A kind of optical fiber sensing device and method of shearer mechanical state

A technology of optical fiber sensing and mechanical state, which is applied in the direction of using optical devices to transmit sensing components, measuring devices, and converting sensor outputs, etc., which can solve the problem of strict requirements on the transmission mode of sensing signals, limited sensing data transmission capacity, and shaft modules. Problems such as volume and mass increase, to avoid explosion-proof design and anti-electromagnetic interference design, reduce transmission capacity limitations, and achieve the effects of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

[0041] Among them, the present invention is attached figure 1 as a basis, with figure 1 The left, right, up, down, center, and focus of the present invention are left, right, up, down, center, and focus. It should be noted that the relative arrangement, numerical values, etc. of components set forth in the present embodiment are not limited to the scope of the present invention unless specifically stated otherwise.

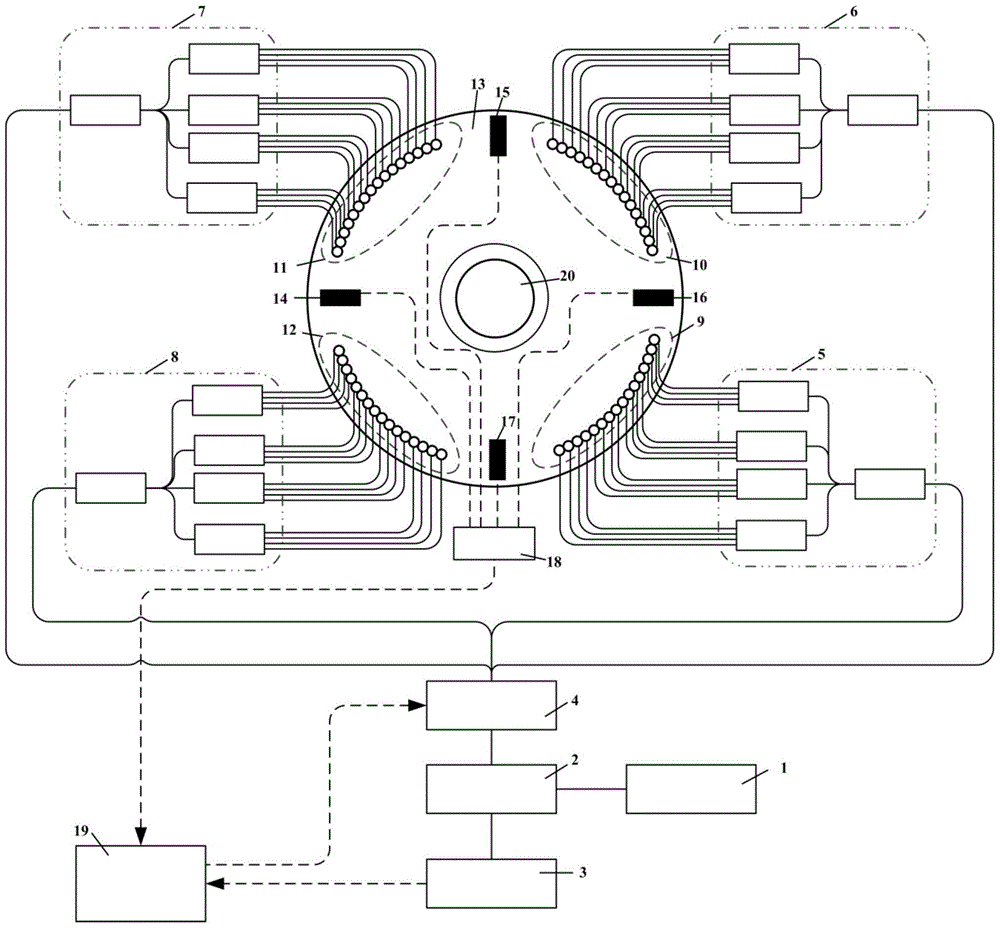

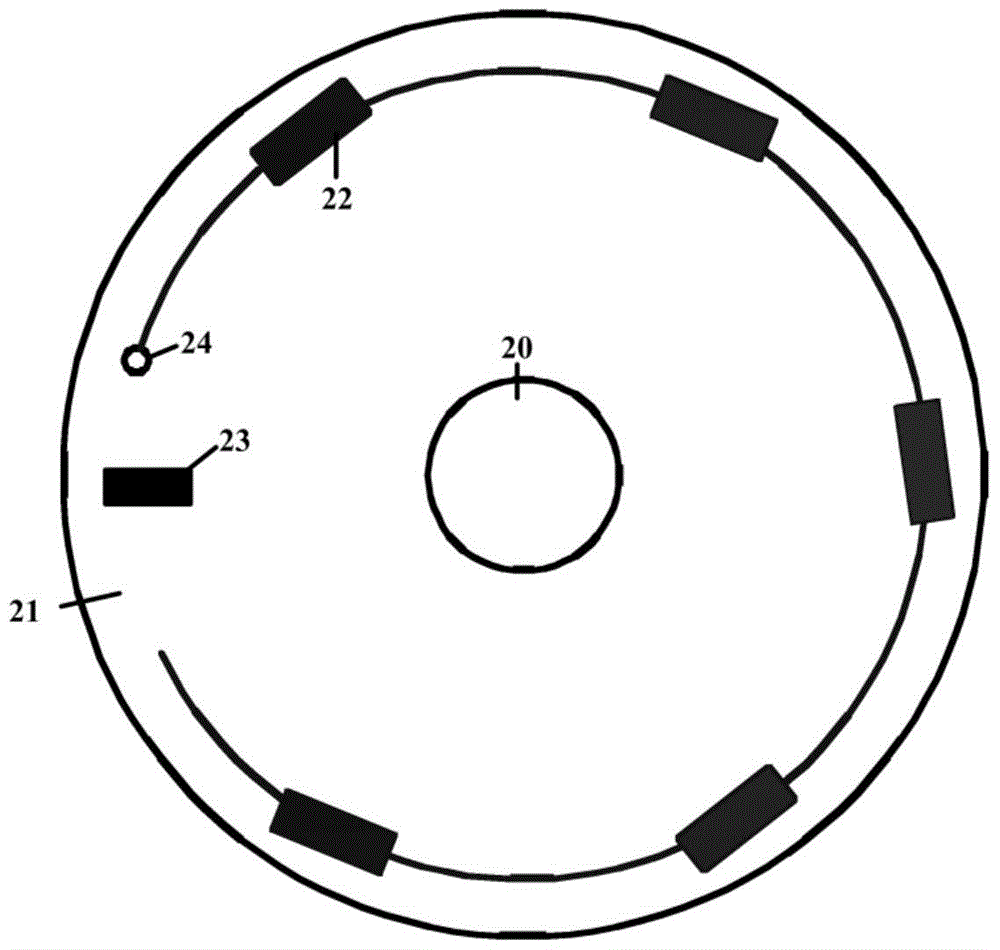

[0042] Such as figure 1 and figure 2 Shown: an optical fiber sensing device for the mechanical state of a coal mining machine, which includes:

[0043] Broadband light source 1, 2×1 fiber coupler 2, fiber grating demodulation module 3, 1×4 optical switch 4, fiber coupler cluster I5, fiber coupler cluster II6, fiber coupler cluster III7, fiber coupler cluster IV8, Collimating lens group Ⅰ9, collimating lens group Ⅱ10, collimating lens group Ⅲ11, collimatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com