Novel gas nozzle with sufficient combustion

A gas nozzle and sufficient combustion technology, applied in the direction of combustion type, burner, combustion method, etc., can solve the problems of uneven mixing of primary gas mixture, no buffer stage, insufficient combustion, etc., to achieve smooth gas supply and avoid energy waste , full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

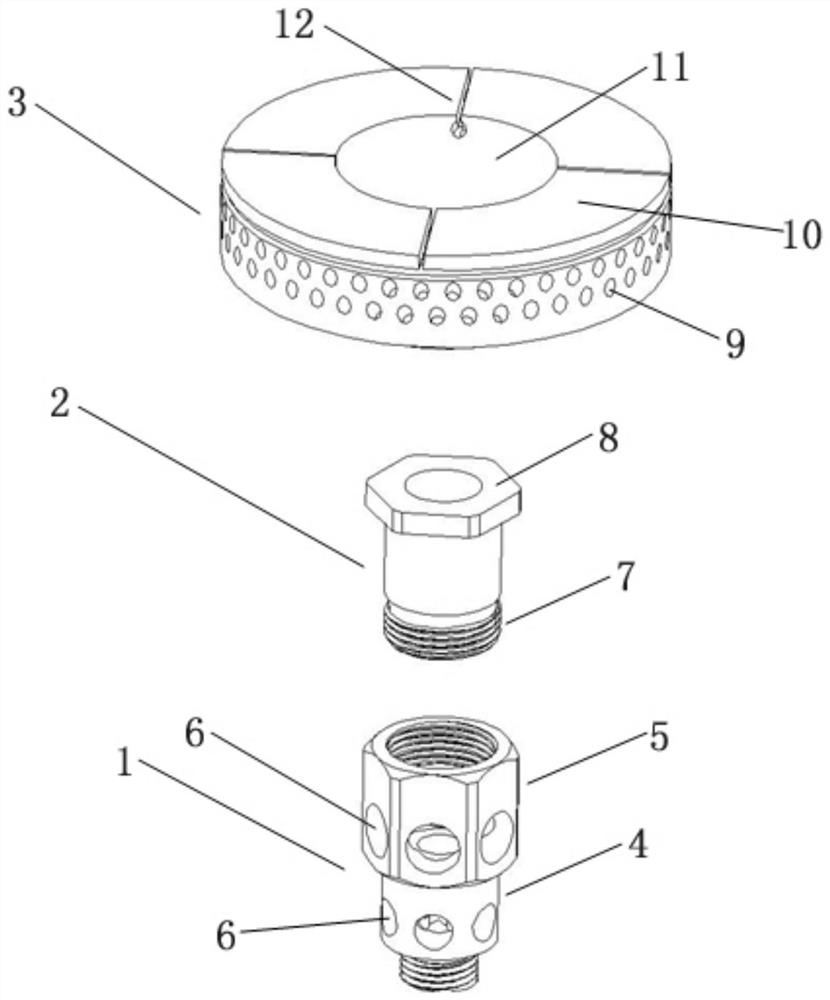

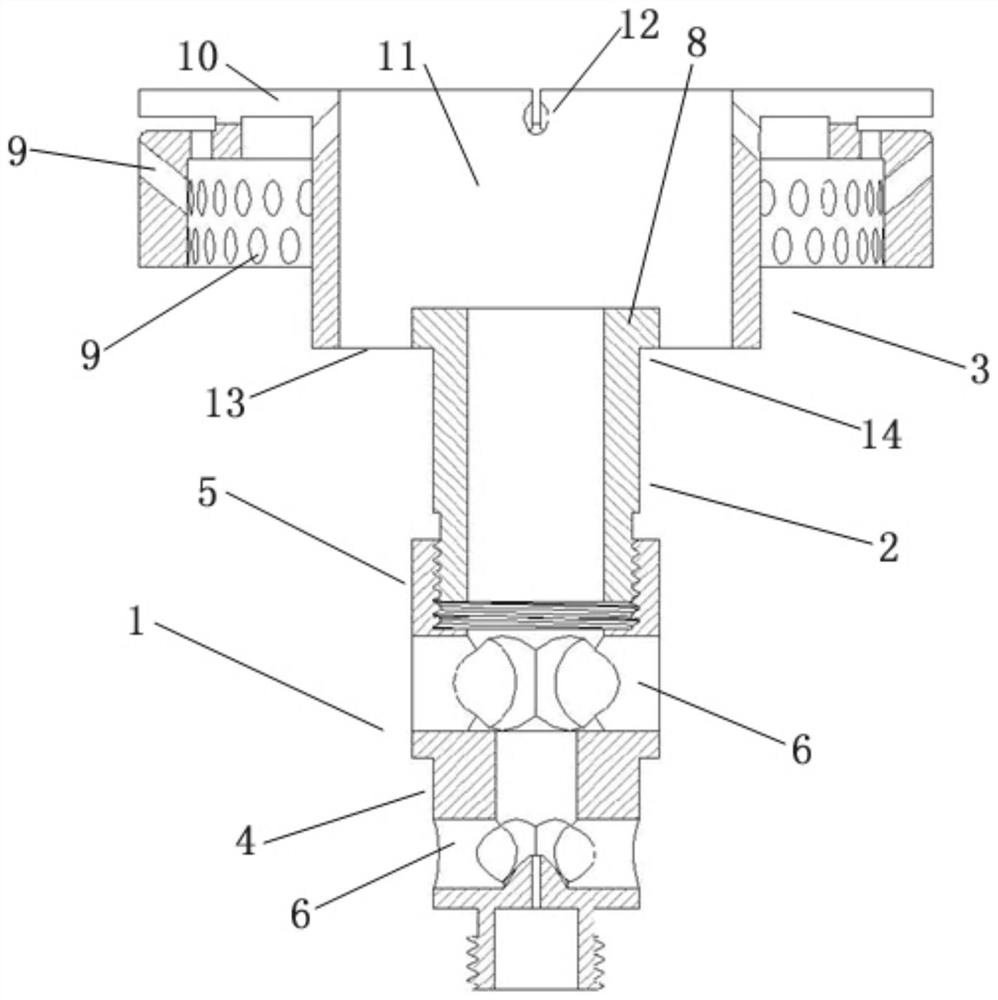

[0015] Such as figure 1 and figure 2 As shown, a new gas nozzle with sufficient combustion of the present invention includes a gas mixing chamber 1 , a gas mixing extension chamber 2 and a gas flame dragger 3 arranged in sequence from bottom to top.

[0016] The gas mixing chamber 1 and the gas mixing extension chamber 2 are screwed together by threads 7;

[0017] After the bottom of the gas-mixing extension chamber 2 passes through the circular cavity 11 at the top of the gas-flame tractor 3, the hexagonal top surface 8 on the top is covered by the outer circumference of the air inlet through hole 14 at the bottom of the gas-flame tractor 3. The circular boss 13 is blocked, so that the mixed gas extension chamber 2 and the gas flame dragger 3 are combined together.

[0018] The air mixing chamber 1 is a hollow structure, including a lower air mixing chamber 4 and an upper air mixing chamber 5, and the outer walls of the lower air mixing chamber 4 and the upper air mixing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com