Inductor detection equipment

A technology for detection equipment and inductors, which is applied in the field of inductors, can solve the problems of the deviation of the efficiency of the conversion of sensor electric energy into magnetic energy, and the effect of affecting the detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

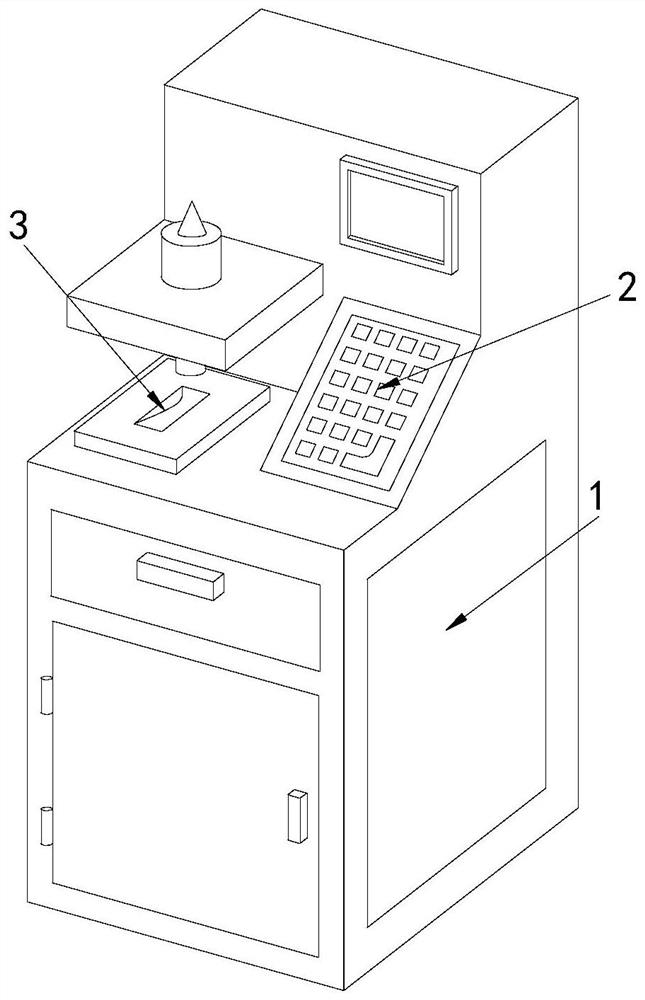

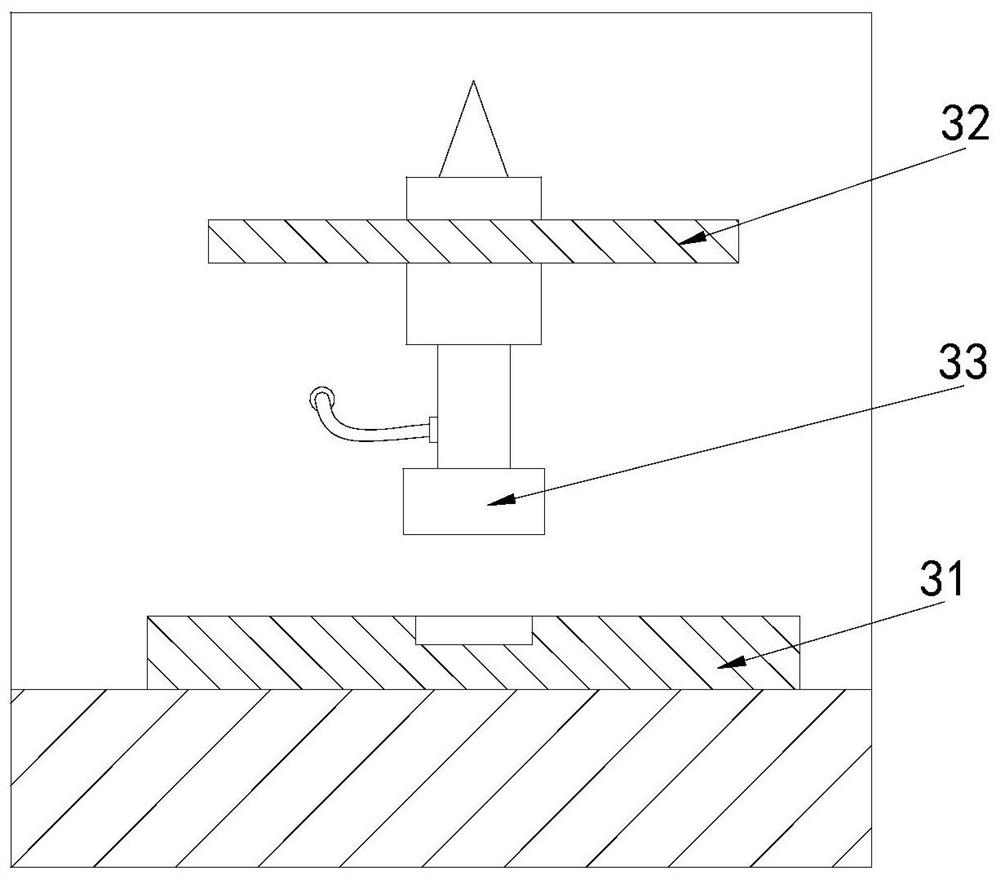

[0027] Its structure includes a main body 1, a control panel 2, and a workbench 3. The top of the main body 1 is provided with a control panel 2, and the workbench 3 is arranged on the top side of the main body 1. The workbench 3 includes a discharge plate 31 , a support plate 32, a detection device 33, the discharge plate 31 is fixed on the upper surface of the workbench 3, a detection device 33 is installed in the middle of the support plate 32, and the detection device 33 is installed vertically.

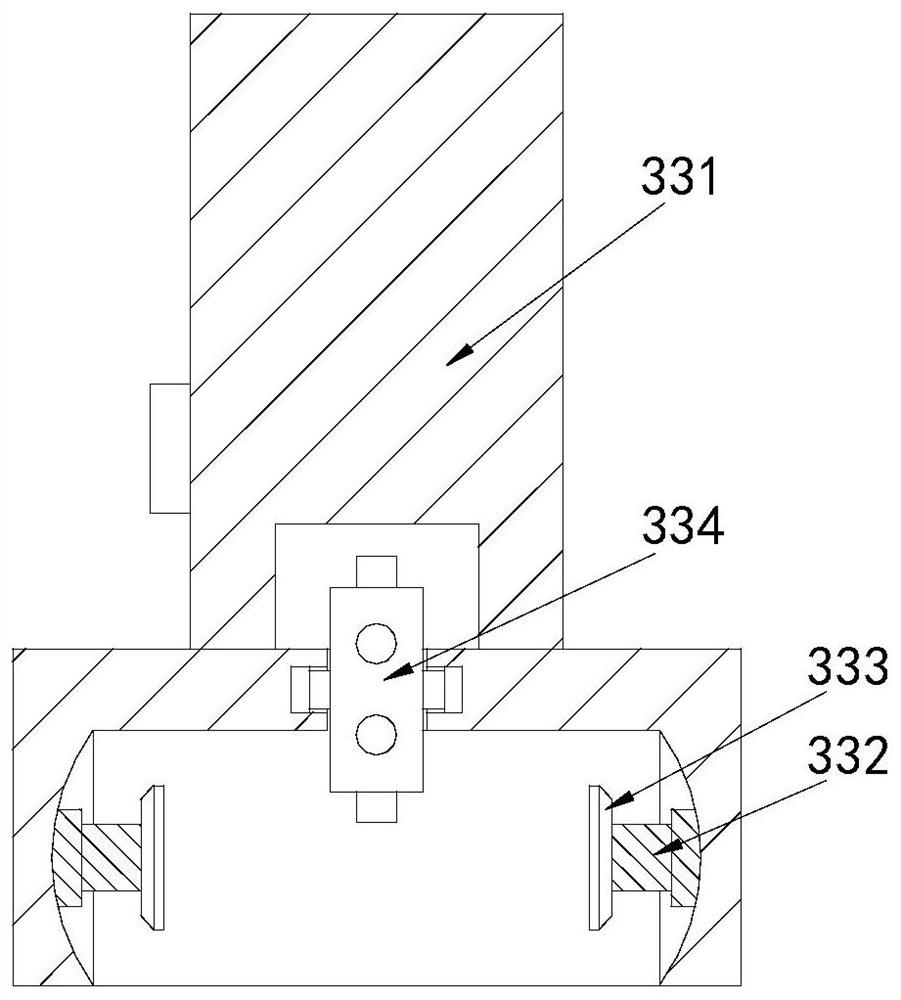

[0028] The detection device 33 includes a telescopic arm 331, a telescopic rod 332, a clamping head 333, and a detection wheel 334. The two ends of the bottom of the telescopic arm 331 are provided with a telescopic rod 332, and the end of the telescopic rod 332 is provided with a clamping head. 333, the end face of the clamping head 333 is circular, the det...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The detection head a64 includes a movable groove b1, a detection piece b2, a tension spring b3, and a limit block b4, the movable groove b1 is arranged at the inner end of the detection head a64, two detection pieces b2 are provided, and Fitting inside the movable groove b1, the tension spring b3 connects the two detection pieces b2, the limit block b4 is arranged on the inner top of the two detection pieces b2, the tension spring b3 and the detection piece b2 The movable cooperation facilitates the expansion and contraction of the distance between the two detection pieces b2, so that the detection piece b2 can be easily inserted into the gap of the coil.

[0034] The detection piece b2 includes a detection body b21, a rubber block b22, a cavity b23, and a rubber pad b24. The bottom end of the detection body b21 is embedded with a rubber block b22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com