A kind of automatic production equipment of energy-saving usb interface chip for computer

A USB interface, automatic production technology, applied in the direction of electrical components, circuits, semiconductor/solid-state device manufacturing, etc., can solve problems affecting chip production, chip tilt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

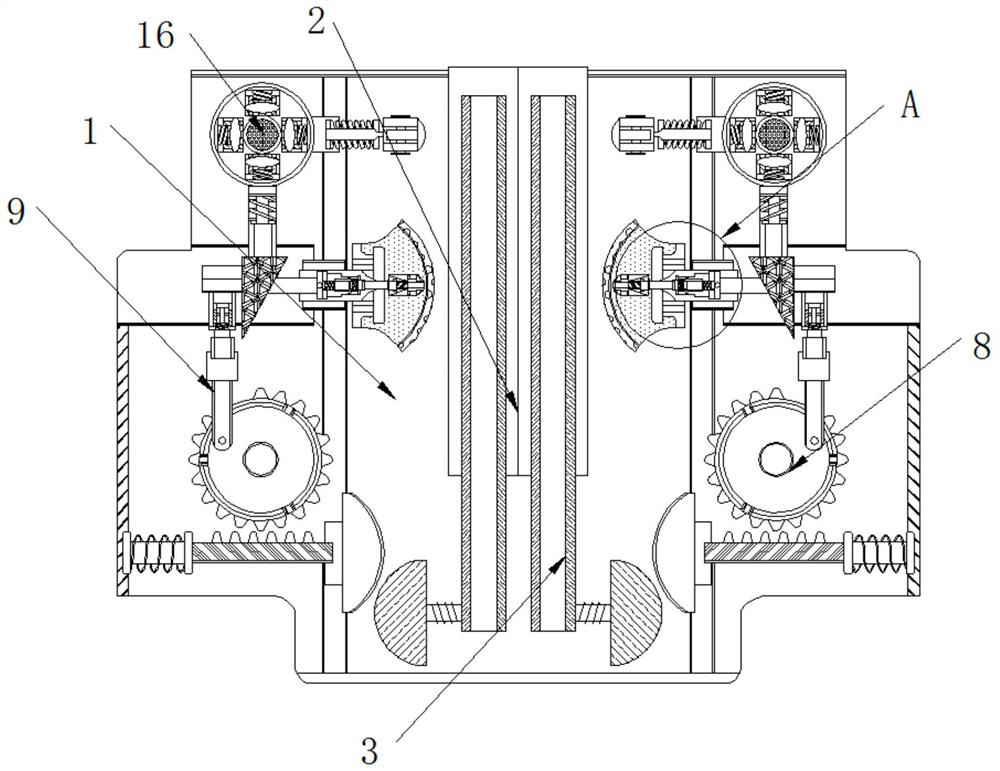

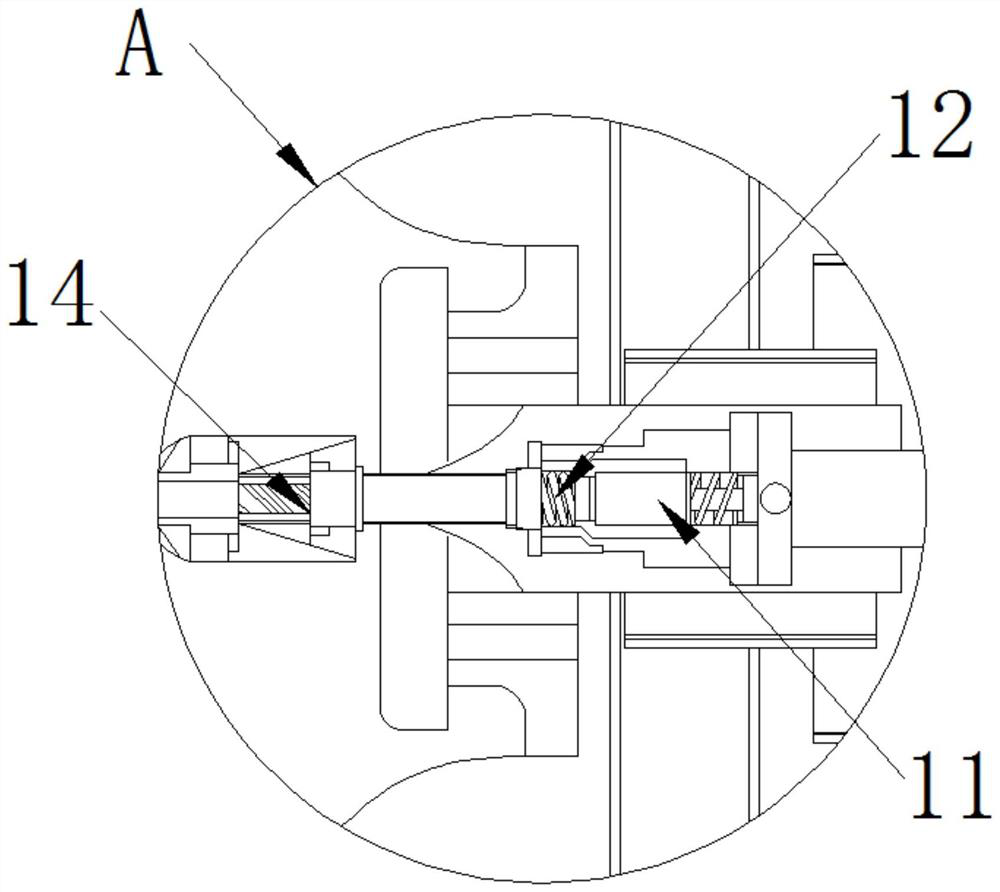

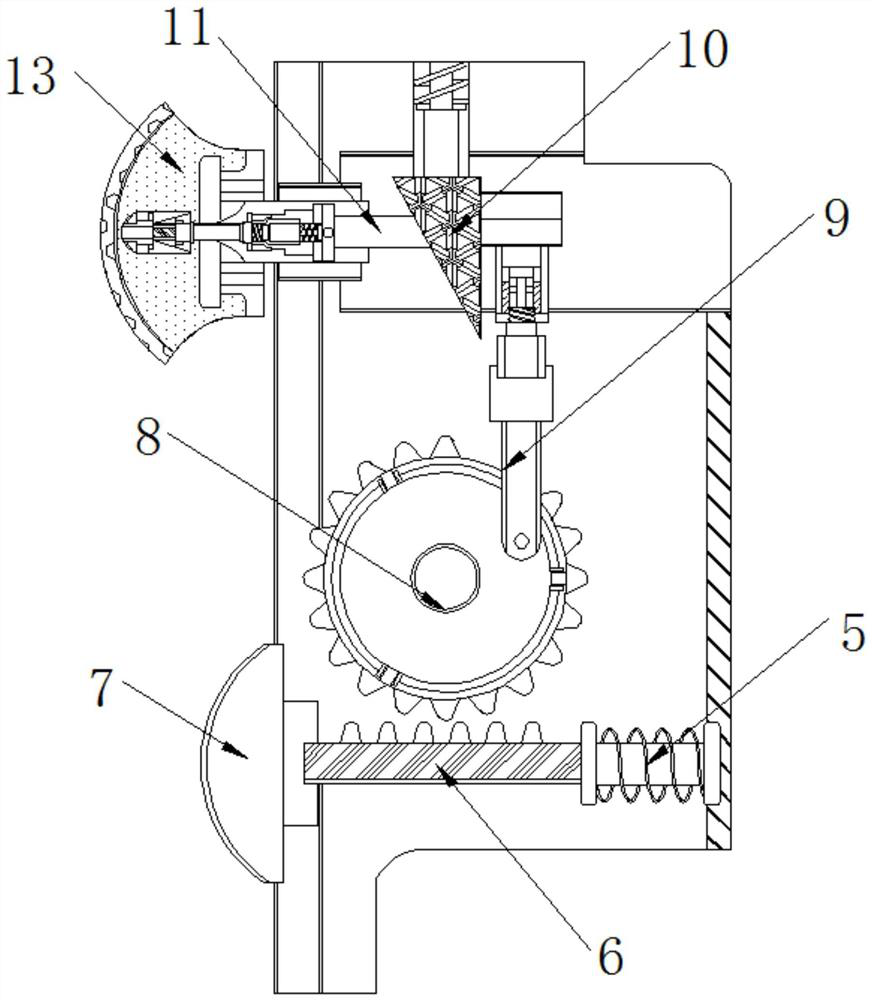

[0021] as attached figure 1 to attach Figure 5 Shown:

[0022] The present invention provides an energy-saving USB interface chip automatic production equipment for computers, comprising a production casing 1, a conveying plate 2 is slidably connected to the inside of the production casing 1, a positioning plate 3 is movably connected to the interior of the conveying plate 2, and the positioning plate 3 The outer surface of the production shell 1 is movably connected with an arc-shaped seat 4, the inner wall of the production shell 1 is movably connected with a top holding spring 5, and the side surface of the top holding spring 5 is movably connected with a ratchet plate 6, and the side surface of the ratchet plate 6 is fixedly connected with limited The seat 7 and the side surface of the arc seat 4 are movably connected with a compression spring, the shape of the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com