Automatic leveling mechanism for square cabin

An automatic leveling and hydraulic mechanism technology, applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., can solve the problems that cannot be used anytime and anywhere, and the practicability of the shelter is low, so as to achieve convenient transportation and portability, convenient and fast use, The effect of improving usage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

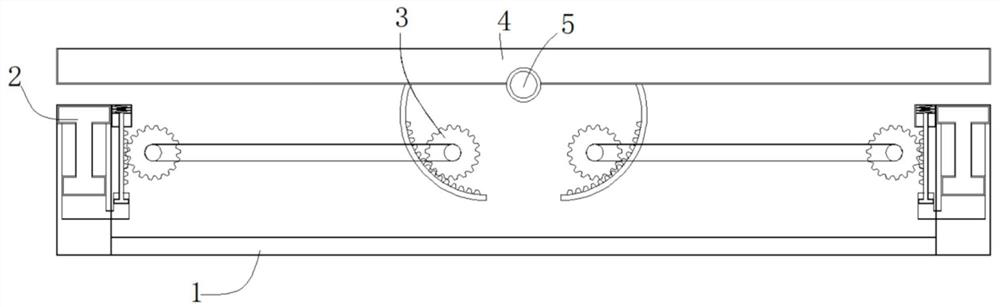

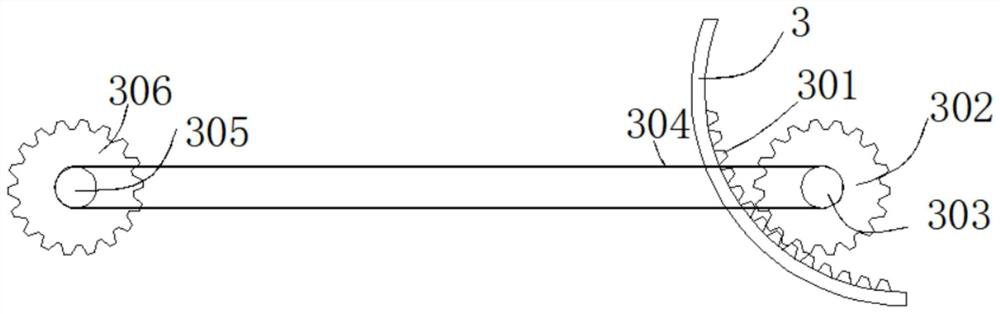

[0023] An automatic leveling mechanism for a shelter, comprising a body 1, a hydraulic mechanism 2 is fixedly connected to the side of the body 1, a concave rotating shaft 5 is fixedly connected to the top of the body 1, the number of the hydraulic mechanisms 2 is two groups, and the hydraulic mechanism 2 is The front center line of the rotating shaft 5 is a symmetrical axis fixedly installed on the side of the body 1, the top of the concave rotating shaft 5 is rotatably connected with a balance plate 4, the length of the balance plate 4 is consistent with the length of the body 1, and the middle part of the body is fixedly connected with a mechanical The transmission mechanism 3, the quantity of the mechanical transmission structure 3 is two groups.

Embodiment 2

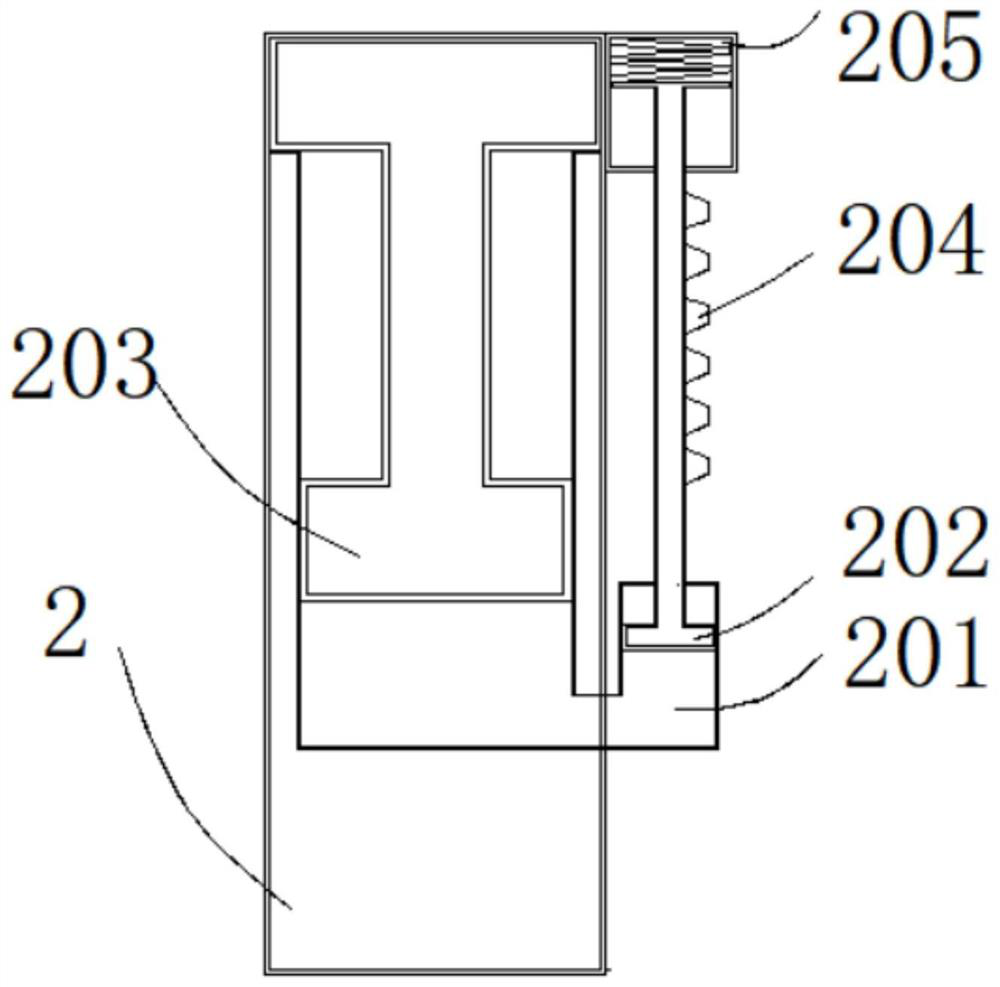

[0025] An automatic leveling mechanism for a shelter, including a body 1, the side of the body 1 is fixedly connected with a hydraulic mechanism 2, the number of the hydraulic mechanisms 2 is two groups, and the hydraulic mechanisms 2 are fixed and installed with the front centerline of the rotating shaft 5 as the symmetrical axis On the side of the body 1, the top of the concave rotating shaft 5 is rotatably connected with a balance plate 4, the length of the balance plate 4 is consistent with the length of the body 1, the middle part of the body is fixedly connected with a mechanical transmission mechanism 3, and the number of the mechanical transmission structures 3 is two. The hydraulic mechanism 2 includes a fuel tank 201, a No. 1 hydraulic valve 203 is socketed on the left side of the fuel tank 201, a No. 2 hydraulic valve 202 is socketed on the right side of the fuel tank 201, and a spring device 205 is socketed on the top of the No. 2 hydraulic valve 202. The right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com