Contact bounce analysis method for multi-flexible electric appliance contact spring system

A technology of multi-flexible electrical appliances and analysis methods, which is applied in the fields of instruments, electrical digital data processing, and special data processing applications, etc. It can solve complex structure design, difficulties in dynamic analysis and prediction of contact bounce, and inability to clearly reveal the mechanism of contact bounce, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] 1. Computing power

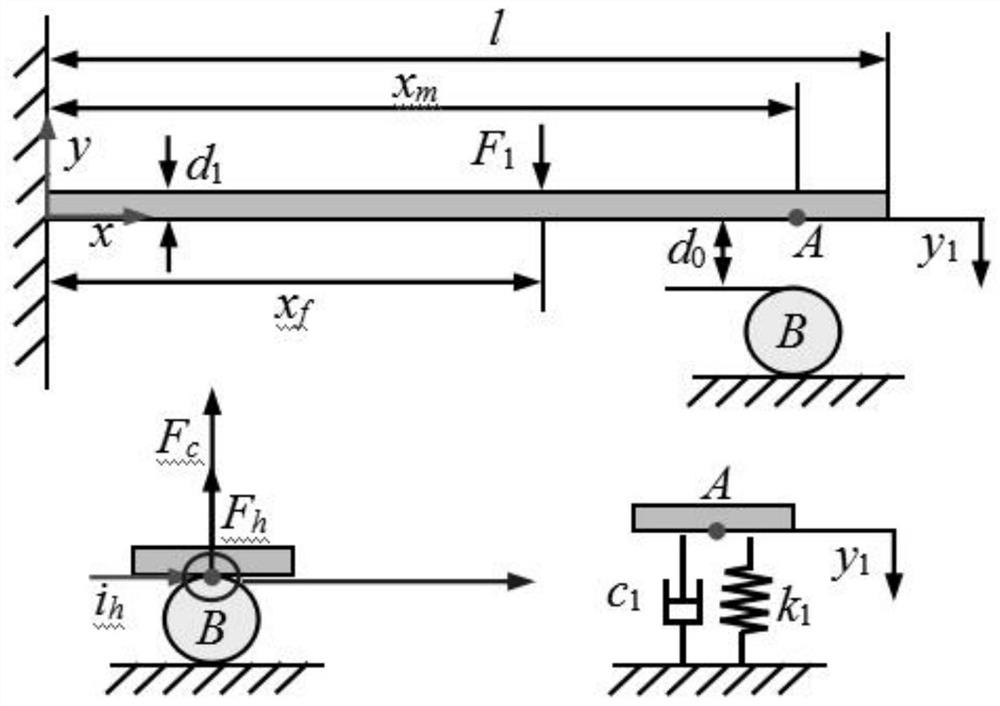

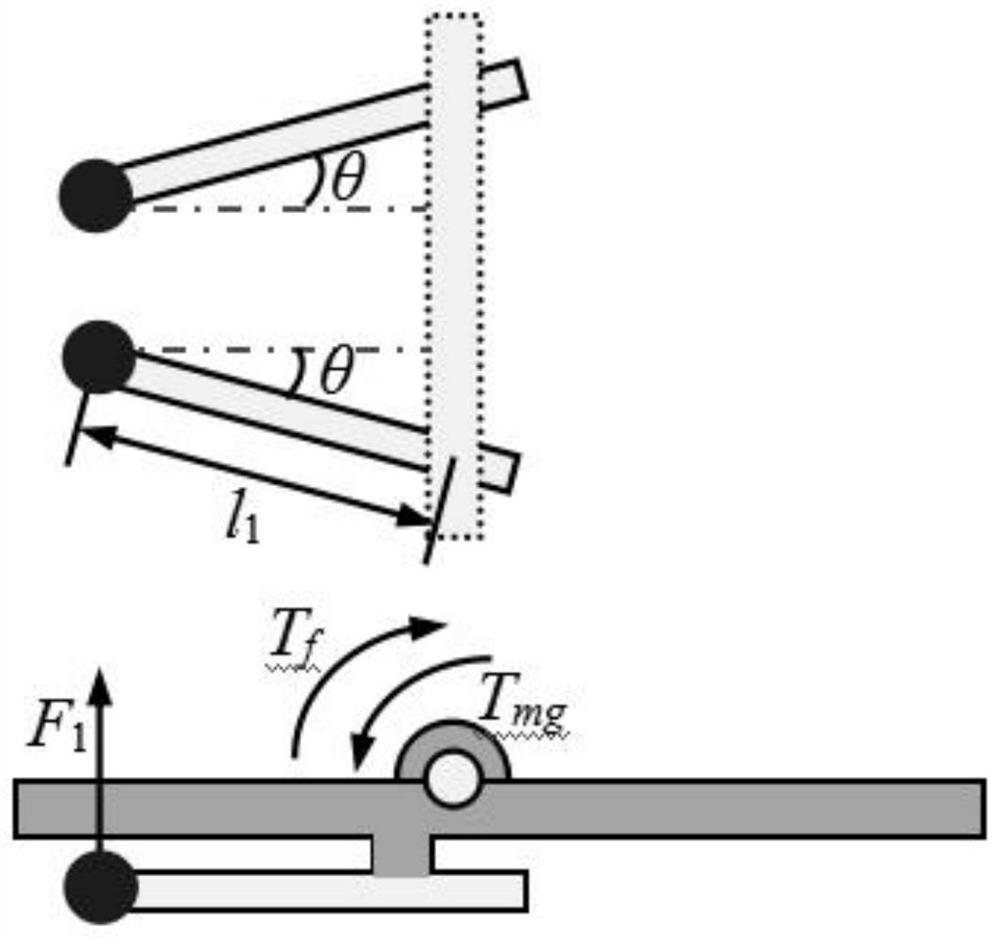

[0105] Take a certain type of relay as an example ( Figure 5 ), utilize the method of the present invention to carry out action process simulation and bounce characteristic analysis to it. Relay related