Cable tube winding equipment and winding process

A cable tube and equipment technology, applied in the field of cable tube winding equipment and winding technology, can solve the problems of easy dripping of glue, low work efficiency, and difficulty in cleaning, so as to avoid troublesome cleaning, improve work efficiency, and reduce occupation The effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

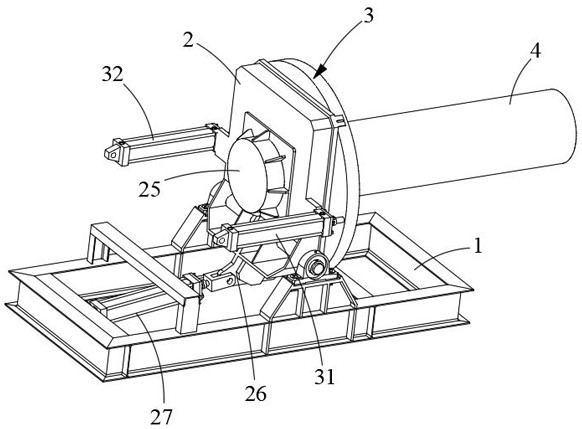

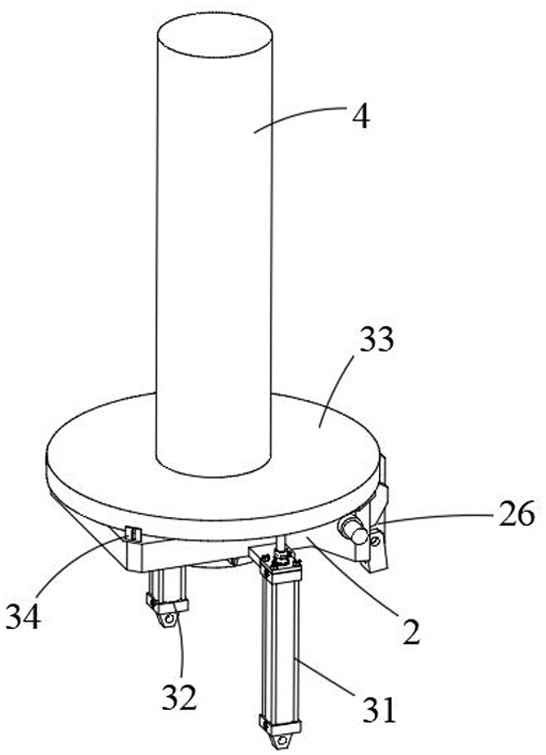

[0050] like Figure 1 to Figure 6As shown, the present invention provides a cable tube winding device, including a fixing frame 1, a base 2, a gluing part 3 and a support column 4, the base 2 is hinged on the upper end of the fixing frame 1; push the base 2 , the base 2 can be rotated axially with the hinge point as the axis, so that the base 2 is in a vertical or horizontal state; the support column 4 is rotatably arranged on the base 2, and the support column 4 The length of the cable tube is not less than the length of the cable tube to be processed, so that when gluing the outer wall of the cable tube and winding the fiberglass, the support column 4 can support and fix the cable tube; meanwhile, the support column 4 is provided with a heating resistance wire inside, In this way, when the glue is coated on the outer wall of the cable tube, the support column 4 continues to heat the cable tube, which can effectively prolong the curing time of the glue. The gluing part 3 is ...

Embodiment 2

[0058] On the basis of the first embodiment, the second embodiment also provides a winding process for a circuit tube winding device, including the circuit tube winding device described in the first embodiment. The specific structure is the same as that of the first embodiment. Without further elaboration, a specific winding process of a circuit tube winding device is as follows:

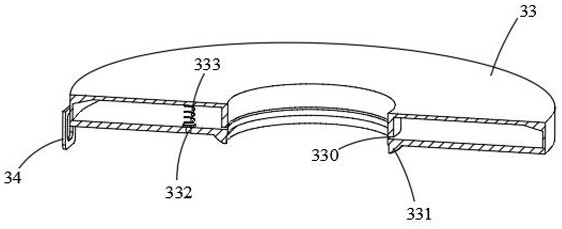

[0059] After the cable tube is sleeved on the outer wall of the support column 4 and one end is in contact with the base 2, the cylinder 27 is pushed to drive the base 2 to rotate 90° with the hinge point as the axis, so that the support column 4 is in a vertical state; the first driving cylinder 31 and The second driving cylinder 32 synchronously drives the glue storage bin 33 from both sides of the glue storage bin 33 to move upward along the axial direction of the support column 4 , so that the glue in the glue storage bin 33 flows from the glue outlet 330 to the cable tube The outer wall is coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com