An electromechanical monitoring device

A monitoring device, electromechanical technology, applied in the direction of measuring device, measuring device casing, electronic circuit testing, etc., can solve the problems of single function, unsynchronized environment, monitoring, etc., achieve the effect of thorough monitoring, improve work efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

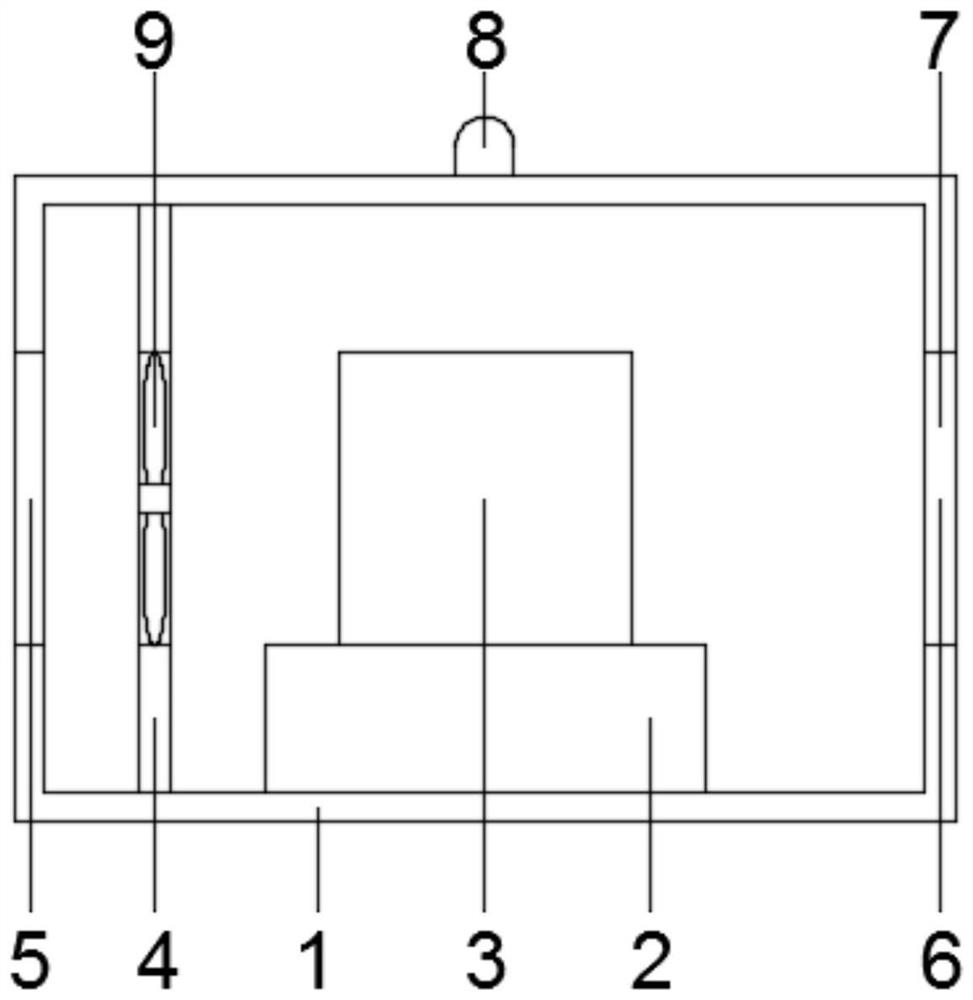

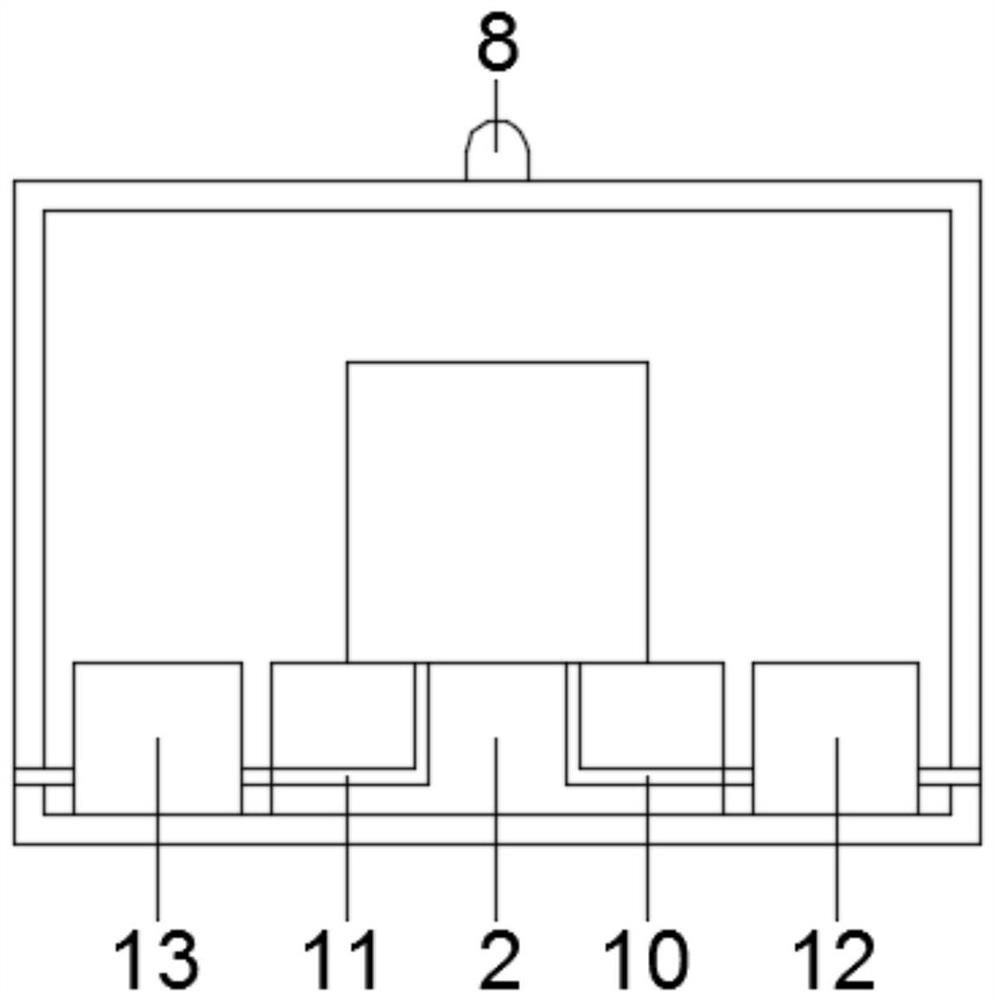

[0026] Such as Figure 1-5 The shown electromechanical monitoring device includes a monitoring box 1, and the inner side of the top of the monitoring box 1 is fixedly installed with an electromechanical base 2 for installing electromechanical equipment 3, which is preferably clamped for easy disassembly. At the same time, the monitoring box 1 is preferably The existing structure with a cover is convenient for operations such as maintenance of the switch; a fixed frame 4 fixedly connected to the monitoring box 1 is installed on one side of the electromechanical device 3, and a fan 9 is installed on the fixed frame 4, that is, by setting the fan 9. Air-cool the electromechanical equipment 3 to dissipate heat when it is necessary to prevent long-term working temperature. A filter mechanism 7 is installed in the air outlet hole 6 and the air inlet hole 5, that is, when heat is dissipated, by the action of the blower fan 9, the external wind enters the inside of the monitoring box ...