parameters are: u=27V, R=1560Ω, E=1.08×10 5 N / mm 2 , α=6°, R c =94.7mΩ, ρ=1.18×10 -5 kg / mm 3 , k=1×10 5 N / mm, d 1 =0.4mm, l=4.9mm, n=1.5, d 0 = 0.09 mm.

[0106] 2. Calculation process

[0107] (1) Complete the equivalent collision dynamics model of the relay contact spring system based on step 1;

[0108] (2) Deriving relay kinematics and collision dynamics differential equations according to step 2;

[0109] (3) Utilize step 3 to set up the moving reed displacement equation of relay;

[0110] (4) complete the matrix form of the kinetic equation of relay according to step 4;

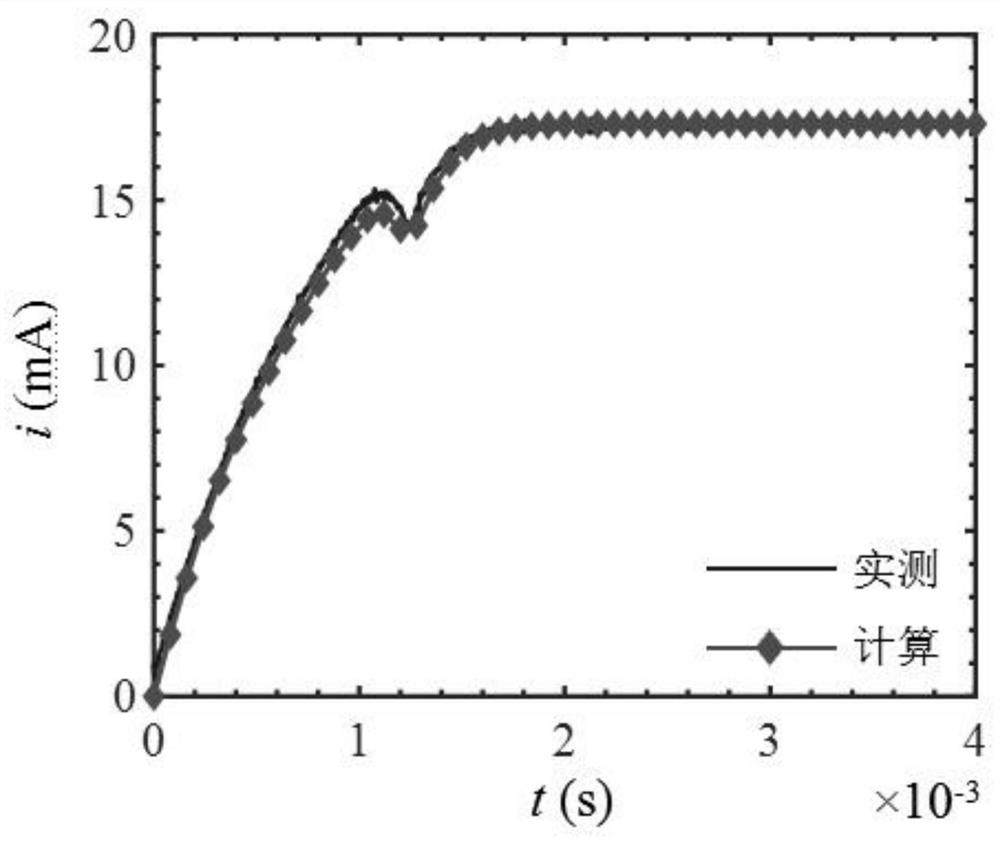

[0111] (5) Solve the matrix form of the dynamic equation of the relay in formula (4) based on the 4th-order Runge-Kutta method. Among them, the calculated sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com