Posttensioning method for pretensioning of heavy prestressed structures

A technology of prestressed structure and post-tensioning method, which is applied in the field of pretensioning construction, can solve problems such as excessive overtension load, engineering difficulty, collapse, etc., and achieve the effect of easy realization and avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

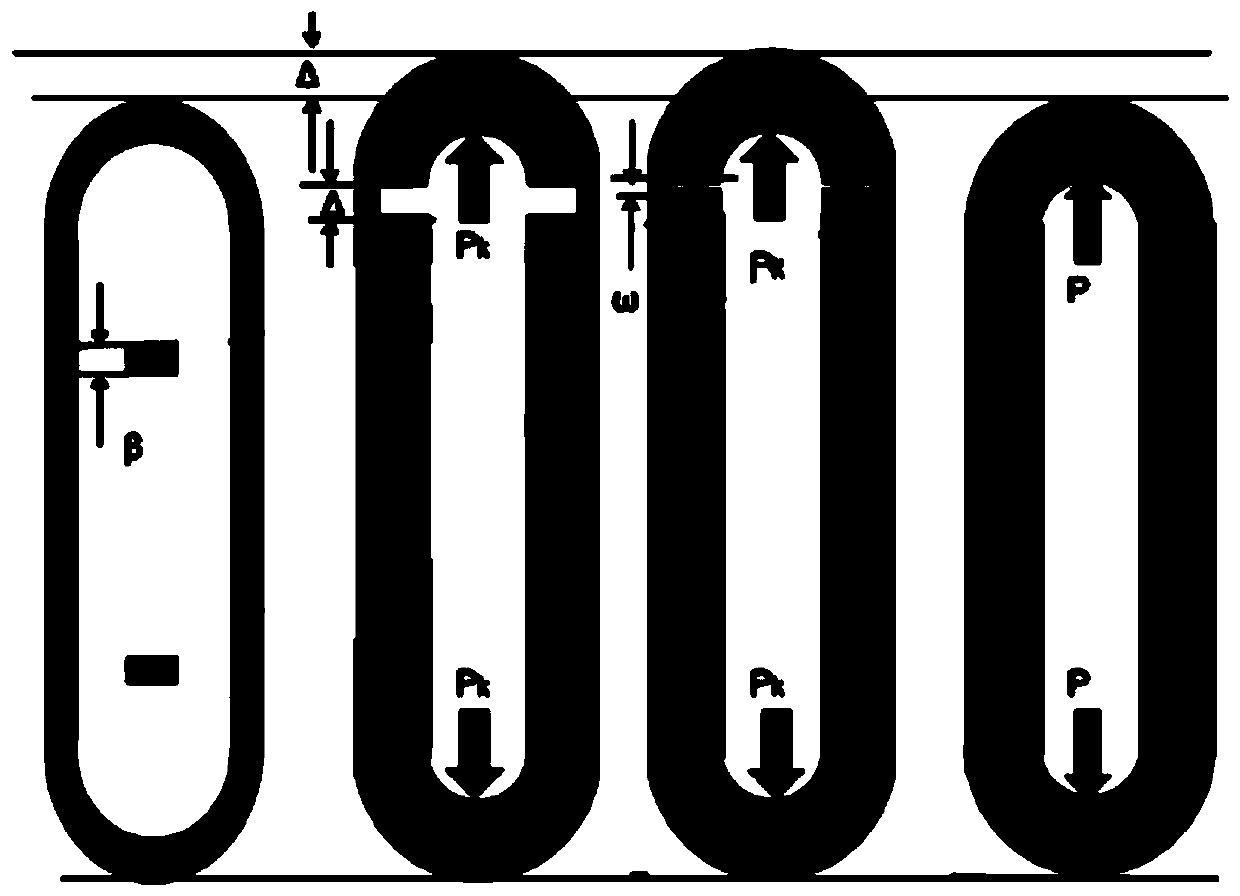

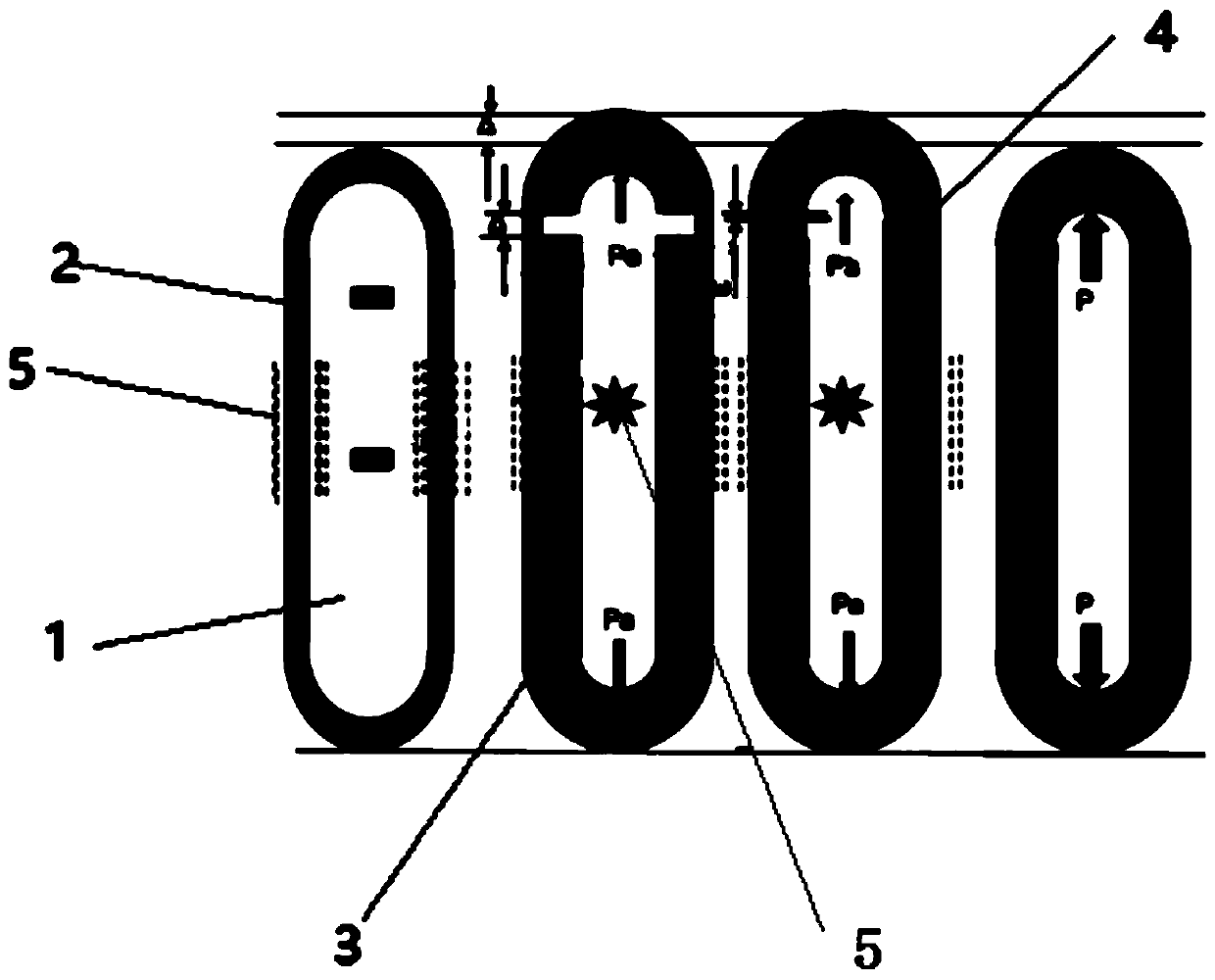

[0039] Embodiment: A kind of post-tensioning method that is used for the pretensioning of heavy-duty prestressed structure, concrete steps are as follows:

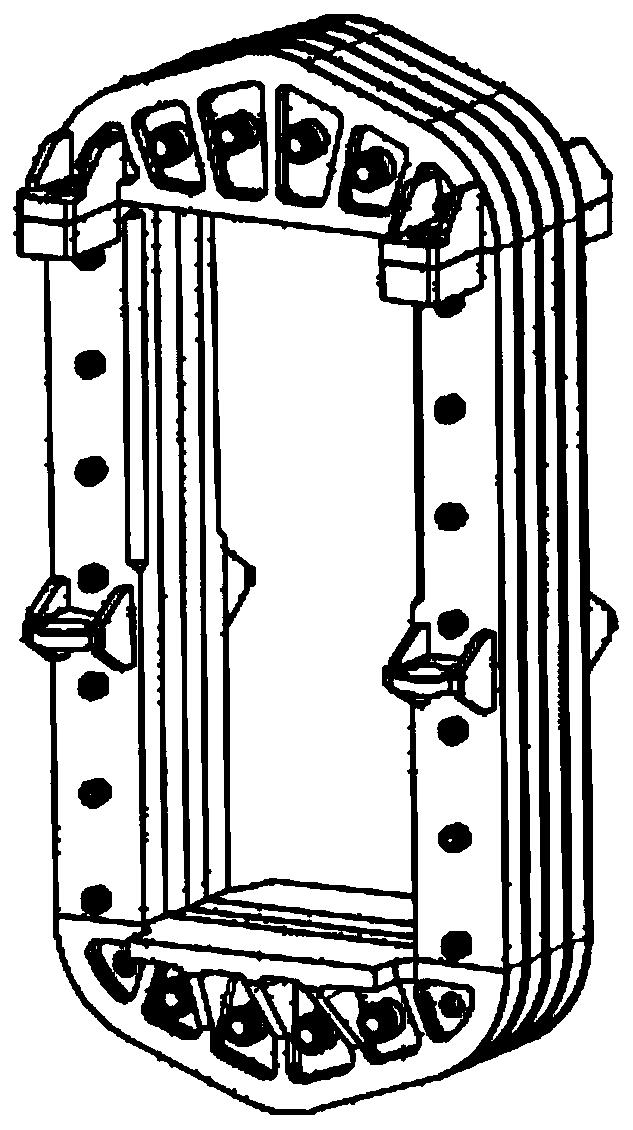

[0040] Step 1: Making the mold 1, the size of the mold 1 is consistent with the final size after the pretension of the winding structure to be pretensioned;

[0041] Step 2: winding the steel wire layer on the mold 1, and then removing the steel wire layer from the mold 1 to obtain a complete tension-free steel wire circle 2;

[0042] Step 3: using the heating device 5 to heat the steel wire layer ring 2 to make it expand when heated;

[0043] Step 4: Put the steel wire layer ring 2 on the outside of the winding structure 3 to be pre-tightened;

[0044] Step 5: continue to heat the steel wire layer coil 2 set on the winding structure to be pre-tightened;

[0045] Step 6: Apply an auxiliary load Pa to the movable end of the winding structure 3 to be pre-tightened, so that the movable end of the winding structure 3 to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com