Prefabricated double-T plate end connecting structure and construction method thereof

A technology for connecting structures and plate ends, which is applied to floors, building components, building structures, etc., can solve the problems of low connection safety, waste of materials, and increase the weight of the structure, so as to save materials, facilitate construction, and reduce the weight of the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

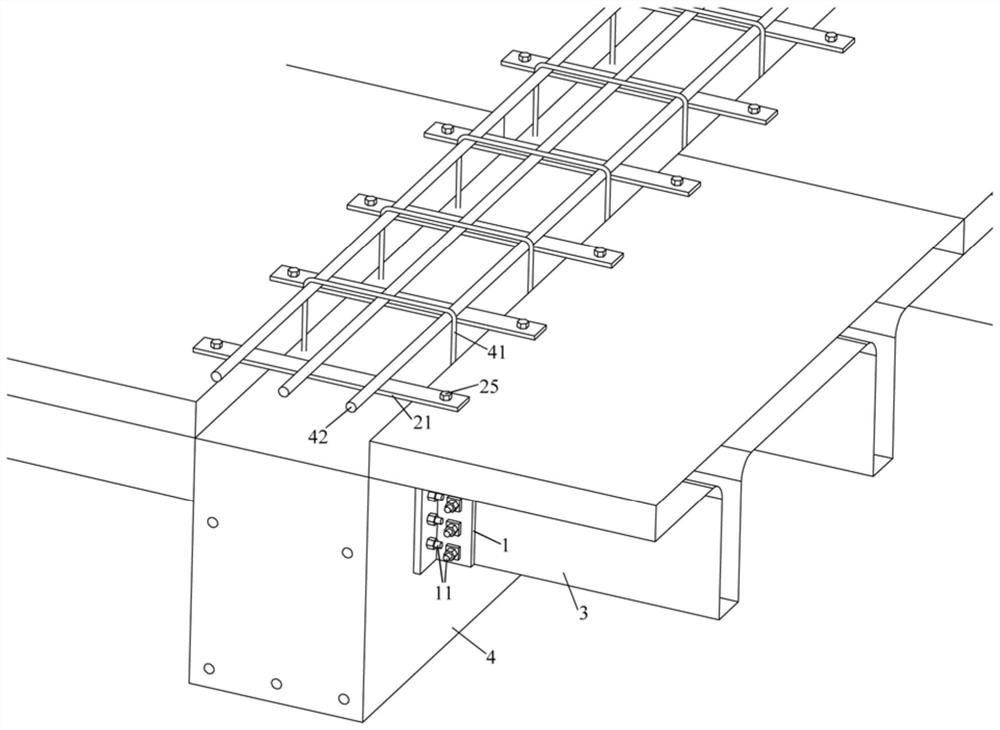

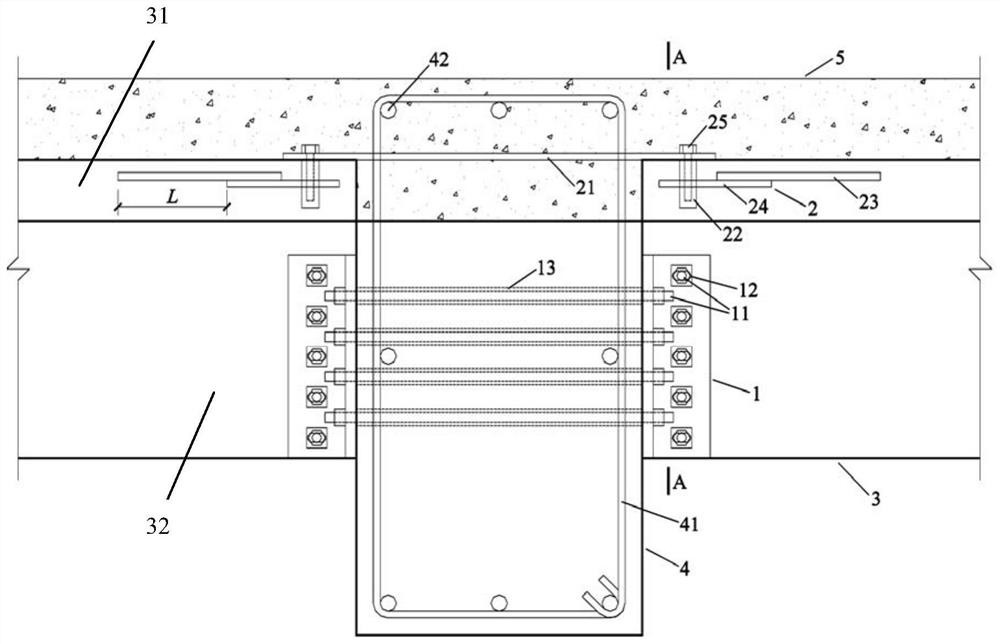

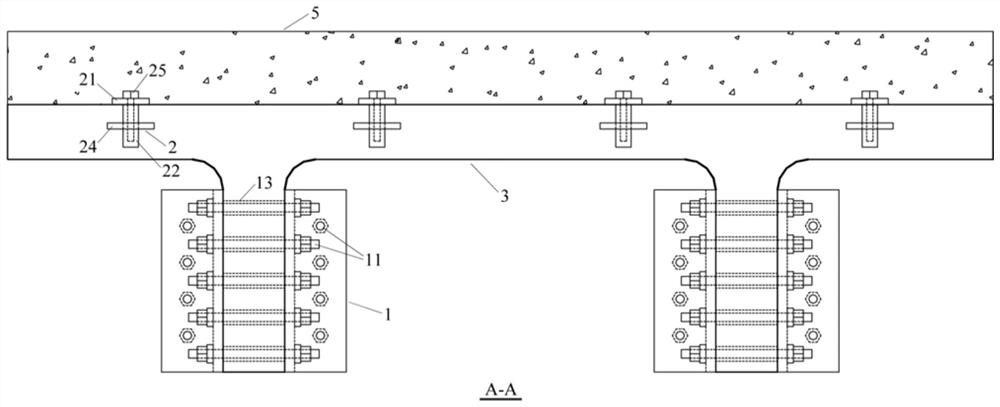

[0038] combine Figure 1 to Figure 5 , the present invention provides a prefabricated double T-plate end connection structure, comprising a group of multiple connecting steel plates 21 for bridging, the two ends of the connecting steel plates are provided with positioning connection holes, and the connecting steel plates 21 are fastened by fixing bolts 25 The two sides are respectively connected and fixed to the internally threaded h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com