Control method and system for simulating part performance test

A control system and control method technology, which is applied in the testing of mechanical parts, the testing of machine/structural parts, vibration testing, etc. Stable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

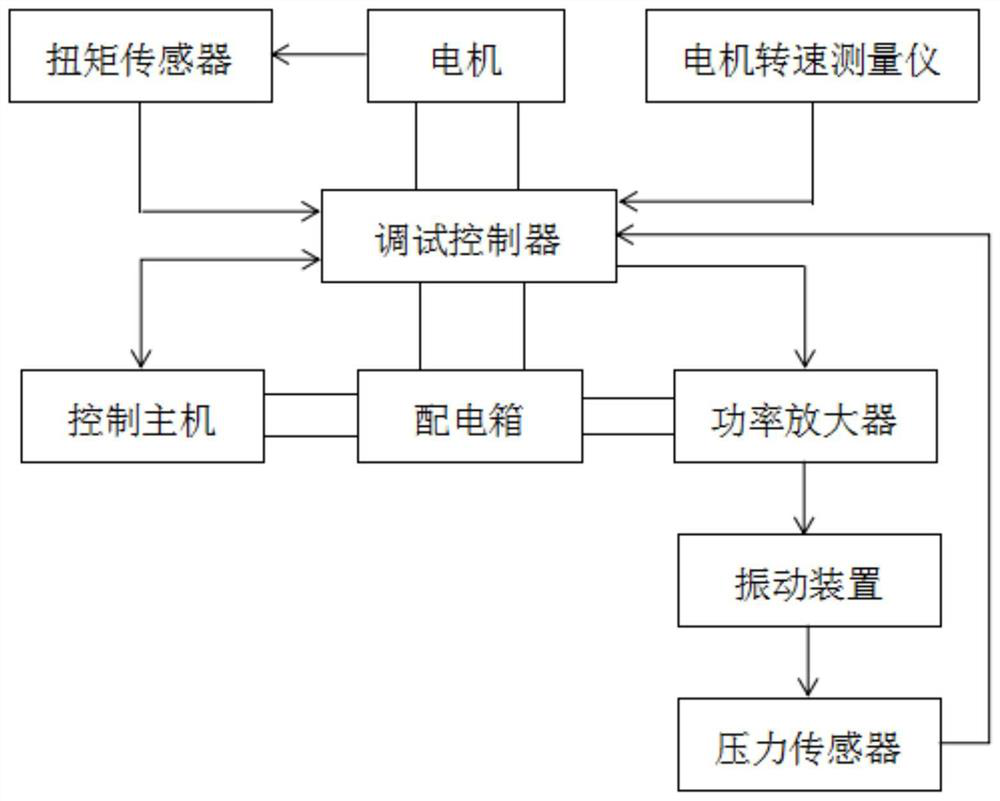

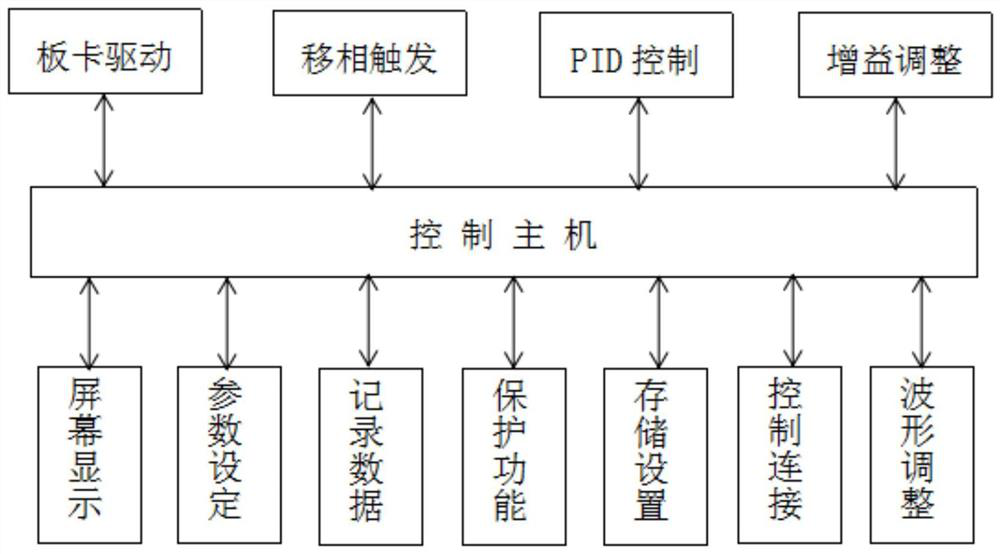

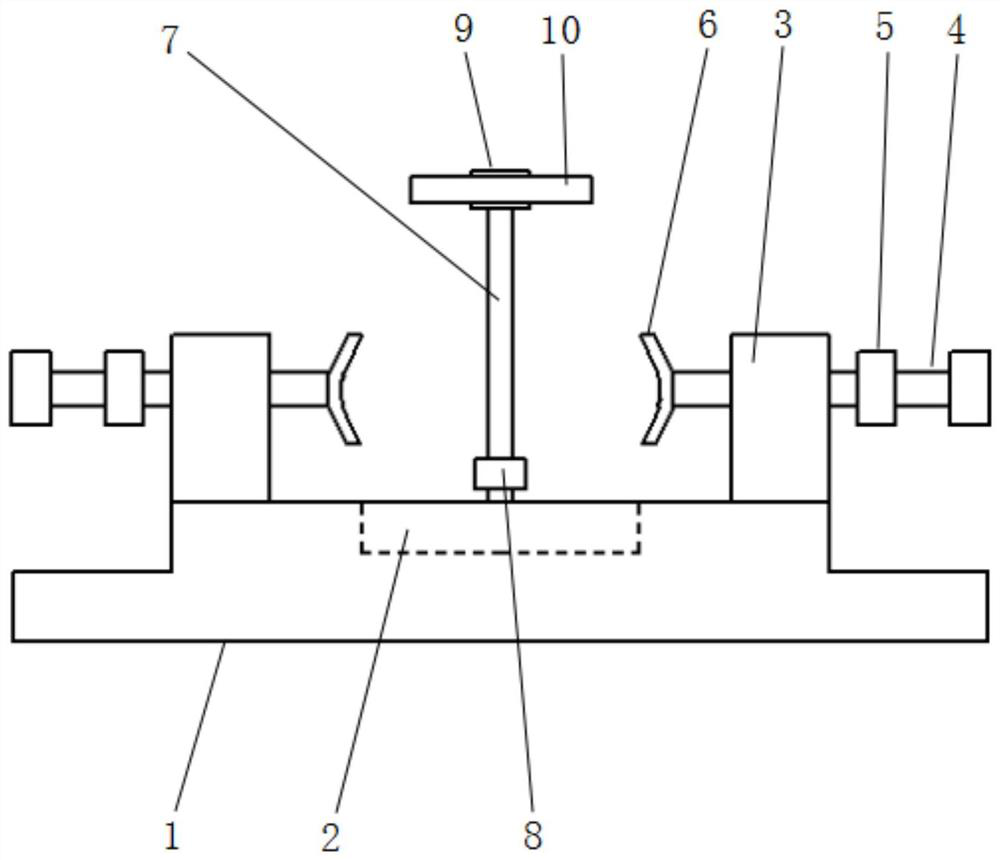

[0024] A control method for simulating part performance testing of the present invention, the method is to monitor in real time the resonant inertial force generated by the vibrating device installed with the part through the pressure sensor, and obtain the time curve of the resonant inertial force through the debugging controller , and at the same time obtain the amplitude of the resonant inertial force according to the time curve of the resonant inertial force. Then, according to the amplitude of the resonant inertial force, the vibrating device works in a resonant state consistent with the natural frequency of the control system, and the resonant inertial force amplitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com