Embodiment 2

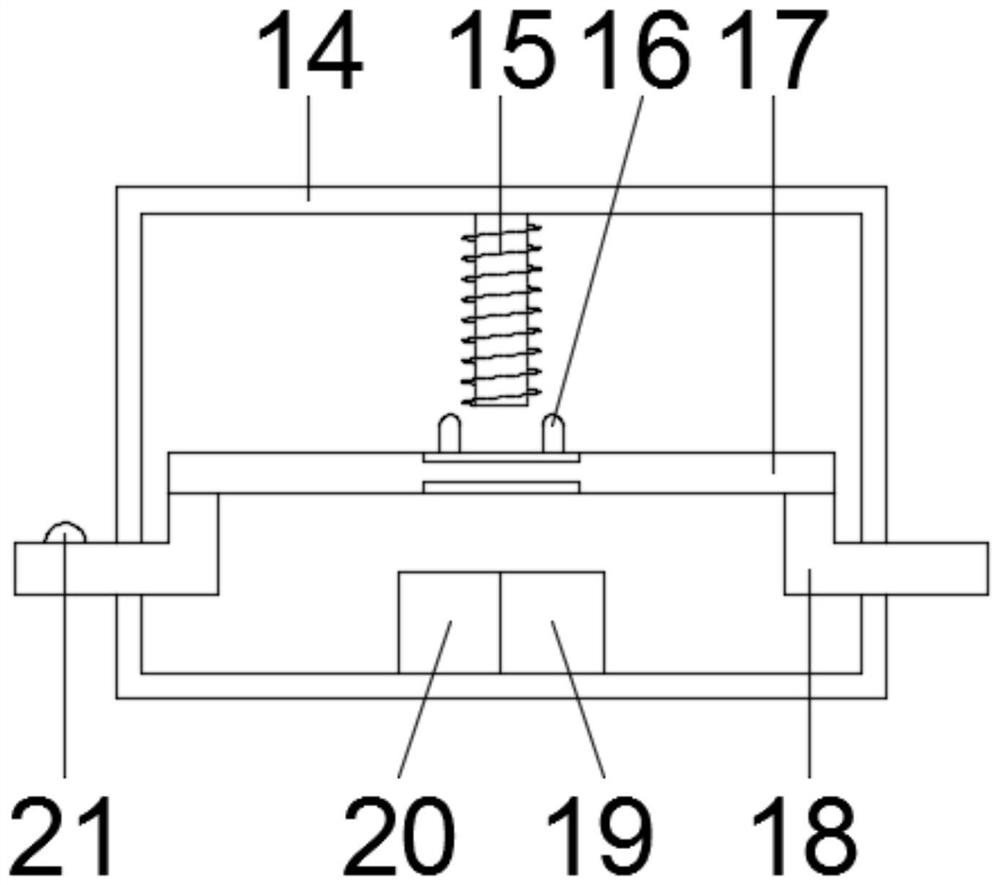

[0031] This embodiment is further optimized on the basis of embodiment 1, as Figure 6-8 As shown, the filter mechanism 7 includes a first filter plate 34 and a second filter plate 37, the first filter plate 34 is provided with a plurality of evenly distributed first filter holes 35, and the first filter plate 34- A plurality of uniformly distributed first protrusions 36 are fixedly installed on the side, and the first protrusions 36 are set in a staggered manner with the first filter holes 35, and the second filter plate 37 is provided with a The second filter hole 38, the second filter plate 37 is fixedly installed with the second protrusion 39 matched with the first filter hole 35, preferably, the first filter plate 34 is arranged on the inner side and fixed with the monitoring box 1 , the second filter plate 37 is arranged on the outside and is slidably connected with the monitoring box body 1. During normal filtration, the second filter plate 37 is separated from the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com