A method for adjusting the assembly clearance of magnetic bearings, auxiliary bearings and rotors

A kind of auxiliary bearing and magnetic bearing technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems such as the assembly method of the magnetic bearing and the auxiliary bearing or the gap adjustment is not in place, the auxiliary bearing has no protective effect, and the magnetic bearing is damaged. , to achieve the effect of reducing design difficulties, facilitating control and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

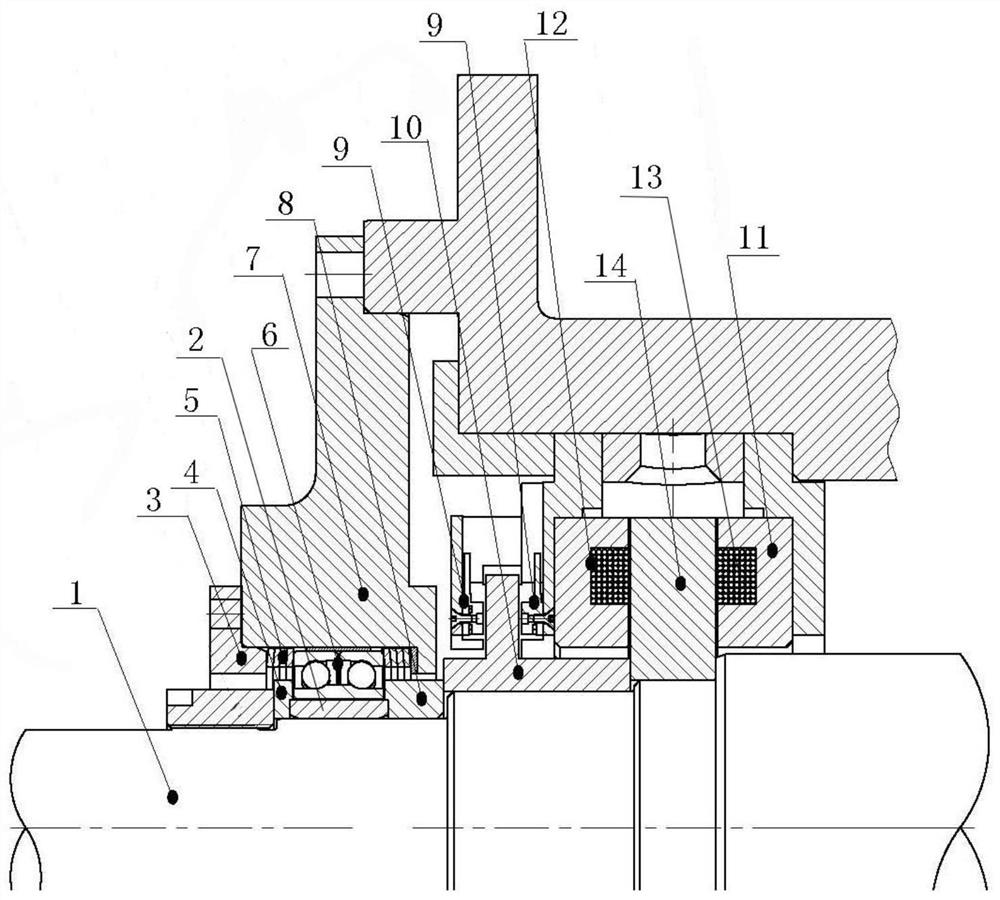

[0043] Such as Figure 1 to Figure 6 As shown, a method for adjusting the assembly gap between the magnetic bearing, the auxiliary bearing and the rotor comprises the following steps:

