A die-fixing device used in expressway construction and building engineering construction

A technology for construction engineering and expressway, which is applied in on-site preparation of building components, construction, water supply devices, etc., can solve the problems of extrusion deformation without good support effect, affecting the drainage effect of highways, and unfavorable water output, etc. The effect of convenient construction and use, convenient transportation, and increased transportation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

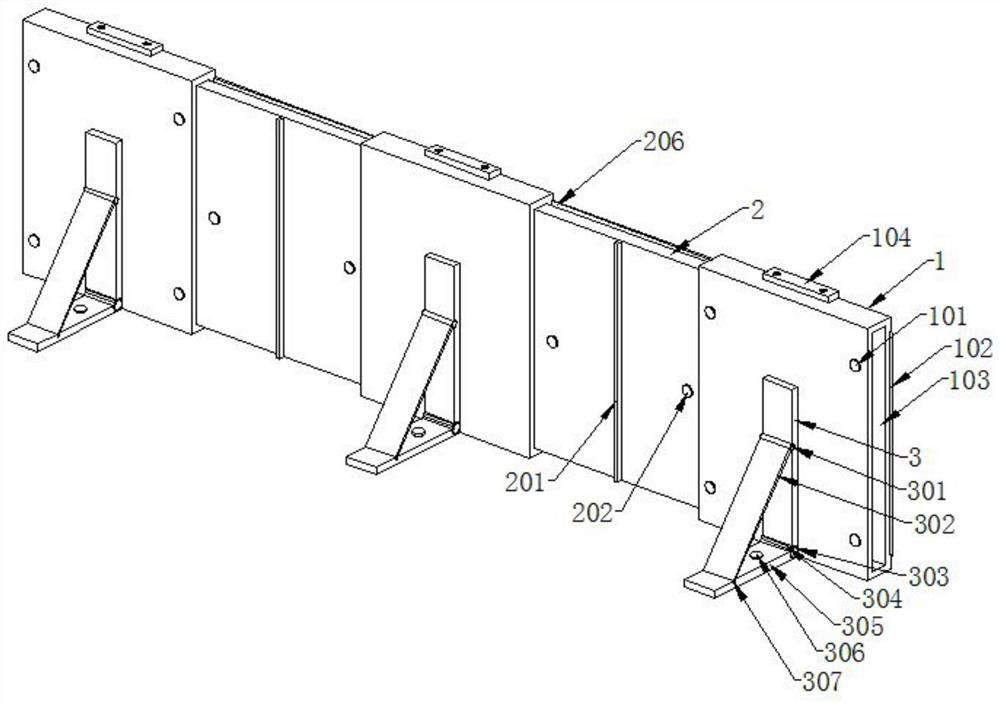

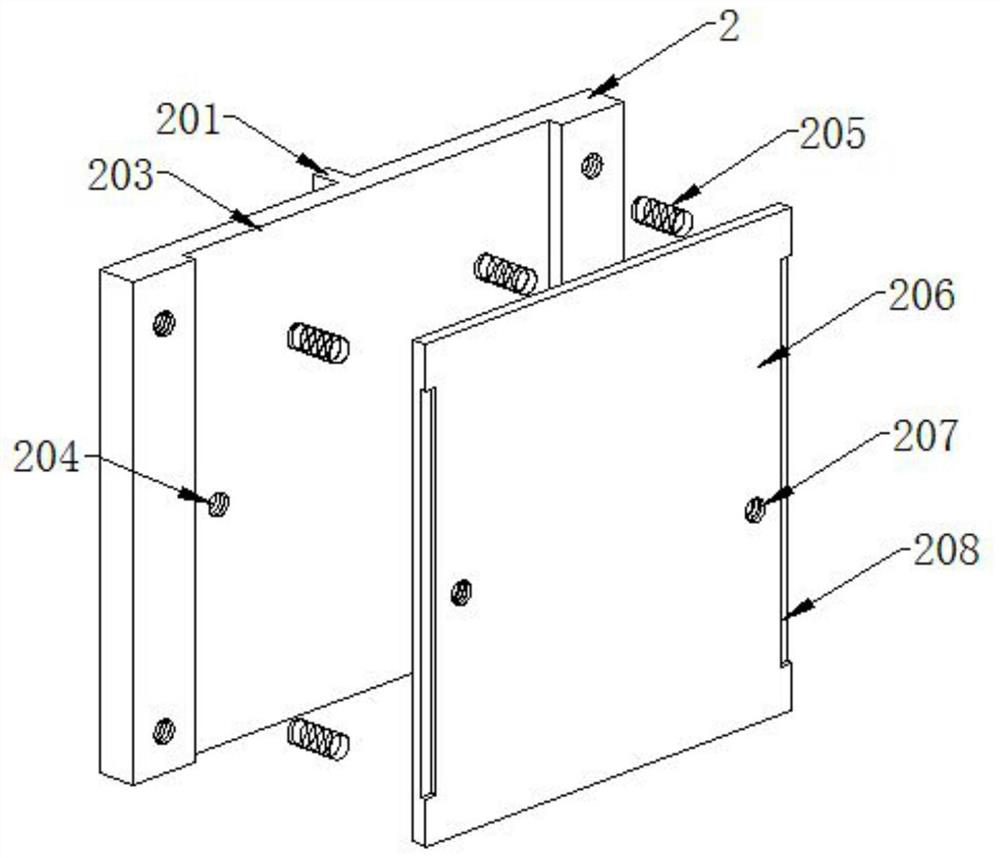

[0029] like Figure 1-6 As shown, the present invention provides a mold fixing device used in highway construction and building engineering construction, including a main fixing plate 1 and a telescopic plate 2, and a fixing bar 3 is installed in the middle of one side surface of the main fixing plate 1 A first rotating shaft 301 is installed on one side surface of the fixing bar 3, a diagonal brace 302 is installed on one end of the first rotating shaft 301, and a second rotating shaft 303 is installed on the bottom end of the fixing bar 3, The top of the second rotating shaft 303 is equipped with a limit bar 304, and one end of the second rotating shaft 303 is equipped with a bottom bar 305, and the top