Method for clearing wax in rod-pumped well

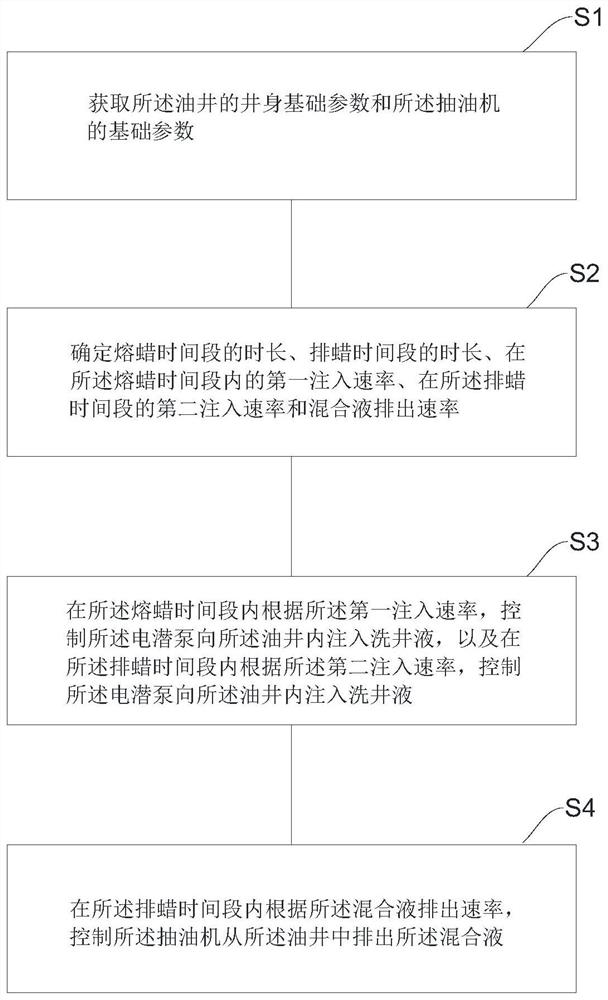

A technology of pumping wells and pumping units, which is applied in earthwork drilling, cleaning tools, wellbore/well components, etc., can solve problems such as reduced oil recovery rate, reduced oil recovery efficiency, and impact on production cycle, so as to avoid excessive injection rate. Fast or too slow, avoiding pump blockage and pump jamming, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

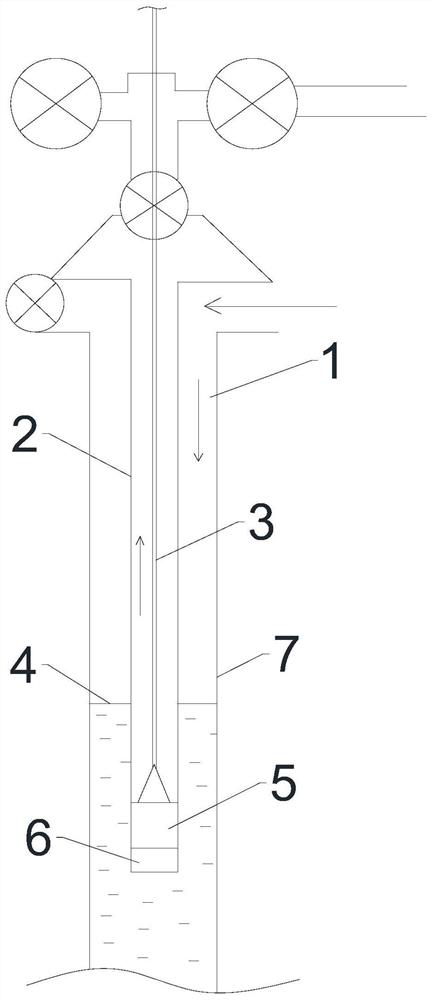

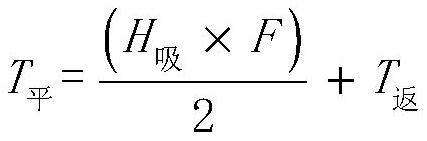

[0069] The structure of the pumping well is as figure 1 As shown, the pumping unit well includes an oil well and a pumping unit. The wellhead of the oil well is provided with an electric submersible pump, and the electric submersible pump is used to collect well-washing fluid from the formation and inject it into the oil well. The pumping unit specifically includes a casing 7, a pumping pump 5. The oil suction pipe 2 and the sucker rod 3, the oil suction pipe 2 is placed in the casing 7, the outer wall of the oil suction pipe 2 and the inner wall of the casing 7 form an oil casing annulus 1, and the oil well pump 5 is located in the casing 7, and The bottom end of the oil pipe 2 is fixedly connected, the pump inlet 6 of the oil well pump 5 faces vertically down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com