Hang tag stringing device and method

A hanging tag and rope-threading technology, which is applied in packaging, transportation, packaging, labeling, etc., can solve problems such as difficult production efficiency, labor-intensive, error-prone, etc., and achieve the effect of improving production efficiency and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

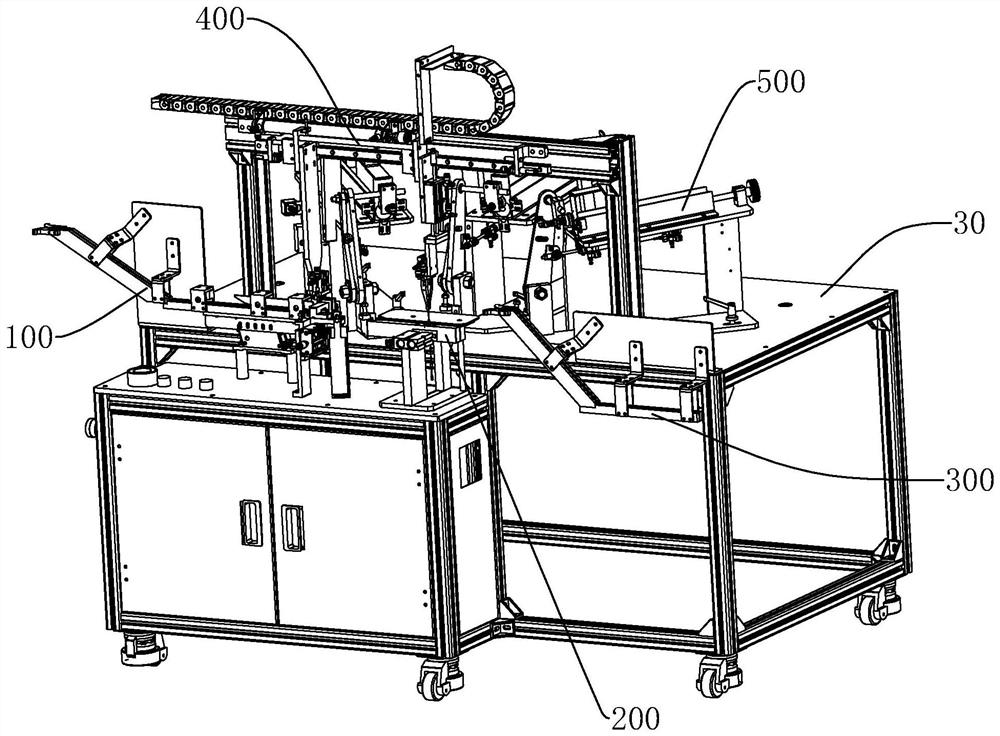

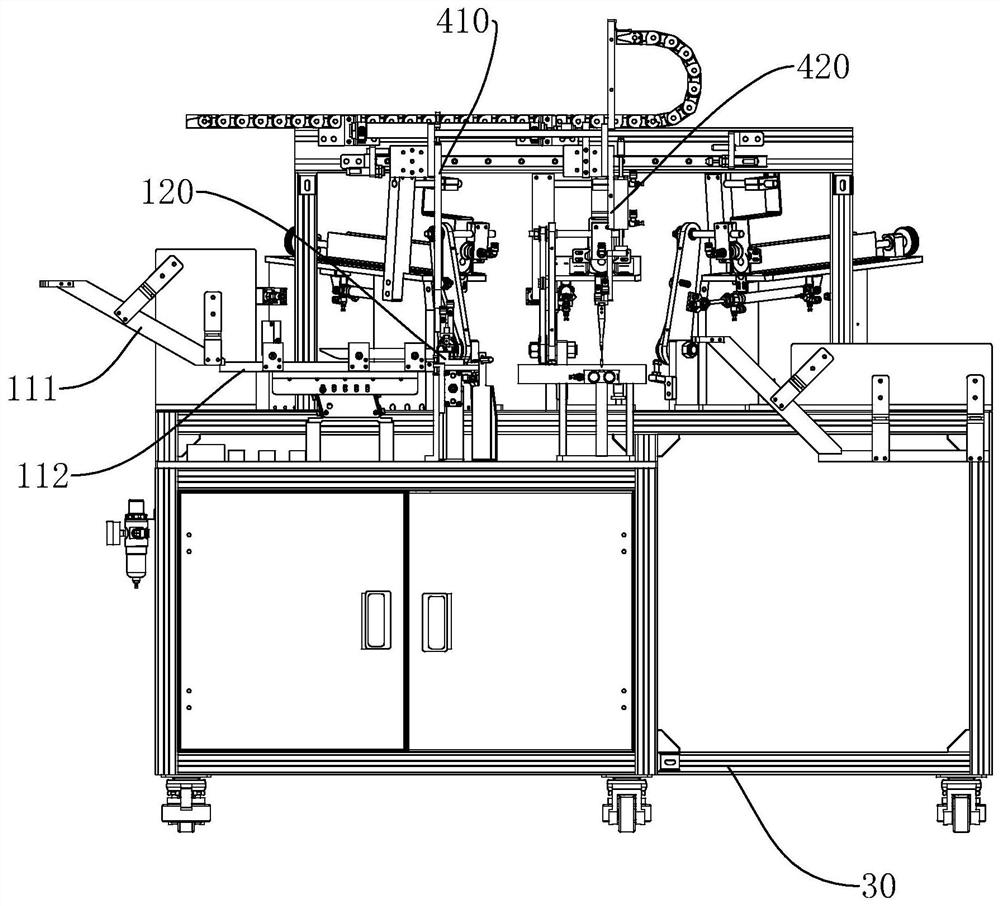

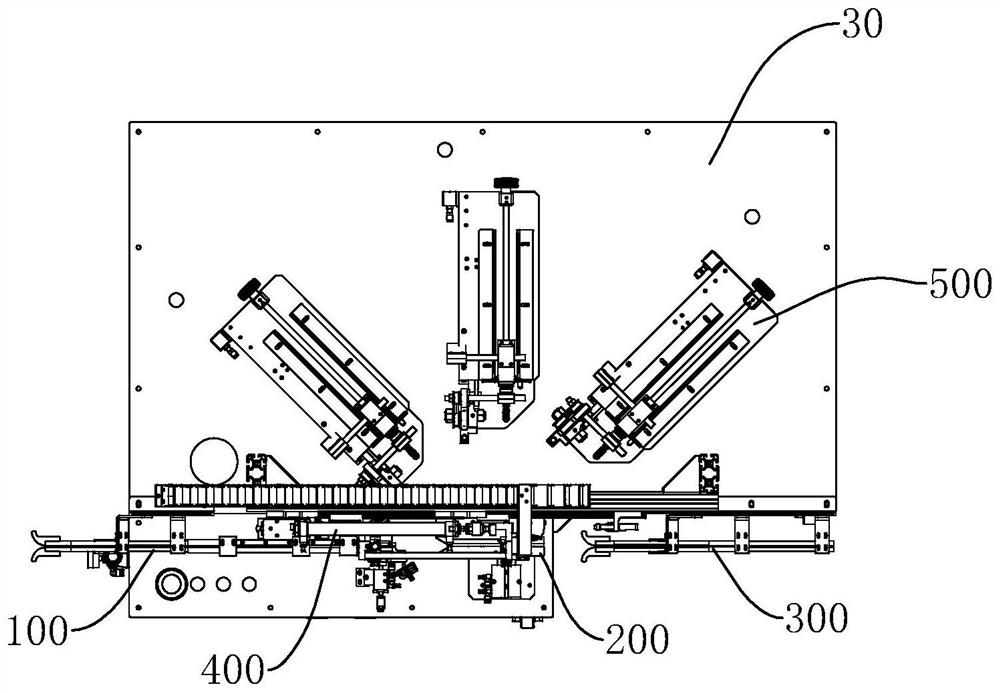

[0027] Such as Figure 1 to Figure 10 As shown, the present embodiment provides a hanging tag threading device, which is used for threading at least one hanging tag 10 into a hanging rope 20. The hanging rope 20 includes a rope 21 and first ends 22 and The size of the first end 22 is smaller than that of the second end 23 . The first end 22 and the second end 23 can be fastened to each other, for example, the two ends of the lanyard 20 can be fastened together, and the first end 22 can be inserted into the second end 23 to achieve fastening, or Other existing methods can be used, as long as the lanyard 20 can be hung on the clothing. The hang tag 10 has a through hole, the size of which is between the size of the first end 22 and the size of the second end 23, so that when the lanyard 20 is in the vertical state with the first end 22 on the top and the second end 23 on the bottom , the hanging tag 10 can pass through the first end 22 and be stuck on the second end 23 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com