surface of the bottom bar 305 is provided with a hexagonal bolt 306, and the hexagonal bolt One side of 306 is provided with a groove 307, the four corners of one side surface of the main fixing plate 1 are provided with first fixing bolts 101, and the middle of both ends of ...

Embodiment 2

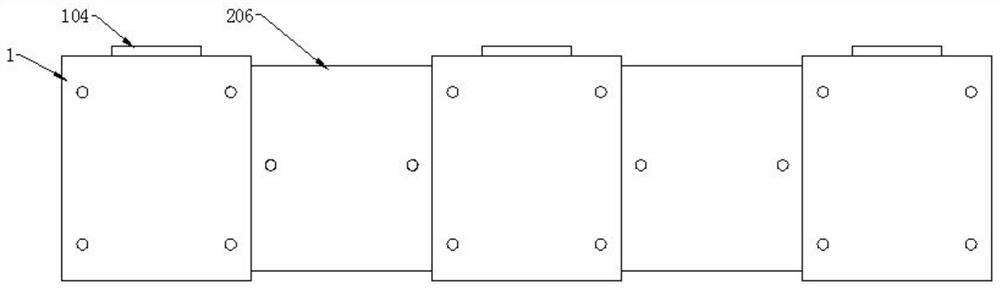

[0041] like Figure 7 As shown in the figure, if the arc-shaped template needs to be supported, the main fixing plate 1 can be directly placed at the target position, and then the two ends of the telescopic plate 2 can be placed inside the chute 103, so that the spring plate 206 is still exposed to the On the outside, since the width of the telescopic plate 2 is smaller than the width of the chute 103, which is two-thirds of the width of the chute 103, and the extension length of the telescopic plate 2 is small, after the telescopic plate 2 and the main fixing plate 1 form an inclination angle , the two ends of the concave 203 structure of the telescopic plate 2 will be in contact with the inner two end edges of the chute 103 of the main fixing plate 1 to form a fulcrum, and the external thread hole 207 will form an inclined structure with the first fixing bolt 101. After being located in the smooth middle part of the first fixing bolt 101 and being inclined, the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com