Full-automatic poultry nipple waterer assembling device and assembling method

A fully automated, assembly device technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and high work intensity, achieve stable and reliable installation, improve production efficiency, and increase the degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

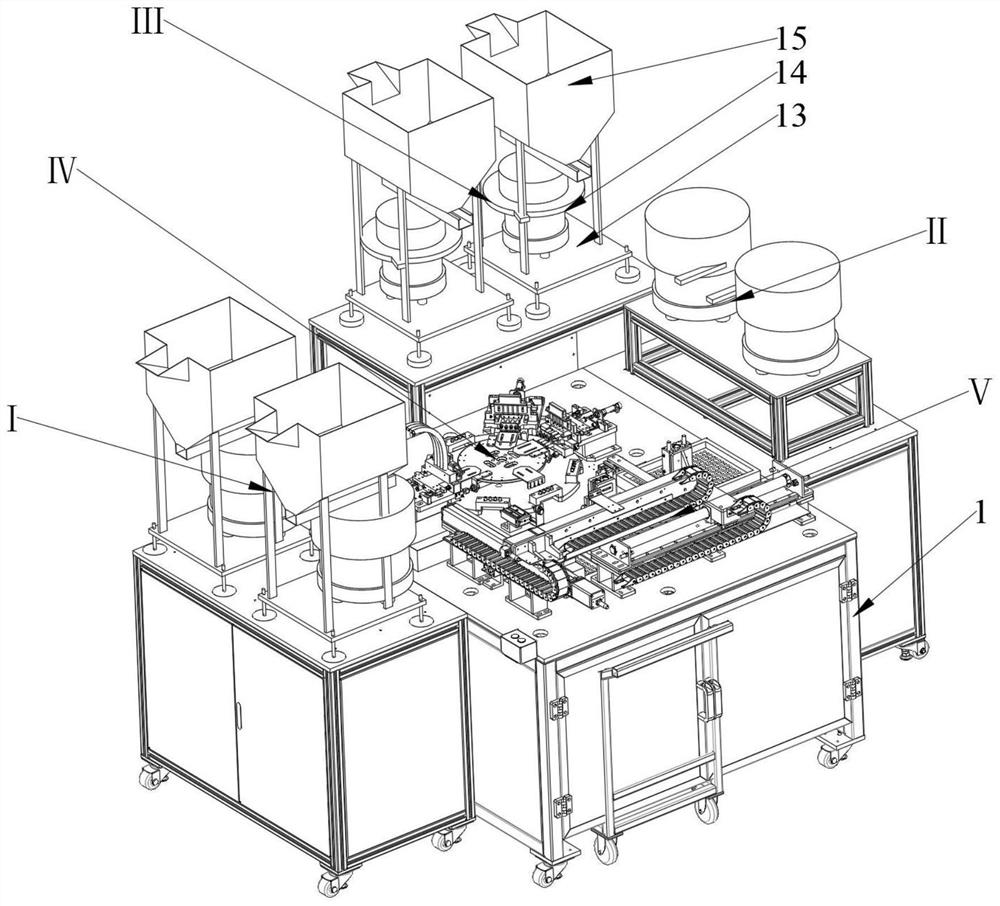

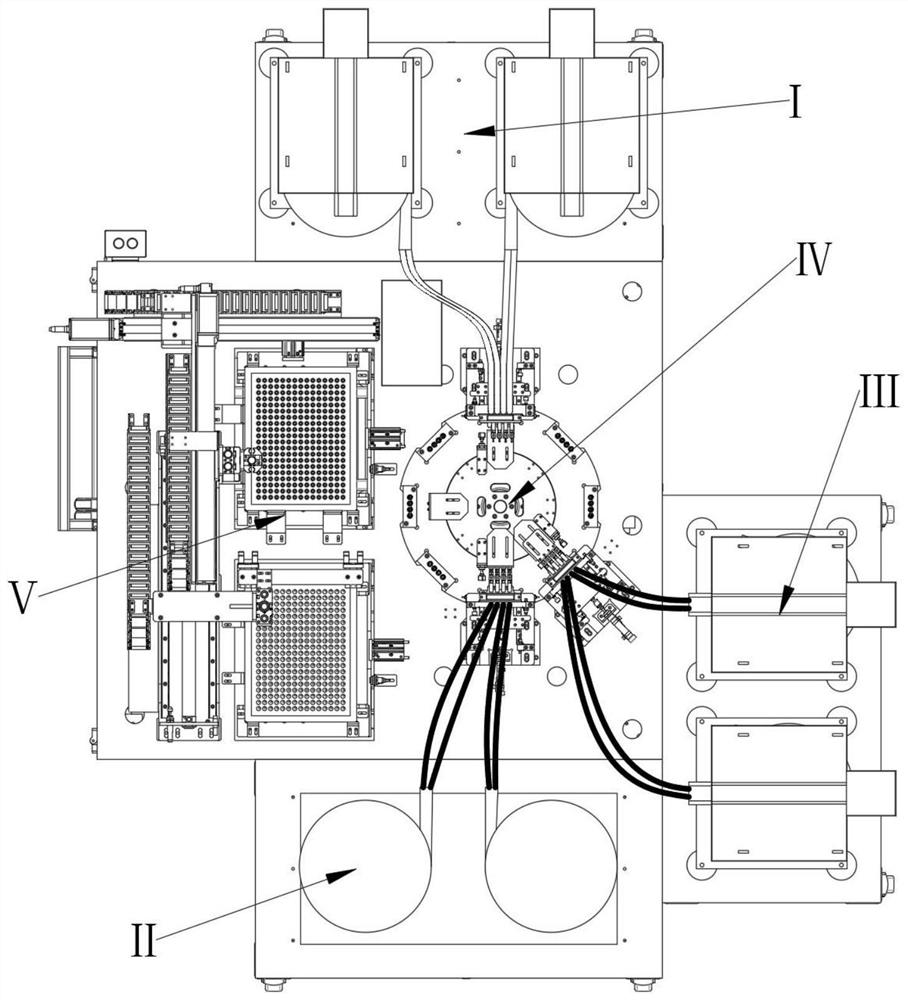

[0041] Such as figure 2 and 3 As shown, a fully automatic nipple drinker assembly device for poultry, including frame 1, plastic parts feeding mechanism I, large valve stem feeding mechanism II, small valve stem feeding mechanism III, assembly operation device IV and unloading Apparatus V. The assembly operating device IV and the unloading device V are installed side by side on the frame 1; the plastic part feeding mechanism I, the large valve stem feeding mechanism II, and the small valve stem feeding mechanism III surround the assembly operating device IV and the unloading device V outside.

[0042] The plastic part feeding mechanism I, the large valve stem feeding mechanism II, and the small valve stem feeding mechanism III all include a feeding frame 13 and two vibrating feeding trays 14 . Two vibrating feeding trays 14 are installed on the feeding frame 13 . Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com