Multi-layer ship cross-layer lifting device and assembling method thereof

A technology for lifting devices and lifting components, which is applied to ship components, ship construction, transportation and packaging, etc., and can solve problems such as uneven thickness, long processing time, and small contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

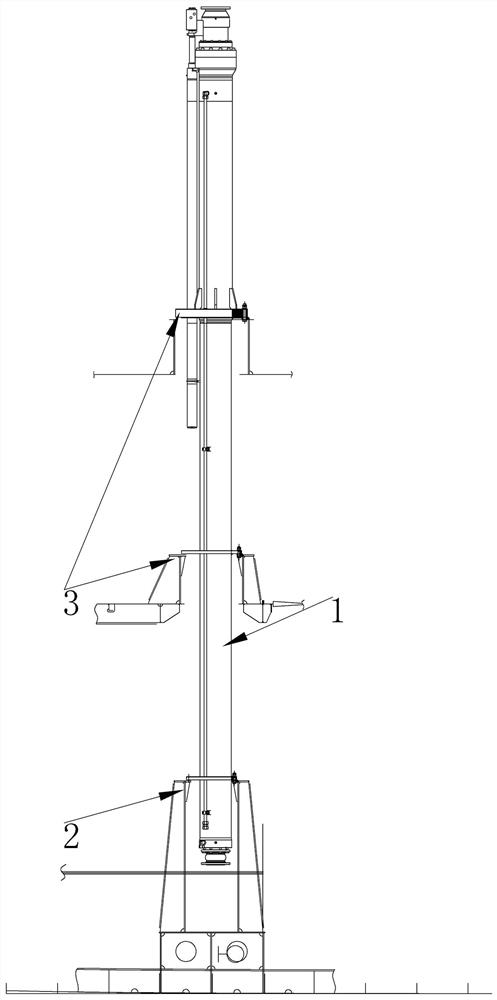

[0024] Such as figure 1 As shown, in this embodiment, the multi-layer ship cross-floor lifting device includes a lifting assembly 1, a base mounting base 2 and at least two sets of layer-crossing mounting bases 3, and the base mounting base 2 is fixed on the ship deck. The layer-through base is arranged on the floor of the floor where the lifting assembly 1 passes through, the base-level installation base 2 and all the layer-through installation bases 3 are arranged coaxially, the bottom of the lifting assembly 1 and the base-level installation base 2 is fixedly connected, and a first epoxy resin gasket is poured between the layer-through installation base 3 and the lifting assembly 1.

[0025] In this embodiment, the lifting assembly 1 includes a hydraulic cylinder, the bottom of the hydraulic cylinder is provided with a first connection flange connected to the base installation base 2, and the hydraulic cylinder is also provided with a corresponding The second connection fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com