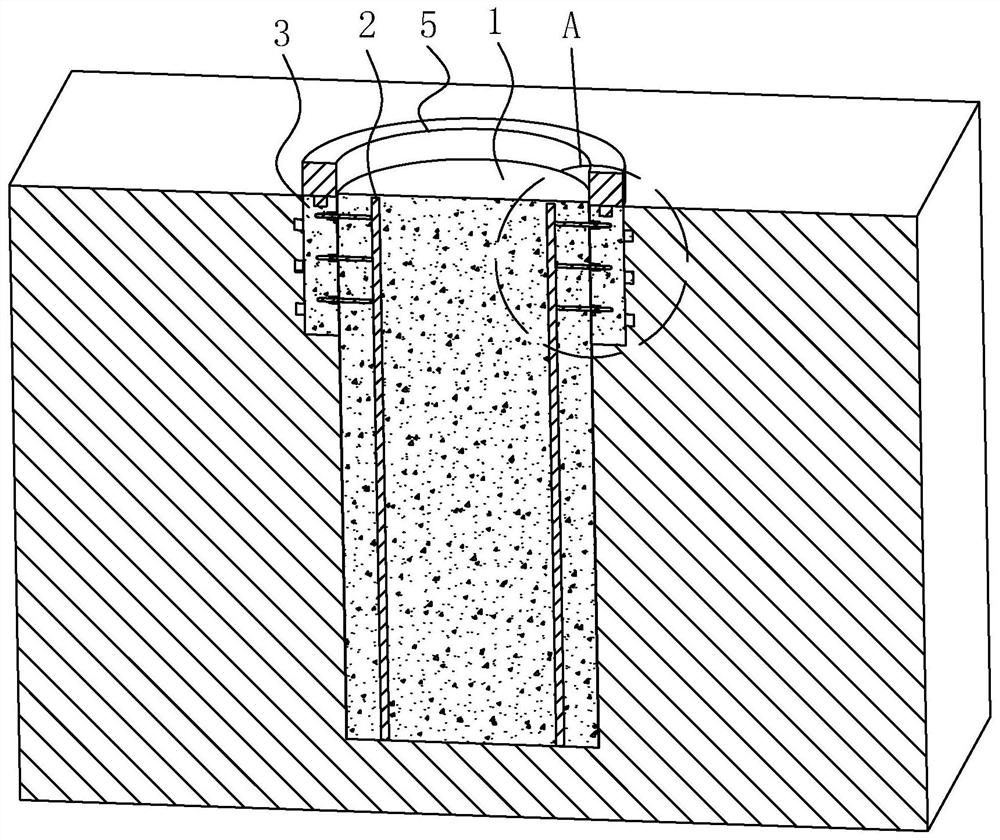

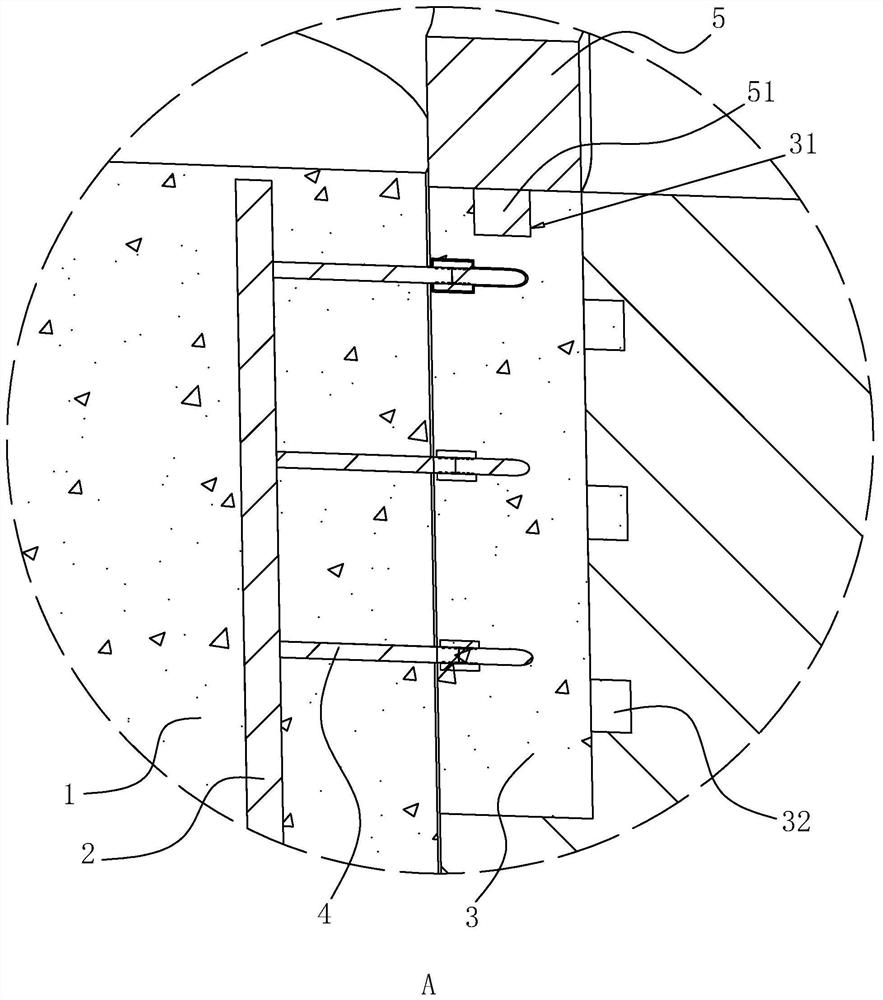

[0038] The following is attached Figure 1-4 The application is described in further detail.

[0039] The embodiment of the present application discloses a pile foundation structure constructed by a rotary drilling rig.

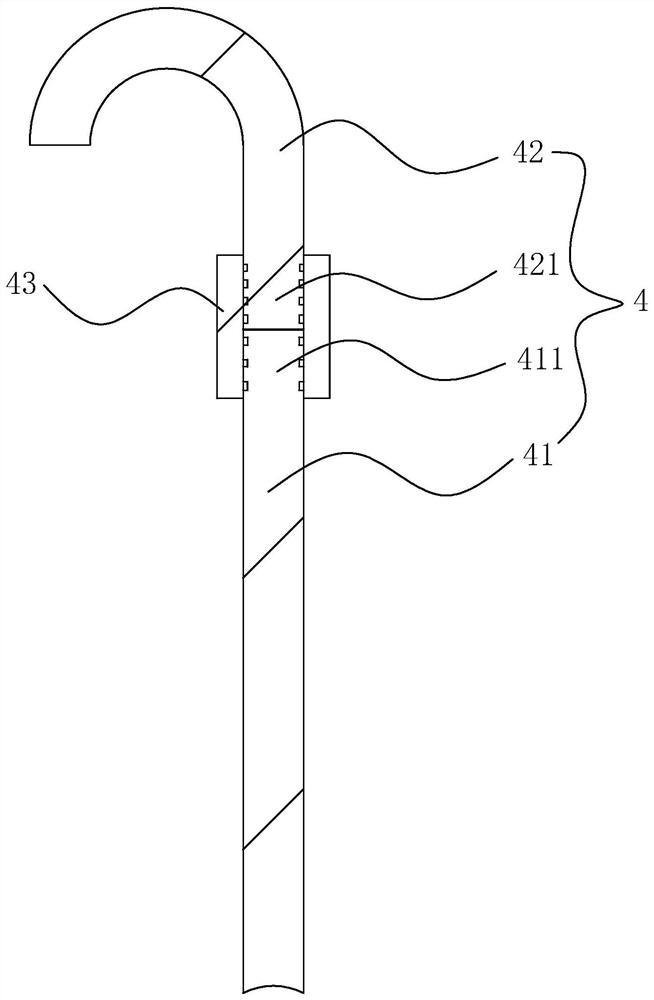

[0040] refer to figure 1 and figure 2 , a pile foundation structure constructed by a rotary drilling rig, comprising a pile body 1 along the vertical direction, the pile body 1 itself is made of concrete material, a reinforcement cage skeleton 2 is arranged inside the pile body 1, and the reinforcement cage skeleton 2 is assembled in a reinforcement field, And after the pile hole is cleared, it is hoisted into the pile hole. The reinforcement cage skeleton 2 includes a plurality of main reinforcements and a plurality of stirrups. The plurality of main reinforcements are evenly arranged along the circumferential direction, and the stirrups are welded with each main reinforcement in a ring shape; the pile body 1 and is located near the top of the pile body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com