[0044] S1 Prepare the following parts, such as figure 1 shown

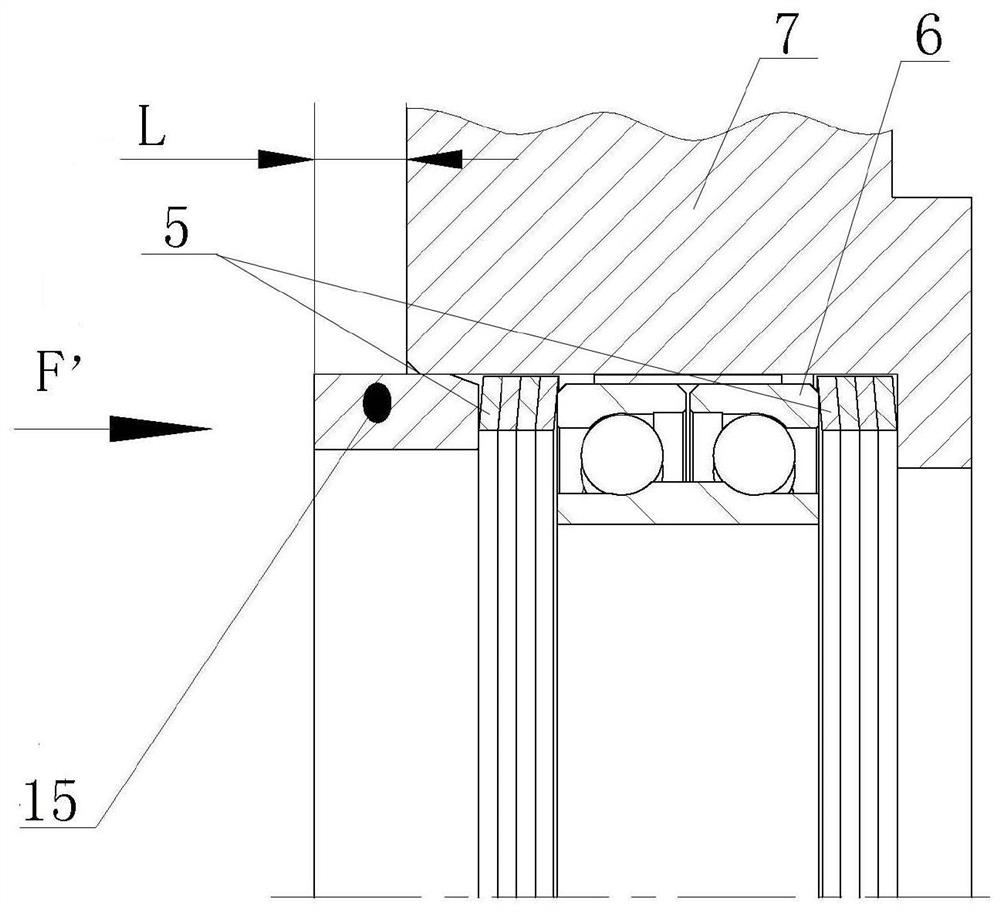

[0045] Magnetic bearing 11, rotor 1, thrust plate 14, sensor measuring body 10, displacement sensor 9, auxiliary bearing 6, protective cover 2, spring lamination 5, bearing housing 7, left adjustment block 4, right adjustment block 8; The bearing 11 is provided with a left side coil 12 and a right side coil 13;

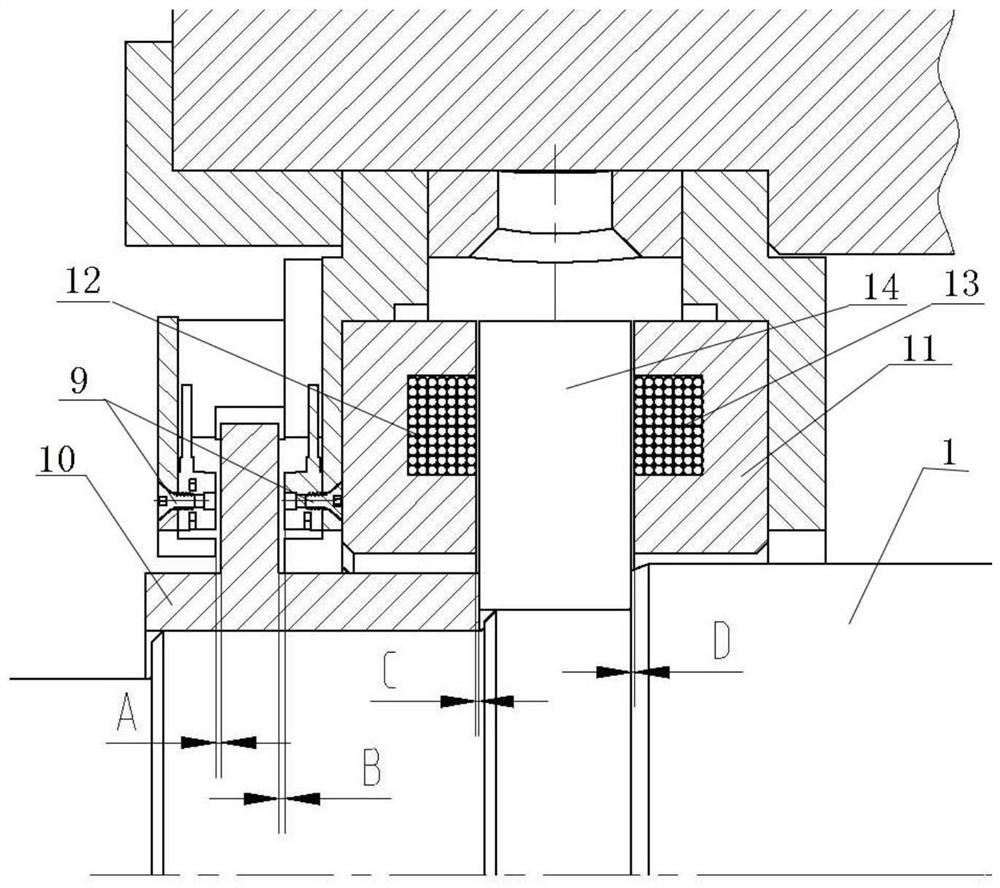

[0046] S2 Gap adjustment between magnetic bearing 11 and rotor 1, such as figure 2 shown

[0047] S21 install the thrust plate 14 and the sensor measuring body 10 on the stepped shaft of the rotor 1, the sensor measuring body 10 is located on the left side of the thrust plate 14, the thrust plate 14 and the sensor measuring body 10 move axially synchronously with the rotor 1, and the magnetic bearing 11 Sleeved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com