Power equipment fault monitoring method based on mutual reconstruction single-class auto-encoder

A self-encoder and power equipment technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as low work efficiency, high equipment requirements, loss, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

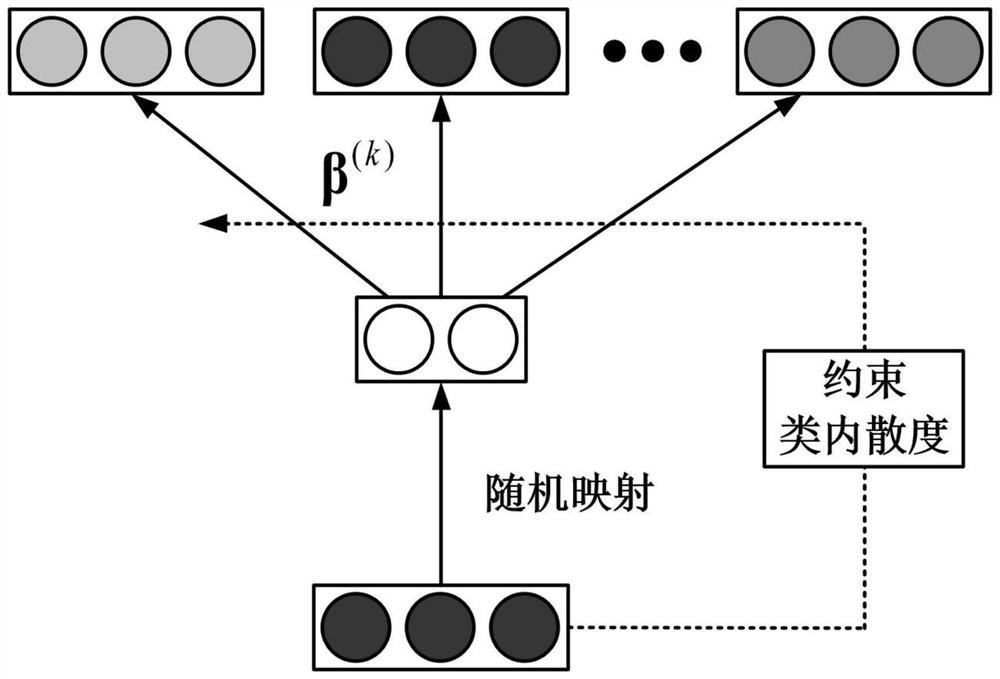

[0047] The invention relates to a power equipment fault monitoring method based on a mutual reconstruction single-class self-encoder. like figure 1 As shown, the method of the present invention includes the following steps.

[0048]Step 1: Collect the magnetic field information of the power equipment in normal operation as the training data sample set.

[0049] Step 2: Perform preprocessing such as frame division, windowing, and noise reduction on the collected data samples, and obtain a training data sample set of N data samples [X] D×N =[x 1 … x N ], where D is the dimensionality of each data sample. N is the number of training data samples.

[0050] Step 3: Assume that a total of 2 mutual reconstruction single-class random autoencoders WSI-GAE are used, and the training data sample set X i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com